Vermicular graphite cast iron surface laser melting-solidifying method

A technology of vermicular graphite cast iron and laser melting, which is used in the field of laser processing to prevent oxidation, reduce thermal stress, and enhance oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

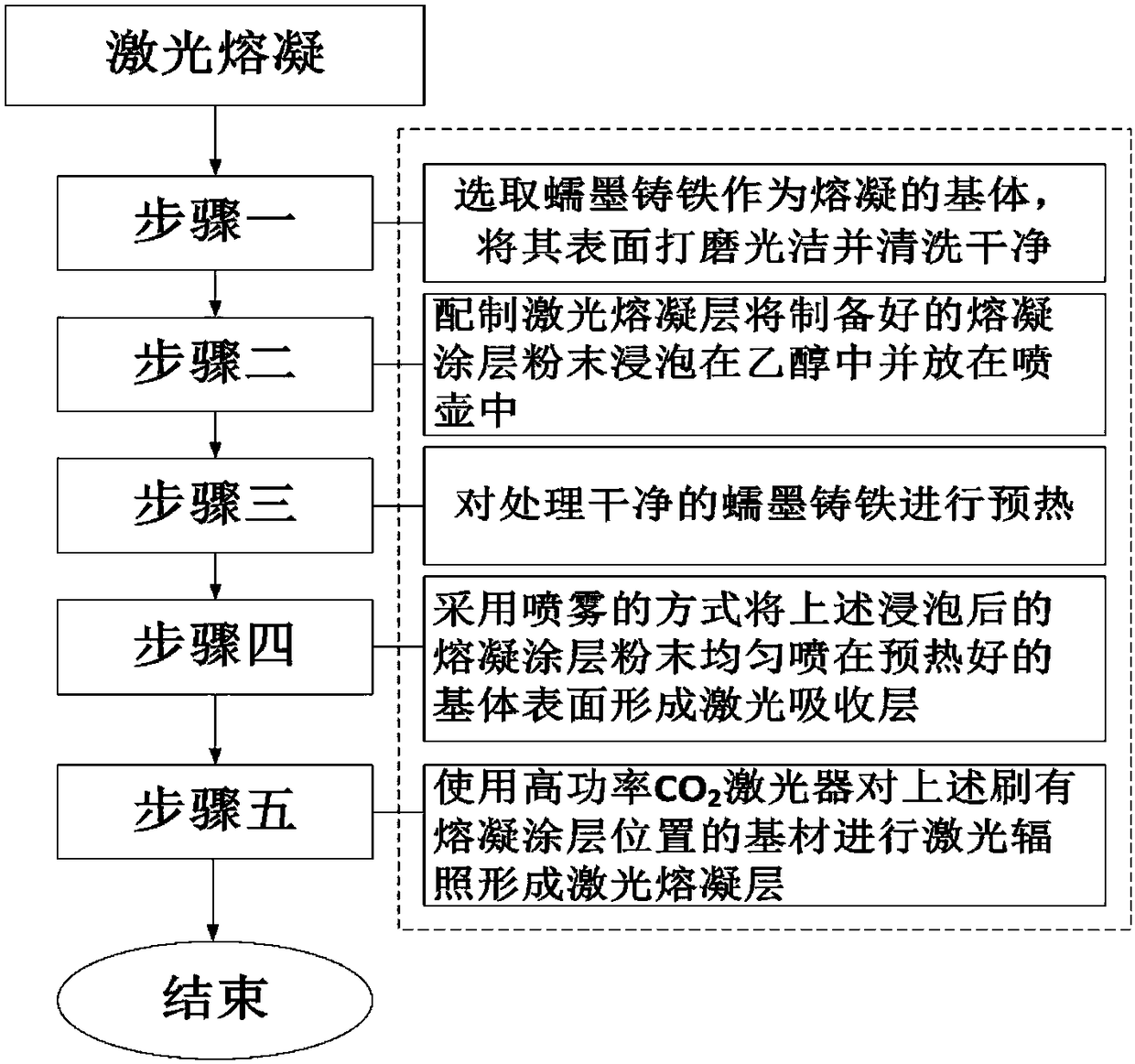

Method used

Image

Examples

Embodiment 1

[0037] (1) In step 1, the vermicular graphite cast iron substrate is cut to form a sample by wire cutting, the surface is polished with sandpaper, and then the surface of the sample is cleaned with acetone solution and dried;

[0038] (2) the laser absorbing layer powder described in step 2 is made up of compound KAlF4, k2SO4 and, Sn, Mo, V, Ti element, content is respectively

[0039] k2SO4=1.5%, Sn=0.06%, Mo=0.8%, V=2.8%, Ti=2.7%, the balance is KAlF4, mix all ingredients evenly and soak in ethanol and put in a watering can;

[0040] (3) Use a heating furnace to preheat the vermicular graphite cast iron, the preheating temperature is 350°C, and the preheating time is 10 minutes;

[0041] (4) Spread the prepared laser absorbing layer evenly on the surface of the substrate by spraying, with a thickness of 0.4mm sprayed on the substrate, and wait for the absorbing layer to dry;

[0042] (5) Use a CO2 laser to irradiate the above-mentioned laser absorbing layer with laser outpu...

Embodiment 2

[0044] (1) Step 1: In step 1, the vermicular graphite cast iron substrate is cut to form a sample by wire cutting, the surface is polished with sandpaper, and then the surface of the sample is cleaned with acetone solution and dried;

[0045] (2) the laser absorption layer powder described in step 2 is made up of compound K3AlF6, k2SO4 and, RE, Mo, B, Ti element, and content is respectively

[0046] k2SO4=1.5%, Re=0.05%, Mo=0.8%, B=1.5%, Ti=2.7%, the balance is K3AlF6, mix all ingredients evenly and soak in ethanol and put in the watering can;

[0047] (3) Use a heating furnace to preheat the vermicular graphite cast iron, the preheating temperature is 350°C, and the preheating time is 10 minutes;

[0048] (4) Spread the prepared laser absorbing layer evenly on the surface of the substrate by spraying, with a thickness of 0.5mm sprayed on the substrate, and wait for the absorbing layer to dry;

[0049] (5) Use a CO2 laser to irradiate the above-mentioned laser absorbing layer...

Embodiment 3

[0051] (1) Step 1: In step 1, the vermicular graphite cast iron substrate is cut to form a sample by wire cutting, the surface is polished with sandpaper, and then the surface of the sample is cleaned with acetone solution and dried;

[0052] (2) The laser absorbing layer powder described in step 2 is composed of compounds K3AlF6, k2SO4 and Cr, Mo, Cu, V elements, and the contents are respectively

[0053] K3AlF6, k2SO4 and Cr, Mo, Cu, V element composition, the contents are:

[0054] k2SO4=1.5%, Cr=0.3%, Mo=0.8%, Cu=0.4%, V=2.8%, the balance is K3AlF6, mix all the components evenly and soak in ethanol and put in the watering can;

[0055] (3) Use a heating furnace to preheat the vermicular graphite cast iron, the preheating temperature is 350°C, and the preheating time is 10 minutes;

[0056] (4) Spread the prepared laser absorbing layer evenly on the surface of the substrate by spraying, with a thickness of 0.6mm sprayed on the substrate, and wait for the absorbing layer to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com