Water wave type binning method

A technology of water wave and level height, applied in the field of grain storage, can solve the problems of affecting ventilation or fumigation effect, large workload of leveling grain surface, easy breeding of insects and molds, etc., and achieves unique storage method, reduced labor, and storage effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

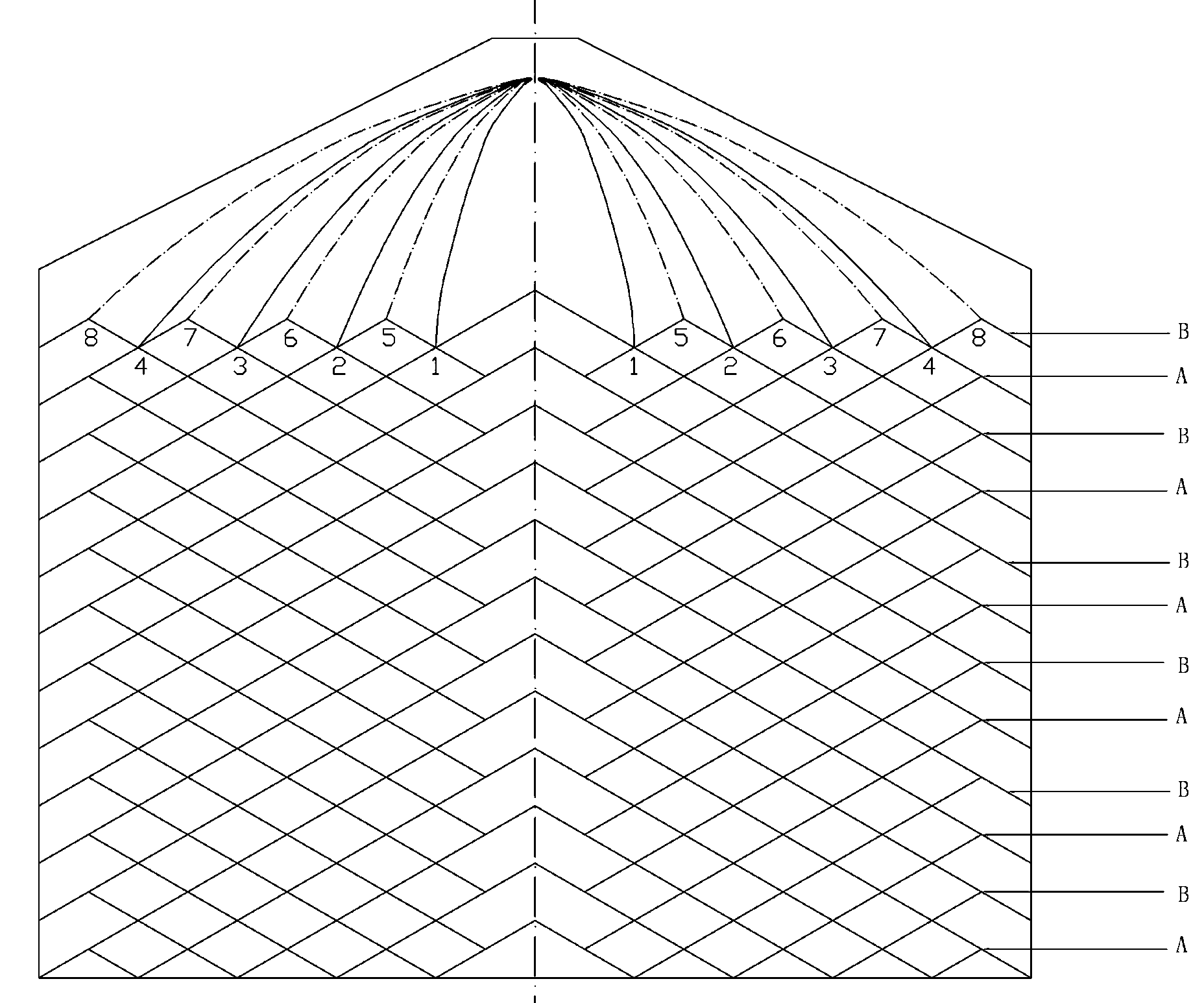

[0012] Embodiment 1: A water wave type binning method, which increases or decreases the rotational speed of the chute step by step, and relies on the centrifugal force generated by the grain itself when the chute rotates to form different projectile distances. Under the condition of constant rotational speed and projectile angle Under the action of the rotation of the chute, the grain continuously flows to the fixed ring to form a projecting ring. figure 1 Among them, the numbers 1 to 8 respectively denote projecting rings with different diameters, and control the motor speed level and time to generate multiple concentric projecting rings at the same level. For example, the control motor speeds are A 1 、A 2 、A 3 、A 4 , respectively yielding a diameter D 1 、D 2 、D 3 、D 4 The projecting ring, the ring is the crest, and the junction of the rings is the trough. When the speed of the chute is constant, the angle of projection is also constant. The throwing time of each thro...

Embodiment 2

[0013] Embodiment 2: On the basis of Embodiment 1, the rotation speed of the chute is adjusted to produce layers A and B in different grain distribution methods. A layer and B layer are arranged circularly in turn, and the peaks of the upper and lower layers match the troughs to achieve the purpose of uniform grain distribution. Usually, both the A layer and the B layer will have multiple ejection rings, that is, both the A layer and the B layer will have multiple speed levels. Each rotational speed satisfies A i i i+1 i+1 , where i=1, 2,...n; n is a natural number greater than or equal to 1. i.e. A i i 2 2 3 3 4 4 .... In addition, among the layers A and B, at least one layer contains zero rotation speed, or both layers contain two rotation speeds.

[0014] Table 1

[0015] Layer A stockpile code Ring 4 Ring 3 Ring 2 Ring 1 Layer A speed weighted value 281 205 123 6 Layer B stockpile code Ring 8 7th ring 6th ring Ring 5 Layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com