Thick steel plate double-sided laser-MAG composite large root face backing welding method

A hybrid welding and laser technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as air holes, and achieve the effect of improving welding quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Taking the SA-738Gr.B steel butt horizontal welding process with a length of 500mm and a plate thickness of 80mm as an example, the welding implementation steps and process are described in detail.

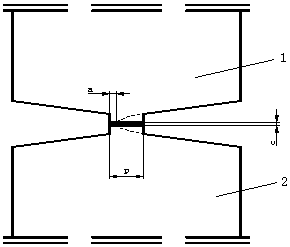

[0020] (1) Machining the first workpiece to be welded 1 and the second workpiece 2 to be welded into double U-shaped welding grooves with blunt edges, the thickness p of the blunt edges without penetration is 7mm;

[0021] (2) Assemble the first workpiece to be welded and the second workpiece to be welded, the assembly gap c is 0~0.3mm;

[0022] (3) Remove oxide scale, oil stains, rust, moisture and other dirt from the groove and its surroundings before welding;

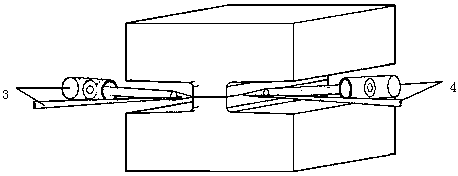

[0023] (4) The front laser-MAG composite welding gun 3 and the rear laser-MAG composite welding gun 4 are used for bottom welding with φ1.2mm welding wire on both sides of the welding groove. The front laser-MAG composite welding gun starts arcing at an interval of 8s, and the rear laser- MAG composite welding torch start...

Embodiment 2

[0025] Taking the A514Gr.Q steel butt horizontal welding process with a length of 500mm and a plate thickness of 114mm as an example, the welding implementation steps and processes are described in detail.

[0026] (1) Machining the first workpiece to be welded and the second workpiece to be welded into double V-shaped welding grooves with blunt edges, the thickness p of the blunt edges without penetration is 9mm;

[0027] (2) Assemble the first workpiece to be welded and the second workpiece to be welded, and the assembly gap c is 0~0.2mm;

[0028] (3) Remove oxide scale, oil stains, rust, water and other dirt from the groove and its surroundings before welding;

[0029] (4) Use the front laser-MAG composite welding torch and the rear laser-MAG composite welding torch to use φ1.2mm welding wire for bottom welding on both sides of the welding groove. The front laser-MAG composite welding torch starts arcing at an interval of 30s, and the rear laser-MAG composite welding torch The weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com