A laser melting method for the surface of vermicular graphite cast iron

A technology of vermicular graphite cast iron and laser melting, which is used in the field of laser processing to achieve the effects of preventing oxidation, good wear resistance and enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

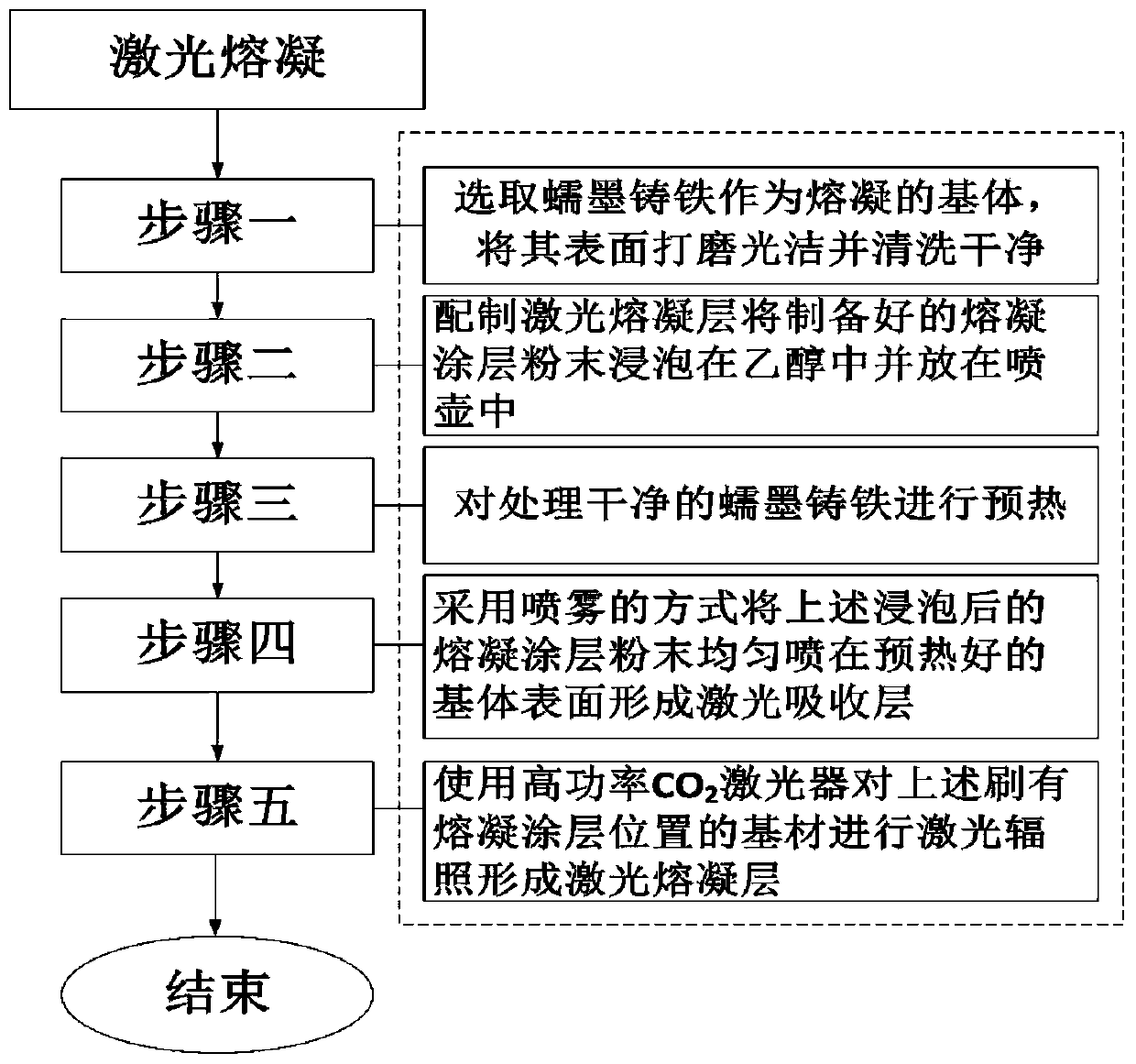

Method used

Image

Examples

Embodiment 1

[0037] (1) In step 1, the vermicular graphite cast iron substrate is cut to form a sample by wire cutting, the surface is polished with sandpaper, and then the surface of the sample is cleaned with acetone solution and dried;

[0038] (2) The laser absorbing layer powder described in step 2 is made up of compound KAlF4, k2SO4 and, Sn, Mo, V, Ti element, content is respectively

[0039] k2SO4=1.5%, Sn=0.06%, Mo=0.8%, V=2.8%, Ti=2.7%, the balance is KAlF4, mix all ingredients evenly and soak in ethanol and put in a watering can;

[0040] (3) Use a heating furnace to preheat the vermicular graphite cast iron, the preheating temperature is 350°C, and the preheating time is 10 minutes;

[0041] (4) Spread the prepared laser absorbing layer evenly on the surface of the substrate by spraying, with a thickness of 0.4mm sprayed on the substrate, and wait for the absorbing layer to dry;

[0042] (5) Use a CO2 laser to irradiate the above-mentioned laser absorbing layer with laser outpu...

Embodiment 2

[0044] (1) Step 1: In step 1, the vermicular graphite cast iron substrate is cut to form a sample by wire cutting, the surface is polished with sandpaper, and then the surface of the sample is cleaned with acetone solution and dried;

[0045] (2) The laser absorbing layer powder described in step 2 is made up of compound K3AlF6, k2SO4 and, RE, Mo, B, Ti element, and content is respectively

[0046] k2SO4=1.5%, Re=0.05%, Mo=0.8%, B=1.5%, Ti=2.7%, the balance is K3AlF6, mix all ingredients evenly and soak in ethanol and put in the watering can;

[0047] (3) Use a heating furnace to preheat the vermicular graphite cast iron, the preheating temperature is 350°C, and the preheating time is 10 minutes;

[0048] (4) Spread the prepared laser absorbing layer evenly on the surface of the substrate by spraying, with a thickness of 0.5mm sprayed on the substrate, and wait for the absorbing layer to dry;

[0049] (5) Use a CO2 laser to irradiate the above-mentioned laser absorbing layer ...

Embodiment 3

[0051] (1) Step 1: In step 1, the vermicular graphite cast iron substrate is cut to form a sample by wire cutting, the surface is polished with sandpaper, and then the surface of the sample is cleaned with acetone solution and dried;

[0052] (2) The laser absorbing layer powder described in step 2 is made up of compound K3AlF6, k2SO4 and Cr, Mo, Cu, V element, content is respectively

[0053] K3AlF6, k2SO4 and Cr, Mo, Cu, V element composition, the contents are:

[0054] k2SO4=1.5%, Cr=0.3%, Mo=0.8%, Cu=0.4%, V=2.8%, the balance is K3AlF6, mix all the components evenly and soak in ethanol and put in the watering can;

[0055] (3) Use a heating furnace to preheat the vermicular graphite cast iron, the preheating temperature is 350°C, and the preheating time is 10 minutes;

[0056] (4) Spread the prepared laser absorbing layer evenly on the surface of the substrate by spraying, with a thickness of 0.6mm sprayed on the substrate, and wait for the absorbing layer to dry;

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com