All-position MAG mechanical welding process and application of pipeline fixing port

A technology for pipe fixing and welding process, applied in the application, welding medium, welding equipment and other directions, can solve the problems of high construction cost, heavy maintenance workload, complex submerged arc welding equipment, etc., to improve welding quality and efficiency, welding High first pass rate, stable and reliable welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

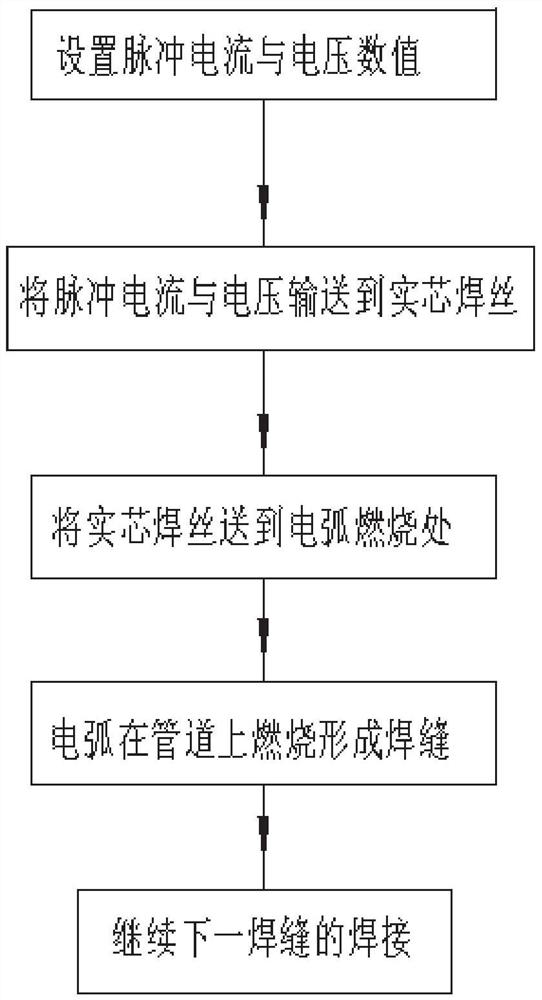

[0027] Such as figure 1 As shown, the present embodiment provides a kind of all-position MAG mobile welding welding process for the fixed opening of the pipeline, including the following steps:

[0028] Step 1, set the output welding pulse current and voltage values on the welding power source;

[0029] Step 2, delivering the pulsed current and voltage to the solid welding wire;

[0030] Step 3, the solid cored wire sends the solid cored wire on the solid cored wire reel to the arc burning place through the wire feeding roller;

[0031] Step 4, the arc burns on the pipeline to form a weld;

[0032] Step 5, continue the welding of the next weld seam.

[0033] In step 2, the power supply voltage output by the welding power supply is 18-20V. In step 3, the groove of the welding part of the pipeline is a double V-shaped groove, and the groove angle is 56-80°. The welding material of the solid wire is suitable for the material of the pipe to be welded, and the diameter of th...

Embodiment 2

[0035] This embodiment provides an application of the all-position MAG motorized welding process of the fixed port of the pipeline in the welding of A106Gr.B pipelines. The specific welding steps are the same as those in Example 1, and the differences are as follows:

[0036] In step 1, the pulse current is 140-150A, and the voltage is 18-20V.

[0037] During the welding process, the welding current actually refers to the wire feeding speed. The size of the welding current depends on the speed of the wire feeding. If the welding current is too large, the line energy will burn the alloy components in the welding material too much, so that the weld Overall performance deteriorates. During the filling process of the hot solder layer, it is easy to penetrate the bottom weld seam, the weld seam will be oxidized, and the large splash will block the end of the contact tip, and the molten pool will become larger and the liquid metal will increase. The molten pool is difficult to contr...

Embodiment 3

[0054] This embodiment provides an application of the all-position MAG motorized welding process of the fixed port of the pipeline in the welding of heat-resistant steel 335-P11 and 335-P11 pipelines. The specific welding steps are the same as those in Example 1, and the differences are as follows:

[0055] In step 1, the pulse current is 130-140A, and the voltage is 18-20V.

[0056] During the welding process, the welding current actually refers to the wire feeding speed. The size of the welding current depends on the speed of the wire feeding. If the welding current is too large, the line energy will burn the alloy components in the welding material too much, so that the weld Overall performance deteriorates. During the filling process of the hot solder layer, it is easy to penetrate the bottom weld seam, the weld seam will be oxidized, and the large splash will block the end of the contact tip, and the molten pool will become larger and the liquid metal will increase. The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Dry elongation | aaaaa | aaaaa |

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com