Automatic welding wire filling and conveying device

A welding wire, automatic technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of affecting welding quality and efficiency, lack of feel when holding the welding wire, unable to hold the welding wire continuously and stably, and improve welding quality. With the effect of efficiency, convenient and quick push

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the implementations shown in the drawings, but it should be noted that these implementations are not limitations of the present invention, and those of ordinary skill in the art based on the functions, methods, or structural changes made by these implementations Equivalent transformations or substitutions all fall within the protection scope of the present invention.

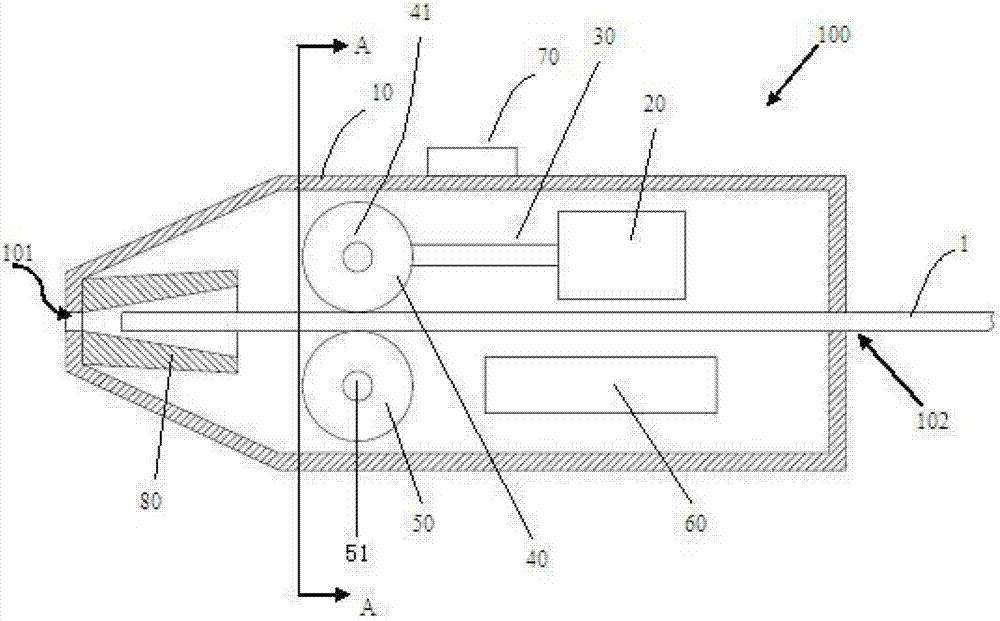

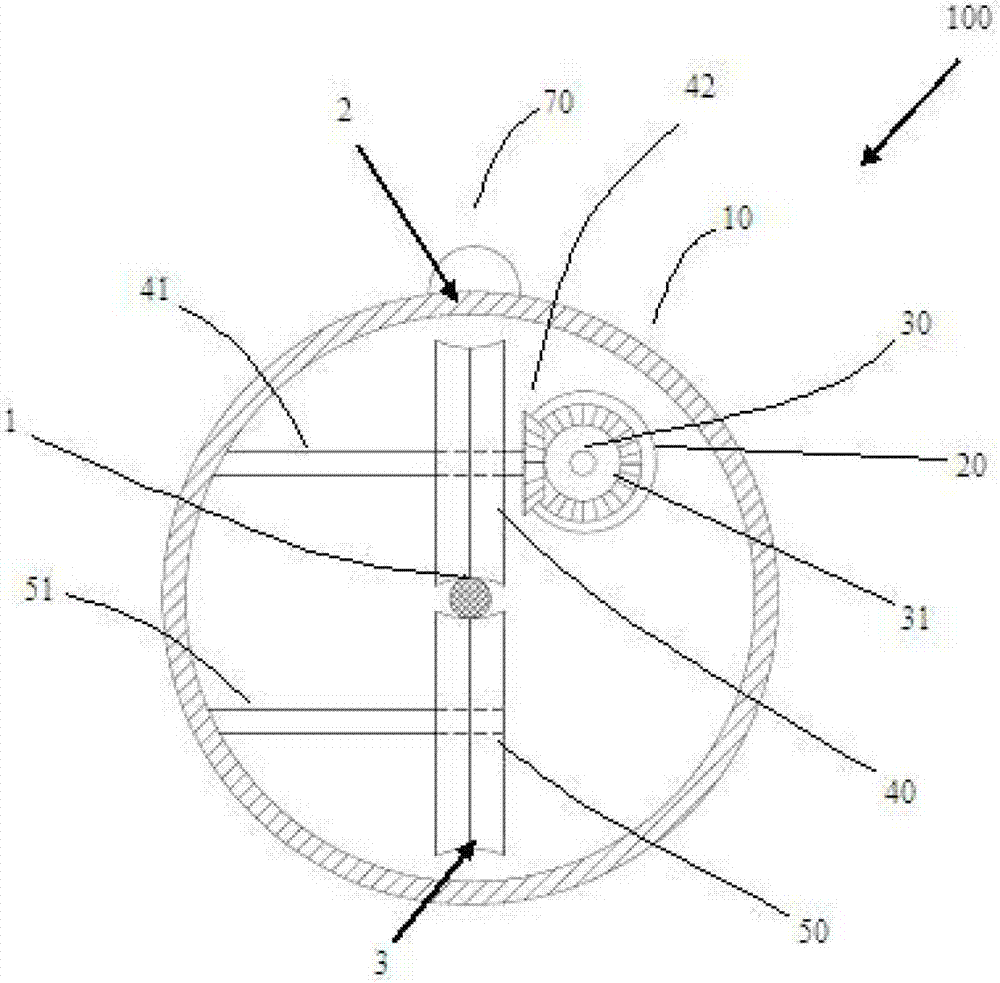

[0018] Please refer to figure 1 as shown, figure 1 It is a structural schematic diagram of a specific embodiment of a welding wire automatic feeding device of the present invention. In this embodiment, an automatic welding wire feeding device 100 includes: a housing 10 provided with a welding wire inlet 102 and a welding wire outlet 101 . And the driving mechanism 20 , the transmission mechanism 30 , the driving guide wheel 40 , the driven guide wheel 50 and the power supply 60 arranged inside the casing 10 . And a button 70 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com