A kind of preparation method of white graphene composite resin hardening liquid and PET hardening layer

A technology of white graphene and composite resin, applied in coatings, conductive coatings, polyurea/polyurethane coatings, etc., can solve the problems of hardened layer not wear-resistant, easy to crack, and electrical function failure, so as to prevent agglomeration, Avoid the deterioration of processing performance and enhance the effect of interface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

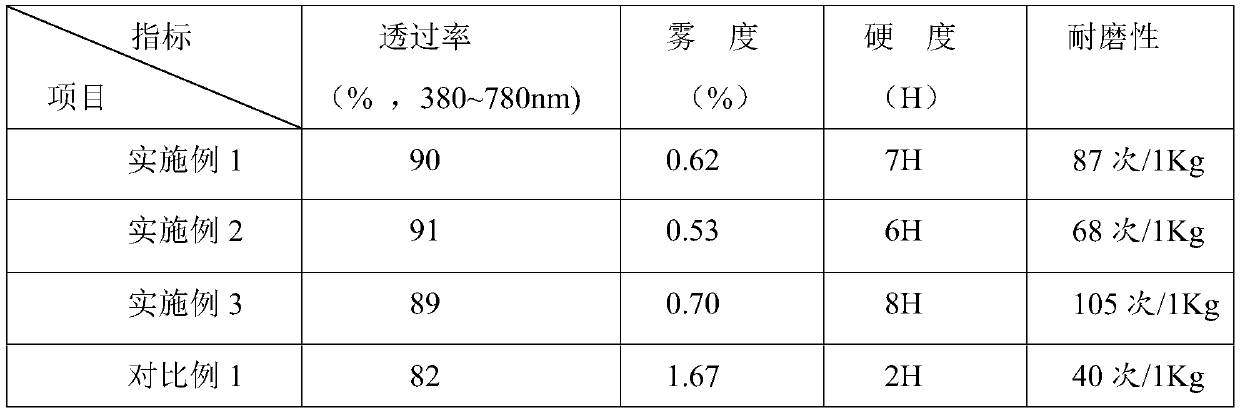

Examples

Embodiment 1

[0044] White Graphene Modification

[0045] Take 2-10 layers of 10g white graphene powder and add it to a round bottom flask, and add 100ml of distilled water to the round bottom flask, then ultrasonically disperse, add 0.2g sodium dodecyl sulfate to the round bottom flask, and stir at high speed ultrasonically , to obtain lipophilic modified white graphene; acrylic acid is subjected to vacuum distillation in advance;

[0046] After heating the above-mentioned lipophilic modified modified white graphene dispersion to 85°C, add 1g of ammonium persulfate initiator, stir for 10min, start to add 1g of acrylic acid dropwise, and finish dropping in 0.5h. After the dropwise addition, keep warm for 30 min until the reaction is complete. After the reaction is completed, adjust the pH value to 7 with ammonia water, quickly cool to room temperature, filter under reduced pressure, wash the filter cake with distilled water for 3 times, and then wash with alcohol once, and vacuum dry and ...

Embodiment 2

[0052] White Graphene Modification

[0053] Take 10g of white graphene powder with 5-10 layers and add it to a round bottom flask, and add 100ml of ethanol to the round bottom flask, then ultrasonically disperse, add 0.5 parts of oleic acid to the round bottom flask, and ultrasonically stir at high speed to obtain lipophilic Modified white graphene: After heating the above-mentioned oleophilic modified white graphene dispersion to 85°C, add 1 part of ammonium persulfate initiator, stir for 10 minutes, start to add 1 g of methyl acrylate dropwise, and finish dropping in 0.5 hours. After the dropwise addition, keep warm for 45 minutes until the reaction is complete. After the reaction is completed, adjust the pH value to 7 with ammonia water, quickly cool to room temperature, filter under reduced pressure, wash the filter cake with distilled water for 4 times, wash with alcohol once, and vacuum dry at 70°C, grind to obtain methyl acrylate-coated modified Modified white graphen...

Embodiment 3

[0059] White Graphene Modification

[0060] Take 2-5 layers of 15g white graphene powder and add it to a round bottom flask, and add 100ml distilled water to the round bottom flask, then ultrasonically disperse, add 0.5g oleylamine to the round bottom flask, and ultrasonically stir at high speed to obtain lipophilic Modified white graphene: After heating the above-mentioned oleophilic modified white graphene dispersion to 90°C, add 1g of initiator azobisisobutyronitrile, stir for 10min, start to add 1g of ethyl acrylate dropwise, and finish dropping in 1h . After the dropwise addition, keep warm for 30 min until the reaction is complete. After the reaction, use ammonia water to adjust the pH value to 7, quickly cool to room temperature, filter under reduced pressure, wash the filter cake with distilled water for 3 times, wash with alcohol once, and vacuum dry at 80°C, grind to obtain ethyl acrylate coated modified white graphene;

[0061] Preparation of white graphene co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com