Manufacturing technology for circular saw blade of metal ceramic cold saw

A cermet and manufacturing process technology, applied in manufacturing tools, metal sawing equipment, metal processing equipment and other directions, can solve the problems of high requirements for cold sawing process conditions, long inspection and leveling time, and high manufacturing costs, so as to improve process production. The effect of high efficiency, high stress detection accuracy and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

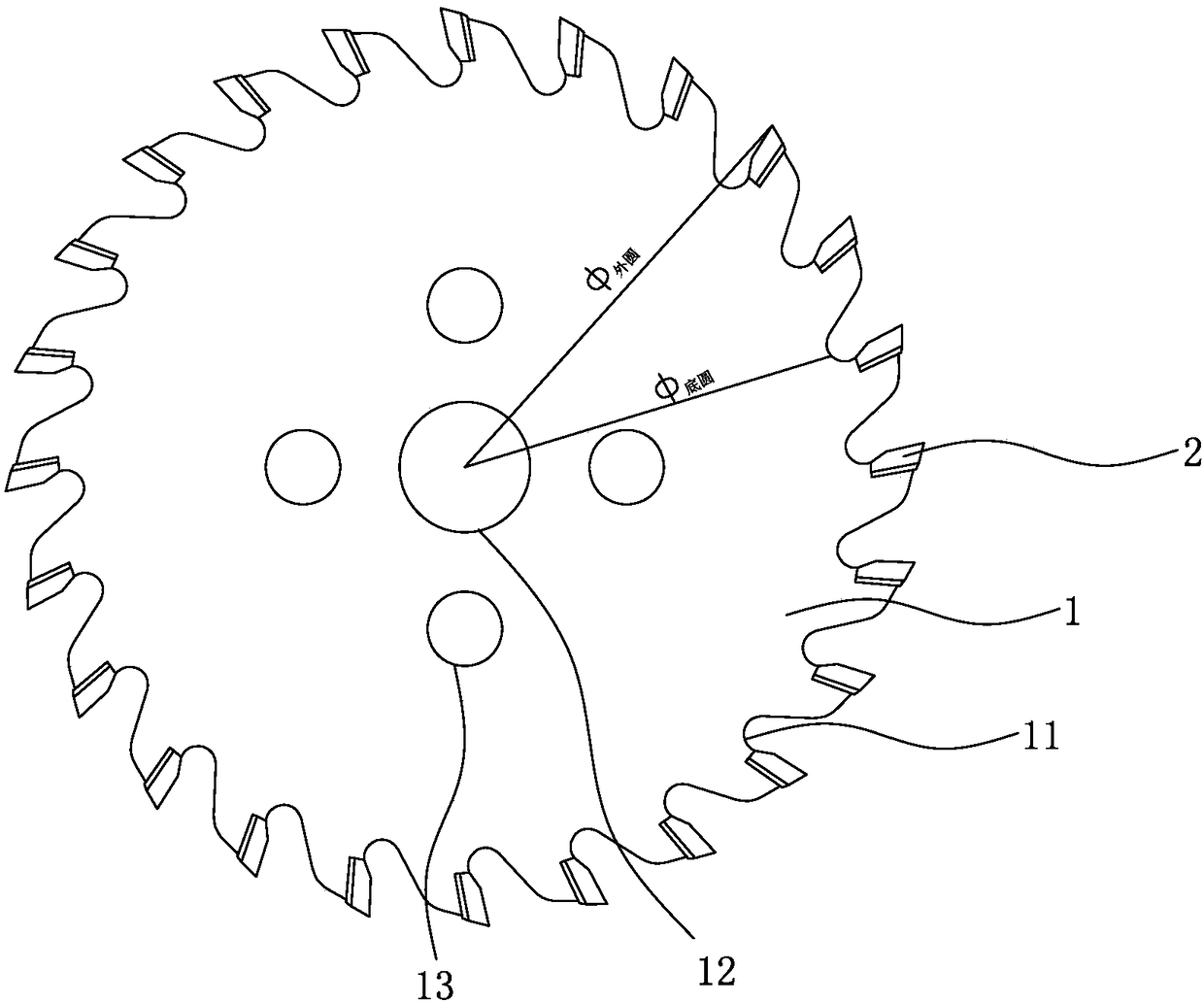

[0040] Such as Figure 1 to Figure 10 As shown, the cermet cold saw circular saw blade includes a circular blade body 1 and a blade 2 arranged on the blade body 1, and the blade 2 is made of Ti(C,N) added with WC, Mo2C, NbC, TaC, Co and Ni metal Made of ceramics, the sheet 1 is made of 8CrV or 8CrNi2 plate. During the material selection process of the plate, magnetic flaw detection is used to ensure that the plate is of high quality and flawless, and the hardness of the plate 1 must be tested.

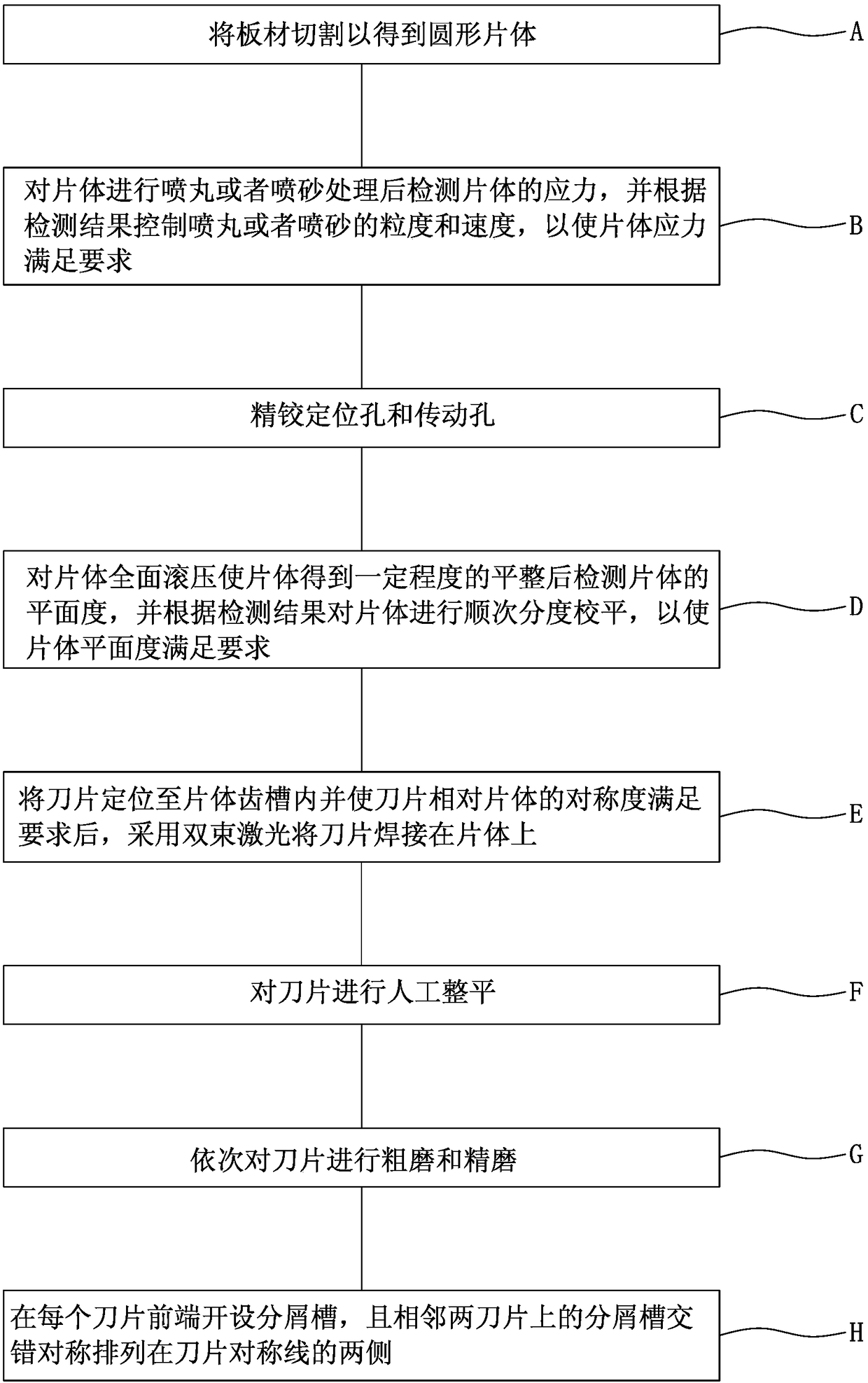

[0041] The manufacturing process of metal-ceramic cold saw circular saw blades includes the following steps:

[0042] A. Use a high-precision CNC laser cutting machine to cut the plate to obtain a circular sheet 1 with a plurality of circumferentially distributed tooth grooves 11 on the outer periphery. The sheet 1 is provided with a central positioning hole 12 and surrounding positioning holes 12 Four transmission holes 13 distributed around the circumference, the distance from the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com