Method for constructing monatomic catalyst based on lignin/metal supramolecular assembly

A technology of lignin and catalyst, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of high raw material cost, poor universality, complex process, etc., achieve low cost and increase space The effect of distance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the synthesis of metal single atom catalyst precursor

[0021] 1) Dissolve 8g of lignin in 1L of deionized water to form solution A. Zinc nitrate hexahydrate (11.90g, 40mmol Zn 2+ ) and cobalt nitrate hexahydrate (2.33g, 8mmol Co 2+ ) was dissolved in 0.5L deionized water to prepare solution B.

[0022] 2) Add solution B to solution A, mix quickly with mechanical stirring, the pH is natural (pH ~ 6.1), the mixture continues to stir for 1 hour, and then stands overnight at room temperature.

[0023] 3) Pour off the supernatant, centrifuge at 5,000×g for 10 minutes, and dry the precipitate at 80°C overnight to obtain a metallic cobalt single-atom catalyst precursor, named Co 1 Zn 5 -L.

[0024] 4) Similarly, by replacing metal cobalt with other metal ions, such as iron, nickel, copper, manganese, zirconium, molybdenum, etc., a lignin / metal supramolecular assembly was obtained, named M 1 Zn 5 -L(M represents a metal ion, such as Fe 3+ , Ni 2+ ,Cu 2+...

Embodiment 2

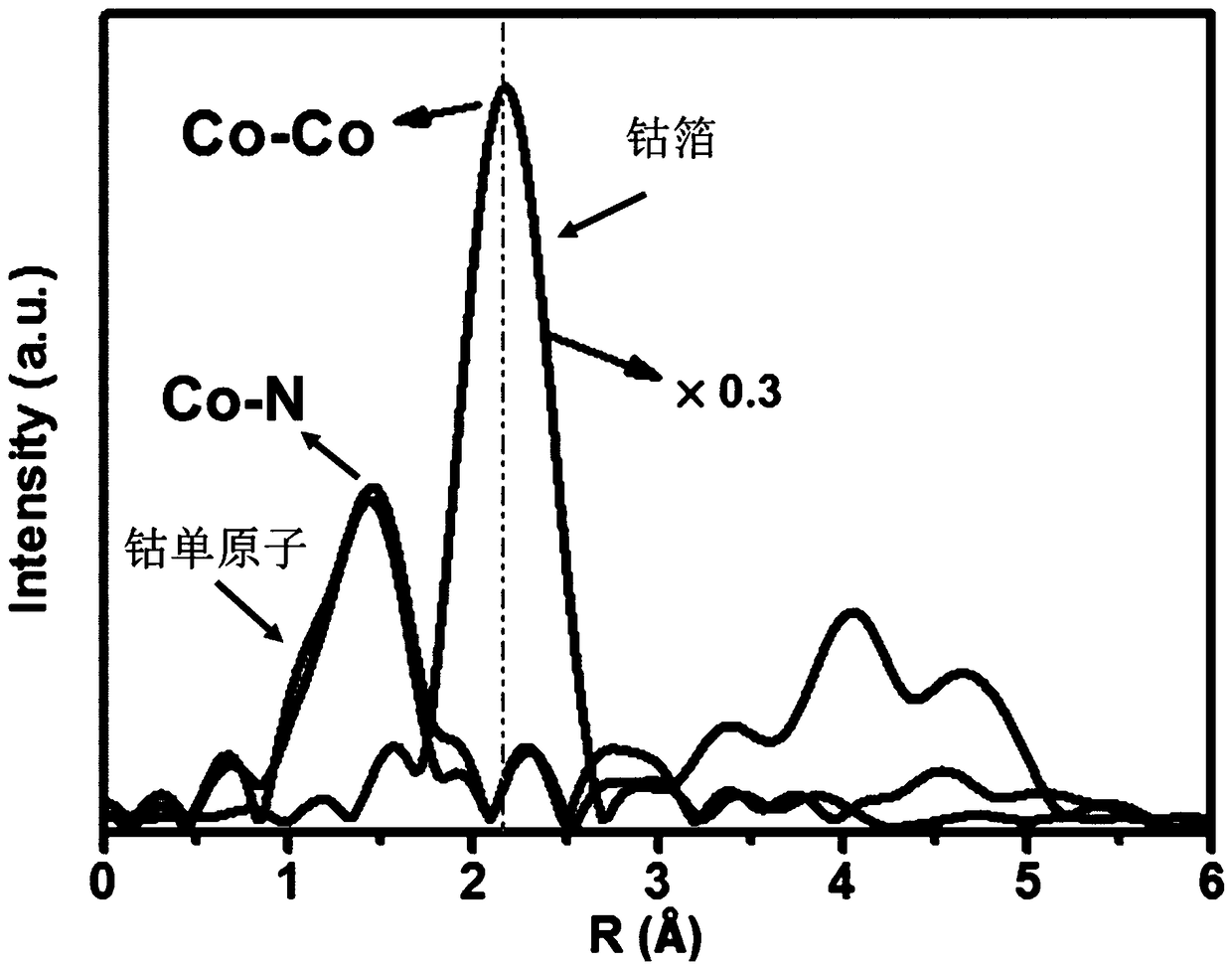

[0029] Embodiment 2: the synthesis of metal single atom catalyst

[0030] 1) Take 0.1g lignin / metal cobalt catalyst precursor Co 1 Zn 5 -L and 1g of dicyandiamide, thoroughly grind and mix.

[0031] 2) Put the ground powder into a porcelain boat and put it in a tube furnace with an argon flow rate of 75mL / min. The temperature was raised to 900°C / min, and then naturally cooled to room temperature after holding for 3 hours to obtain a nitrogen-doped carbon-supported cobalt single-atom catalyst.

[0032] 3) Similarly, the lignin / metal supramolecular assembly of lignin / metal supramolecular assembly M 1 Zn 5 -L(M represents a metal ion, such as Fe 3+ , Ni 2+ ,Cu 2+ ,Mn 2+ , Zr 2+ ,Mo 2+ ; L represents lignin), and 1g of dicyandiamide, fully ground and mixed. The mass ratio of metal precursor to dicyandiamide is 1:10, the temperature is programmed to 900°C, and sintered at high temperature to obtain a nitrogen-doped carbon-supported metal single-atom catalyst.

[0033] 4...

Embodiment 3

[0035] Example 3: Activity Evaluation of Metal Single Atom Catalysts

[0036] 1) Add 10mL of methanol, 1mmol of benzyl alcohol and 2.5mol% metal cobalt single-atom catalyst into a 100mL round bottom flask, and 0.25mmol of anisole as an internal standard.

[0037] 2) Replace the air in the round-bottomed flask with pure oxygen earlier, at 1bar O 2 (Oxygen balloon), react under the condition of 60 DEG C, take samples regularly, and analyze the reaction product by HPLC. The analysis conditions are: chromatographic column C18, column temperature 30°C, mobile phase 30% acetonitrile and 70% water (containing 0.05v% trifluoroacetic acid), flow rate 1mL / min, UV detector 254nm.

[0038] 3) The catalyst is replaced with other metal single-atom catalysts (such as iron, nickel, copper, manganese, zirconium, molybdenum, etc.) to catalyze the oxidative esterification of benzyl alcohol and methanol to prepare methyl benzoate, and the reaction system and product detection conditions remain u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com