Sustained-release oxygen microsphere as well as preparation method and application thereof

A technology of microspheres and oxygen release, applied in microcapsules, pharmaceutical formulations, medical science, etc., can solve the problems of large volume of oxygen release materials, complicated preparation process, no solution, etc., achieve great application prospects, simple preparation process, Effects with controllable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

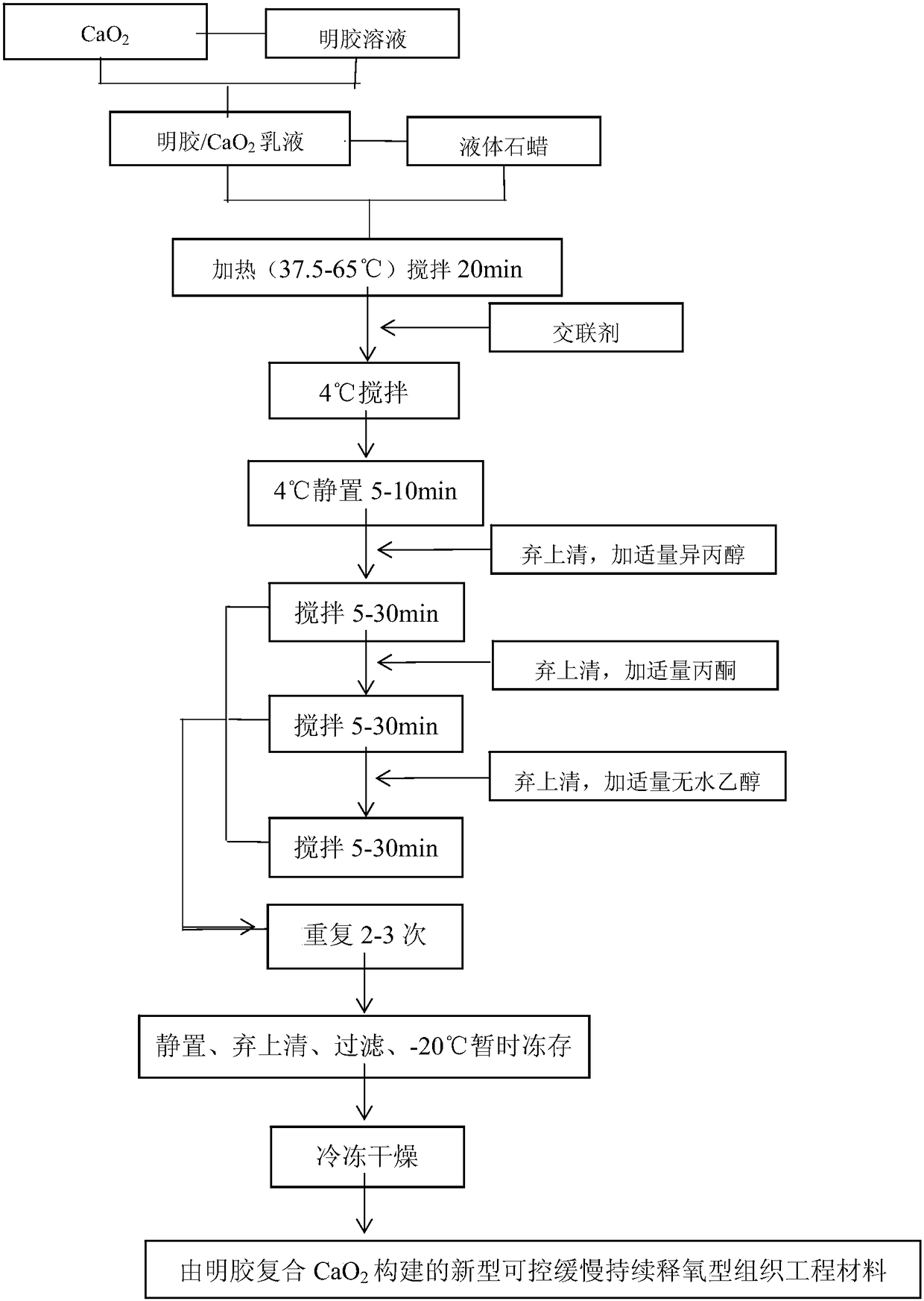

Method used

Image

Examples

Embodiment 1

[0084] Example 1 Preparation of oxygen-releasing microspheres

[0085] 1) Preparation of gelatin solution: prepare a gelatin solution with a concentration of 0.8g / ml, the specific method is as follows:

[0086] ①Weigh 8g of gelatin into a beaker, then add 10ml of PBS, place on a magnetic stirrer and stir at 500rpm for about 5min;

[0087] ②Seal ① with disposable sterile parafilm, place at 54°C to fully dissolve the gelatin in PBS (50min), and set aside;

[0088] Preparation of nanofiber film: prepare a hexafluoroisopropanol solution of collagen powder, and make the solution into a nanofiber film for in vivo experiments;

[0089] 2) Preparation of liquid paraffin dispersed phase: the specific method is as follows:

[0090] ①Preheat the liquid paraffin at 54°C for 1 hour;

[0091] ② Take 100ml into a 250ml beaker, place it on a heating magnetic stirrer (54°C), stir at 1500rpm, add 1ml of emulsifier Span80 at the same time, keep stirring, and fully emulsify for 20min;

[0092...

Embodiment 2

[0102] Example 2 Preparation of oxygen-releasing microspheres

[0103] 1) Preparation of gelatin solution: prepare a gelatin solution with a concentration of 0.8g / ml, the specific method is as follows:

[0104] ①Weigh 8g of gelatin into a beaker, then add 10ml of PBS, place on a magnetic stirrer and stir at 500rpm for about 5min;

[0105] ②Seal ① with disposable sterile parafilm, place at 54°C to fully dissolve the gelatin in PBS (50min), and set aside;

[0106] Preparation of nanofiber film: prepare a hexafluoroisopropanol solution of collagen powder, and make the solution into a nanofiber film for in vivo experiments;

[0107] 2) Preparation of liquid paraffin dispersed phase: the specific method is as follows:

[0108] ①Preheat the liquid paraffin at 54°C for 1 hour;

[0109] ② Take 100ml into a 250ml beaker, put it on a heating magnetic stirrer (54°C), stir at 1000rpm, add 1ml of emulsifier Span80 at the same time, keep stirring, and fully emulsify for 20min;

[0110] ...

Embodiment 3

[0120] Example 3 Preparation of oxygen-releasing microspheres

[0121] 1) Preparation of gelatin solution: prepare a gelatin solution with a concentration of 0.8g / ml, the specific method is as follows:

[0122] ①Weigh 8g of gelatin into a beaker, then add 10ml of PBS, place on a magnetic stirrer and stir at 500rpm for about 5min;

[0123] ②Seal ① with disposable sterile parafilm, place at 54°C to fully dissolve the gelatin in PBS (50min), and set aside;

[0124] Preparation of nanofiber film: prepare a hexafluoroisopropanol solution of collagen powder, and make the solution into a nanofiber film for in vivo experiments;

[0125] 2) Preparation of liquid paraffin dispersed phase: the specific method is as follows:

[0126] ①Preheat the liquid paraffin at 54°C for 1 hour;

[0127] ② Take 100ml into a 250ml beaker, place it on a heating magnetic stirrer (54°C), stir at 500rpm, add 1ml of emulsifier Span80 at the same time, keep stirring, and fully emulsify for 20min;

[0128]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com