Zinc oxide varistor with aluminum electrode and preparation method thereof

A varistor, aluminum electrode technology, applied in the direction of varistor core, varistor, and resistors with terminals, etc., can solve the complex process, low production efficiency, insufficient activity of aluminum welding flux, etc. problem, to achieve the effect of simple preparation process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

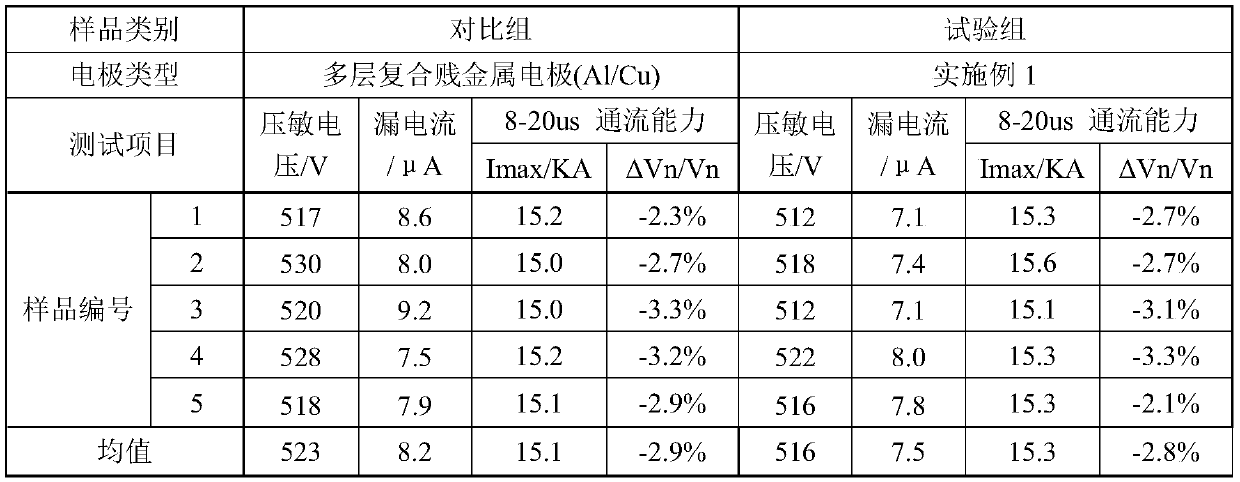

Embodiment 1

[0045] In this embodiment, a zinc oxide varistor with aluminum electrodes includes a ZnO ceramic substrate, electrodes, and electrode lead wires. The ZnO ceramic substrate has a sheet structure. Electrodes are provided on both sides of the ZnO ceramic substrate. Connect with the electrode lead-out line; the electrode is an aluminum electrode. The shape of the ZnO ceramic substrate is circular, the diameter is 20mm, and the voltage level is 320V; the shape of the sprayed Al electrode is the same as the ceramic substrate, and it is also circular, but the diameter of the aluminum electrode is slightly smaller than the diameter of the ceramic surface; the electrode lead is Copper wire, 0.8mm in diameter, soldering solder is Sn-Ag-Ti solder.

[0046] The specific preparation process of the zinc oxide varistor with aluminum electrode is as follows:

[0047] a. Surface pretreatment. Perform surface pretreatment on the ZnO ceramic substrate to be sprayed to remove impurities such as powd...

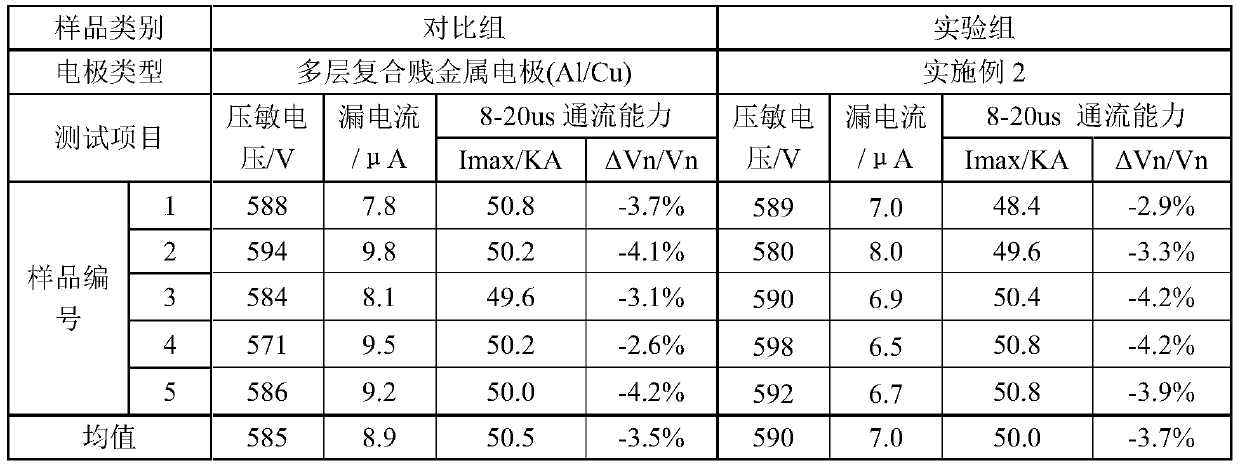

Embodiment 2

[0063] In this embodiment, a zinc oxide varistor with aluminum electrodes includes a ZnO ceramic substrate, electrodes, and electrode lead wires. The ZnO ceramic substrate has a sheet structure. Electrodes are provided on both sides of the ZnO ceramic substrate. Connect with the electrode lead-out line; the electrode is an aluminum electrode. The ZnO ceramic substrate is a square zinc oxide varistor with a specification of V34E350. The difference between this embodiment and the first embodiment is: the ZnO ceramic substrate is square, the side length is 34mm, and the voltage level is 350V; the electrode shape is the same as the electronic ceramic substrate shape , Also square; electrode lead wire is tin-plated copper pin; soldering solder is Sn-Ag-Ti-Ce solder.

[0064] The specific preparation process of the zinc oxide varistor with aluminum electrode is as follows:

[0065] a. Surface pretreatment. Perform surface pretreatment of the ZnO ceramic substrate to be sprayed to remov...

Embodiment 3

[0081] In this embodiment, a zinc oxide varistor with aluminum electrodes includes a ZnO ceramic substrate, electrodes, and electrode lead wires. The ZnO ceramic substrate has a sheet structure. Electrodes are provided on both sides of the ZnO ceramic substrate. Connect with the electrode lead-out line; the electrode is an aluminum electrode. The ZnO ceramic substrate is a square zinc oxide varistor with a specification of V34E150. The difference between this embodiment and Example 1 and Example 2 is that the ZnO ceramic substrate is square, with a side length of 34mm, and a voltage level of 150V; electrode shape and electronics The ceramic substrate has the same shape and is also square; the electrode leads are tin-plated copper-clad steel pins; the soldering solder is Sn-Ag-Ti solder.

[0082] The specific preparation process of the zinc oxide varistor with aluminum electrode is as follows:

[0083] a. Surface pretreatment. Perform surface pretreatment of the ZnO ceramic substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com