Preparation method and application of carbon-loaded platinum cobalt nanometer alloy catalyst

An alloy catalyst, cobalt nanotechnology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of limiting the commercialization process of fuel cells, the scarcity of Pt resources, and the high cost of catalysts. The effect of uniform size, good dispersion and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the preparation method of this carbon-supported platinum-cobalt nano-alloy catalyst, concrete operations are as follows:

[0035] (1) Take 60mg of platinum acetylacetonate, 12.3mg of cobalt acetate, Po:Co=3:1, dissolve in 0.6mL of o-dichlorobenzene, then add 15mL of diphenyl ether and 0.2mL of oleylamine into the solution ﹑Use 0.2mL of oleic acid and 43mg of 1,2-tetradecanediol to obtain a mixed solution;

[0036] (2) Stir and heat the mixed solution obtained in step (1) to 160°C and keep it warm for 30 minutes, then raise the temperature to 230°C, add 126.8 mg of activated carbon powder when the solution starts to turn brown, and keep it warm for 1 hour;

[0037] (3) Cool the reaction product after heat preservation in step (2) to 23°C, then add 20mL cyclohexane and 10mL absolute ethanol to the reaction product, the volume ratio of cyclohexane and absolute ethanol is 2:1, and ultrasonically Suction filtration and separation after uniform dispersion to ob...

Embodiment 2

[0041] Embodiment 2: the preparation method of this carbon-supported platinum-cobalt nano-alloy catalyst, concrete operation is as follows:

[0042] The preparation method of the carbon-supported platinum-cobalt nano-alloy catalyst in this example is the same as in Example 1, except that the holding time in step (5) is 4 hours.

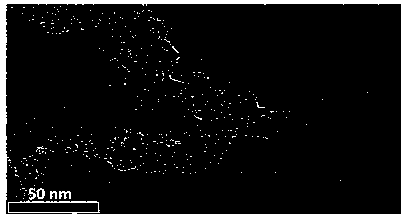

[0043] figure 2 The TEM figure of the carbon-supported platinum-cobalt nano-alloy catalyst prepared for the present embodiment, figure 2 Show Pt 3 The Co alloy has been supported on carbon and has good dispersion.

Embodiment 3

[0044] Embodiment 3: the preparation method of this carbon-supported platinum-cobalt nano-alloy catalyst, concrete operation is as follows:

[0045] The preparation method of the carbon-supported platinum-cobalt nano-alloy catalyst in this example is the same as in Example 1, except that the holding time in step (5) is 6 hours.

[0046] image 3 The TEM figure of the carbon-supported platinum-cobalt nano-alloy catalyst prepared for the present embodiment, image 3 It shows that the nanoparticles are mainly distributed between 1.00 ~ 3.00nm, compared with Example 1 and Example 2, it shows that the further increase of the holding time, the size of the nanoparticles is smaller.

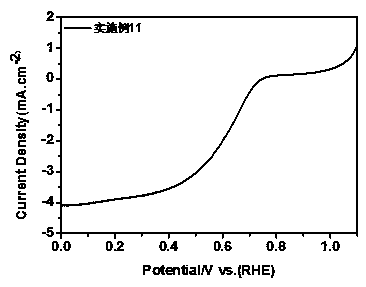

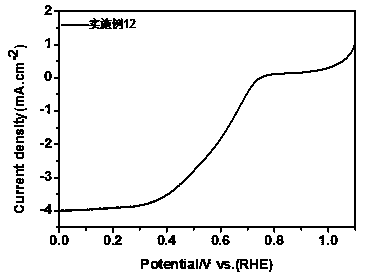

[0047] Figure 4 It is the Pt synthesized by Examples 1, 2, and 3 of the present invention 3 Co / C nanoalloy catalyst in 0.1M HClO 4 Solution O 2 Comparison of LSV curves in atmosphere, Figure 4 Indicates that the holding time has a significant effect on Pt 3 The Co / C nano-alloy catalyst has an in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| half wave potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com