A kind of metal mold environmental protection coating for carbon-iron alloy casting and preparation process thereof

An environmentally friendly coating and ferroalloy technology, applied in the field of coatings, can solve the problems of loss, easy cracking or deformation, serious loss of ingot molds, etc., and achieve the effect of long duration and avoiding strong thermal shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

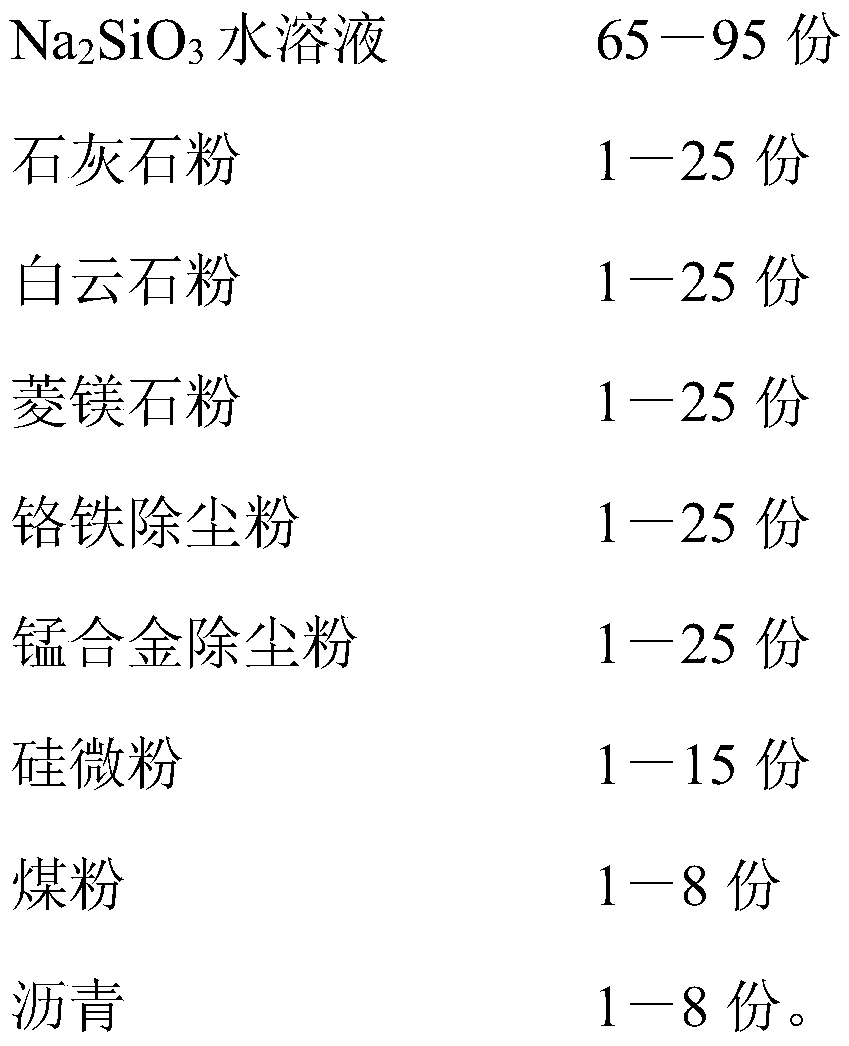

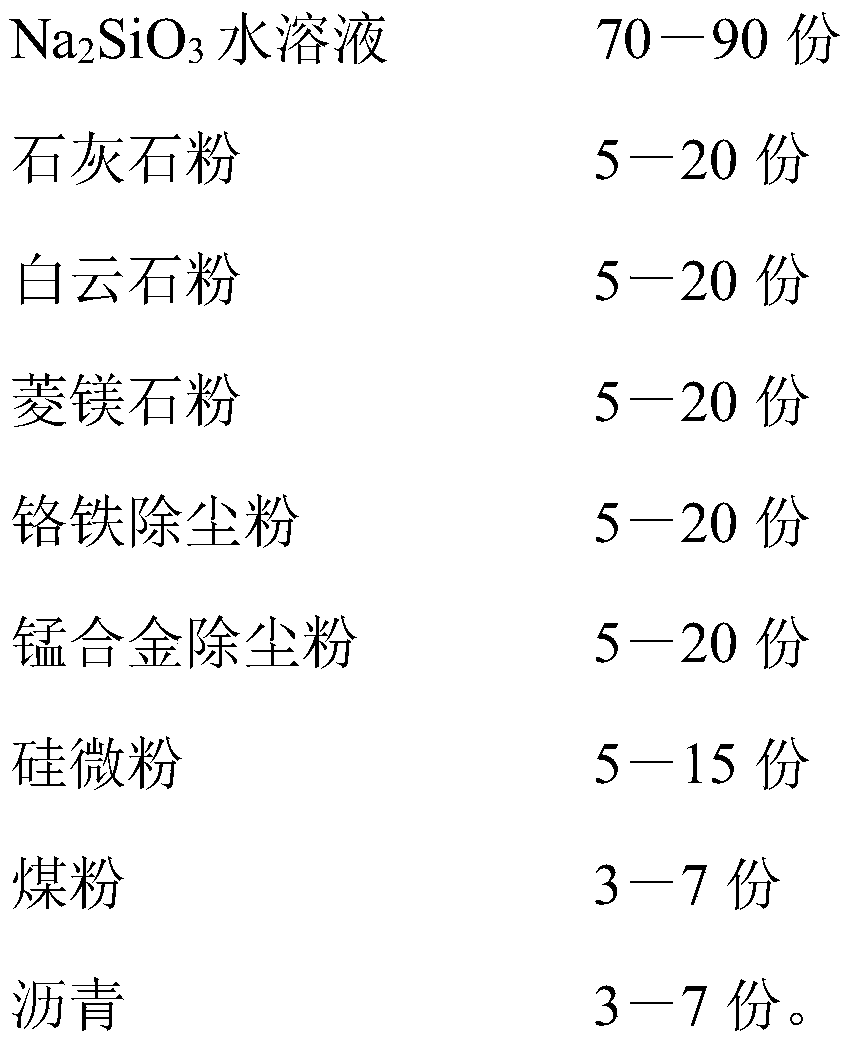

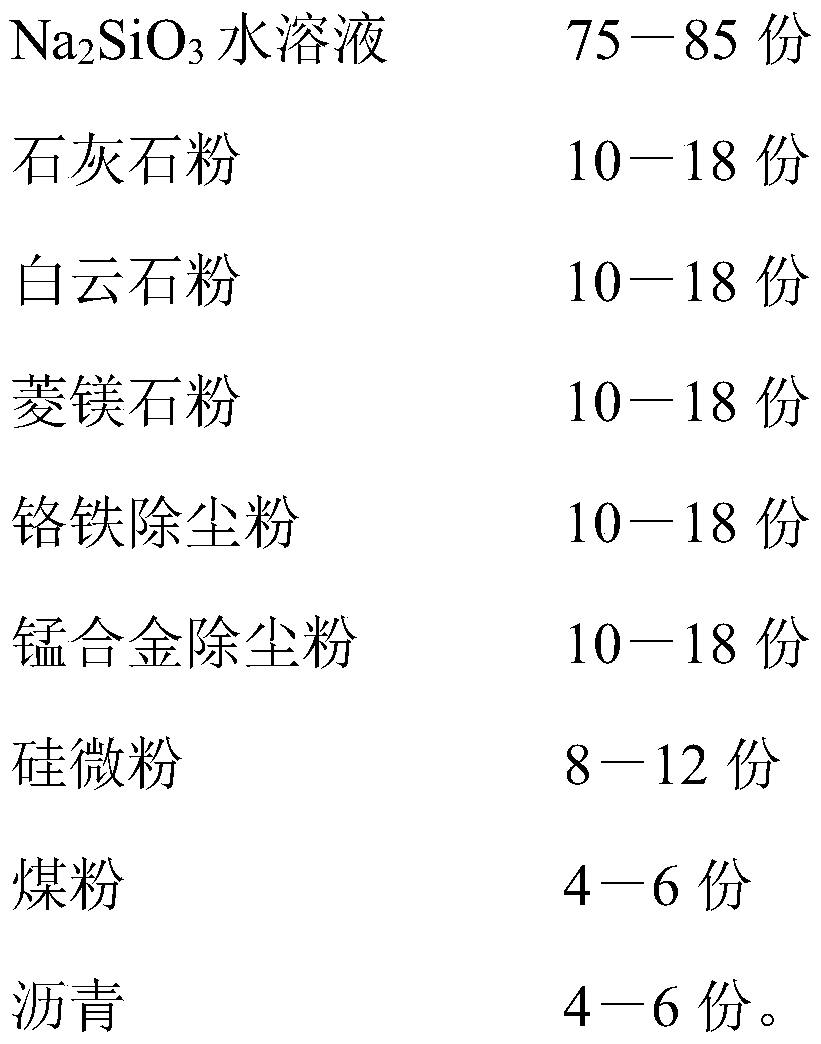

Method used

Image

Examples

Embodiment 1

[0053] The carbon iron alloy cast metal mold environmental protection coating based on oxidation-reduction reaction of the present embodiment, and preparation technology thereof, it comprises the following processing steps:

[0054] 1), grinding 20 parts of dolomite powder into powder respectively, the fineness of the powder is not less than 200 mesh;

[0055] 2), use pure water to mix 70 parts of Na with a modulus of 1.5-3.5 2 SiO 3 The aqueous solution is diluted to 10%-80% Na 2 SiO 3 Aqueous solution, join in the reactor, start the stirrer and stir for 5min;

[0056] 3), slowly add 20 parts of dolomite powder ground into powder in step 1), and 5 parts of manganese oxide, 3 parts of silicon micropowder, and 2 parts of coal powder into the reactor, continue to start the mixer, and stir for 4 hours to obtain an environmentally friendly coating;

[0057] 4) Inspection: The density of the prepared environmentally friendly coating is in the range of 1.05-2.0, which is a qual...

Embodiment 2

[0060] The carbon iron alloy cast metal mold environmental protection coating based on oxidation-reduction reaction of the present embodiment, and preparation technology thereof, it comprises the following processing steps:

[0061] 1), 10 parts of limestone powder and 10 parts of dolomite powder are respectively ground into powder, and the fineness of powder is not less than 200 mesh;

[0062] 2), use pure water to mix 60 parts of Na with a modulus of 1.5-3.5 2 SiO 3 The aqueous solution is diluted to 10%-80% Na 2 SiO 3 Aqueous solution, join in the reactor, start stirrer and stir 4min;

[0063] 3), 10 parts of limestone powder and 10 parts of dolomite powder that are ground into powder in step 1), and 3 parts of magnesite powder, 2 parts of ferrochrome dust removal powder, 6 parts of high carbon ferromanganese alloy dust removal powder, 5 parts of silicon micropowder, Slowly add 3 parts of coal powder and 1 part of asphalt powder into the reactor, continue to start the m...

Embodiment 3

[0067] The carbon iron alloy cast metal mold environmental protection coating based on oxidation-reduction reaction of the present embodiment, and preparation technology thereof, it comprises the following processing steps:

[0068] 1), 8 parts of limestone powder and 7 parts of dolomite powder are ground into powder respectively, and the fineness of powder is not less than 200 mesh;

[0069] 2), use pure water to mix 75 parts of Na with a modulus of 1.5-3.5 2 SiO 3 The aqueous solution is diluted to 10%-80% Na 2 SiO 3 Aqueous solution, join in the reactor, start the stirrer and stir for 6min;

[0070] 3), 8 parts of limestone powders and 2 parts of dolomite powders that are ground into powder in step 1), and 4 parts of magnesite powders, 3 parts of ferrochrome dust removal powders, 4 parts of manganese silicon alloy dust removal powders, 2 parts of silicon micropowder, 1 Slowly add one part of coal powder and one part of asphalt powder into the reactor, continue to start ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com