One-dimensional metallic oxide loaded titanium-based electro-catalysis film, preparing method and catalytic application

A technology of electrocatalytic membranes and oxides, applied in chemical instruments and methods, electrodes, water pollutants, etc., can solve problems such as limitations, difficulty in controlling particle size and shape, poor catalytic performance, etc., and achieve easy control of loading capacity, Excellent electrochemical performance and simple loading method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

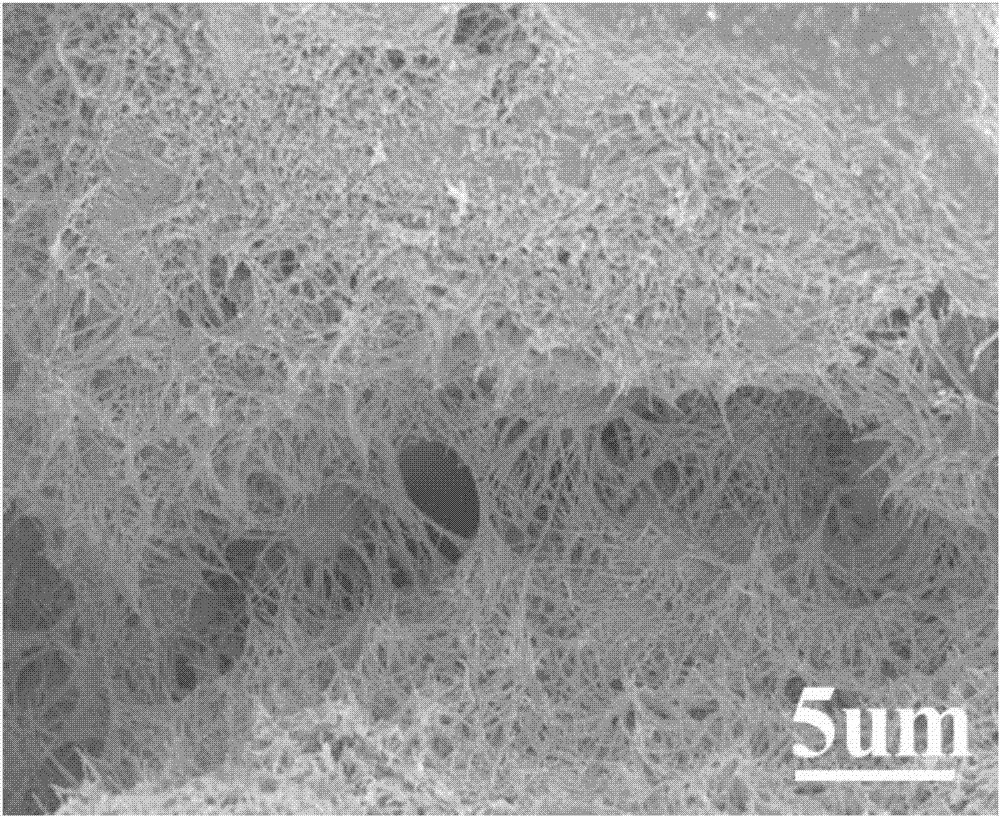

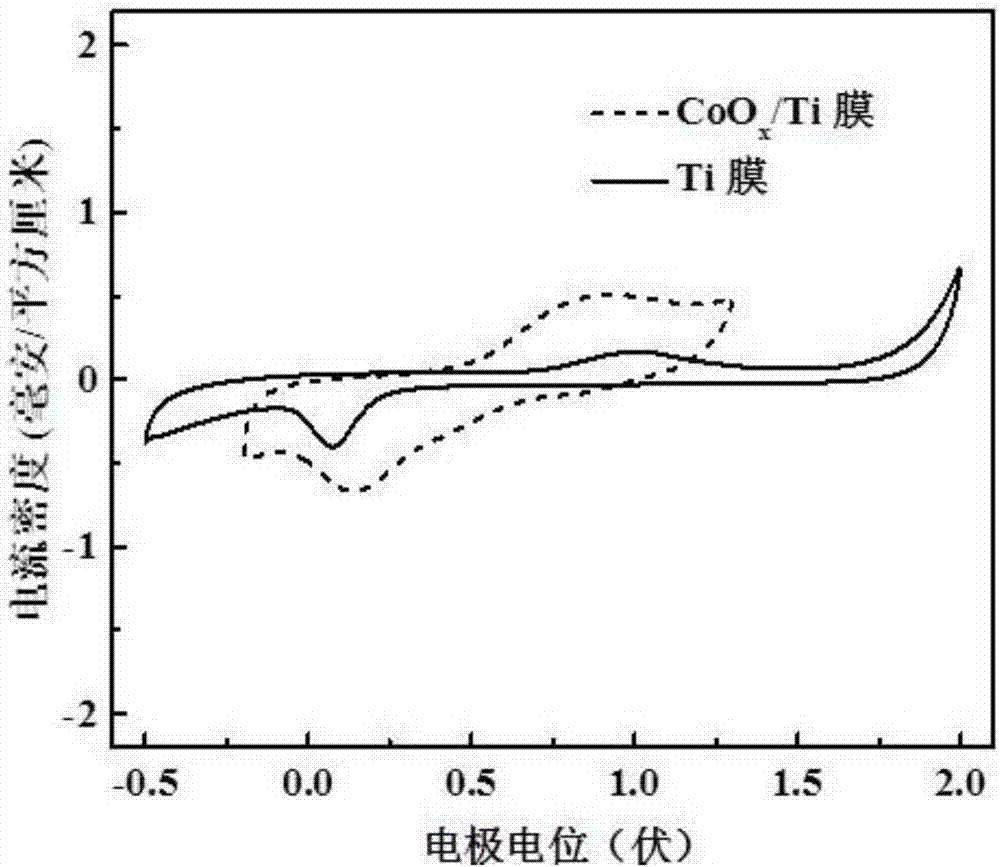

[0030] In this example, a tubular titanium membrane with an average pore diameter of 3.0 microns is used as the substrate, and CoO x It is an in-situ supported catalytic coating, and the morphology and structure are one-dimensional nanowires, and CoO is prepared by hydrothermal method x Nanowires supporting Ti-based electrocatalytic membranes in situ.

[0031] Sandblast the conductive microporous titanium film, then immerse the sandblasted titanium-based film in NaOH solution for 2 hours, wash to neutral, then immerse the alkali-washed titanium film in oxalic acid with a mass percentage concentration of 10%. Etched in the solution for 2 hours, washed with water, and dried at 110°C;

[0032] Dissolve cobalt sulfate, ammonium fluoride, and NaOH (2mmol / L) solution in ethanol at a ratio of 1:50:10 to form a precursor solution. After stirring for 2 hours at room temperature, a uniformly mixed precursor solution is prepared; then the pretreatment The final titanium film substrate ...

Embodiment 2

[0035] In this embodiment, a flat titanium film with an average pore diameter of 2.0 microns is used as the substrate, and NiO x It is an in-situ loaded catalytic coating, and the morphology is one-dimensional nanowires, and NiO is prepared by hydrothermal method. x Nanowires supporting Ti-based electrocatalytic membranes in situ.

[0036] Sandblast the conductive microporous titanium film, then immerse the sandblasted titanium-based film in NaOH solution for 2 hours, wash to neutral, then immerse the alkali-washed titanium film in oxalic acid with a mass percentage concentration of 10%. Etched in the solution for 2 hours, washed with water, and dried at 110°C;

[0037] Dissolve nickel nitrate, ammonium fluoride, and NaOH (2mmol / L) solution in ethylene glycol at a ratio of 1:60:20 to form a precursor solution. After stirring for 2 hours at room temperature, a uniformly mixed precursor solution is prepared; then The pretreated titanium film substrate is soaked in the precursor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com