Polymer-based dielectric composite material of silica-coated calcium copper titanate nanofiber, and preparation method thereof

A technology of copper calcium titanate and nanofibers, which is applied in fiber processing, artificial filaments of inorganic materials, textiles and papermaking, etc., can solve problems such as high dielectric loss, achieve dielectric loss suppression, improve dielectric properties, and The effect of increasing the electrical constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

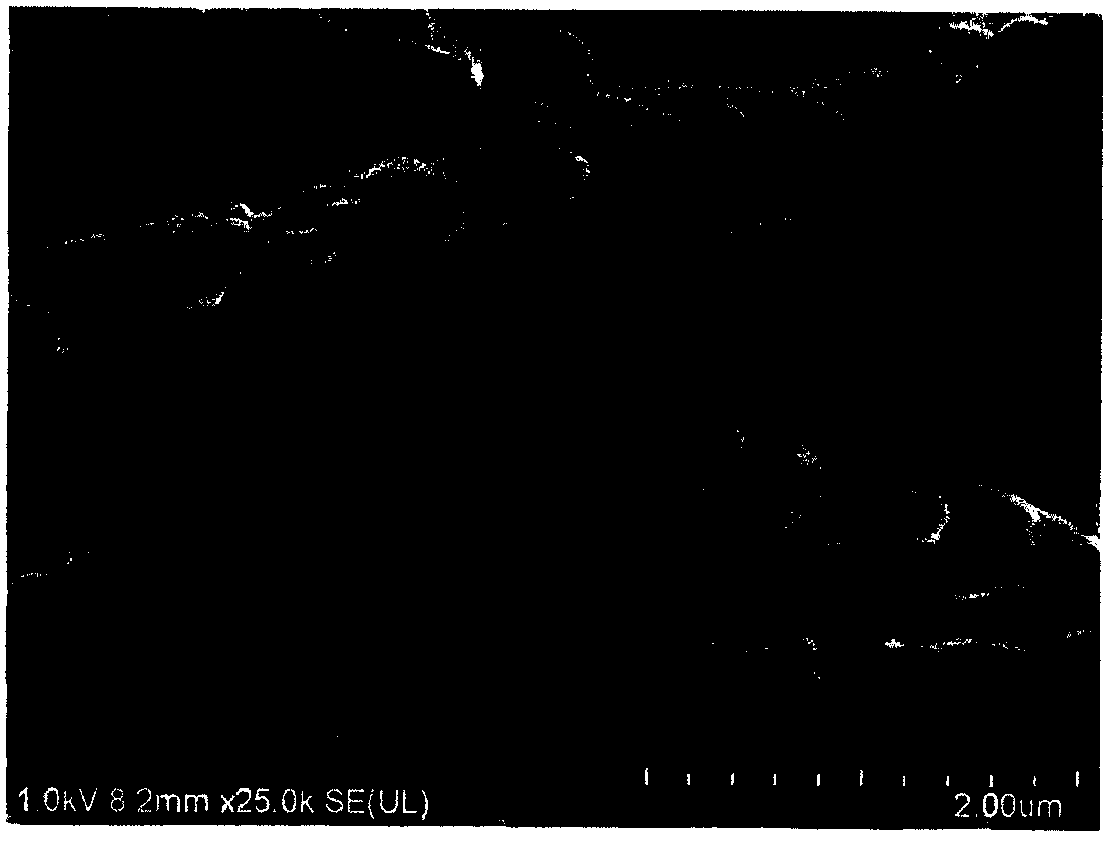

[0008] Example 1 Preparation of copper calcium titanate nanofibers by electrospinning

[0009] (1) Calcium nitrate, copper acetate, and tetrabutyl titanate are configured into a solution according to a molar ratio of 1:3:4, and the solvent is acetic acid and ethanol (volume ratio 1:1). After stirring and dissolving, polyvinylpyrrolidone is added, Continue stirring for 1 hour;

[0010] (2) Put the above solution into a syringe, and carry out electrospinning under the impetus of a propulsion pump. The spinning voltage range is 19 kV, and aluminum foil is used as a receiver;

[0011] (3) After the spinning is finished, remove the fiber from the aluminum foil and put it into a crucible, and sinter it in a muffle furnace under an air atmosphere at a temperature range of 800 degrees Celsius to finally obtain copper calcium titanate nanofibers.

Embodiment 2

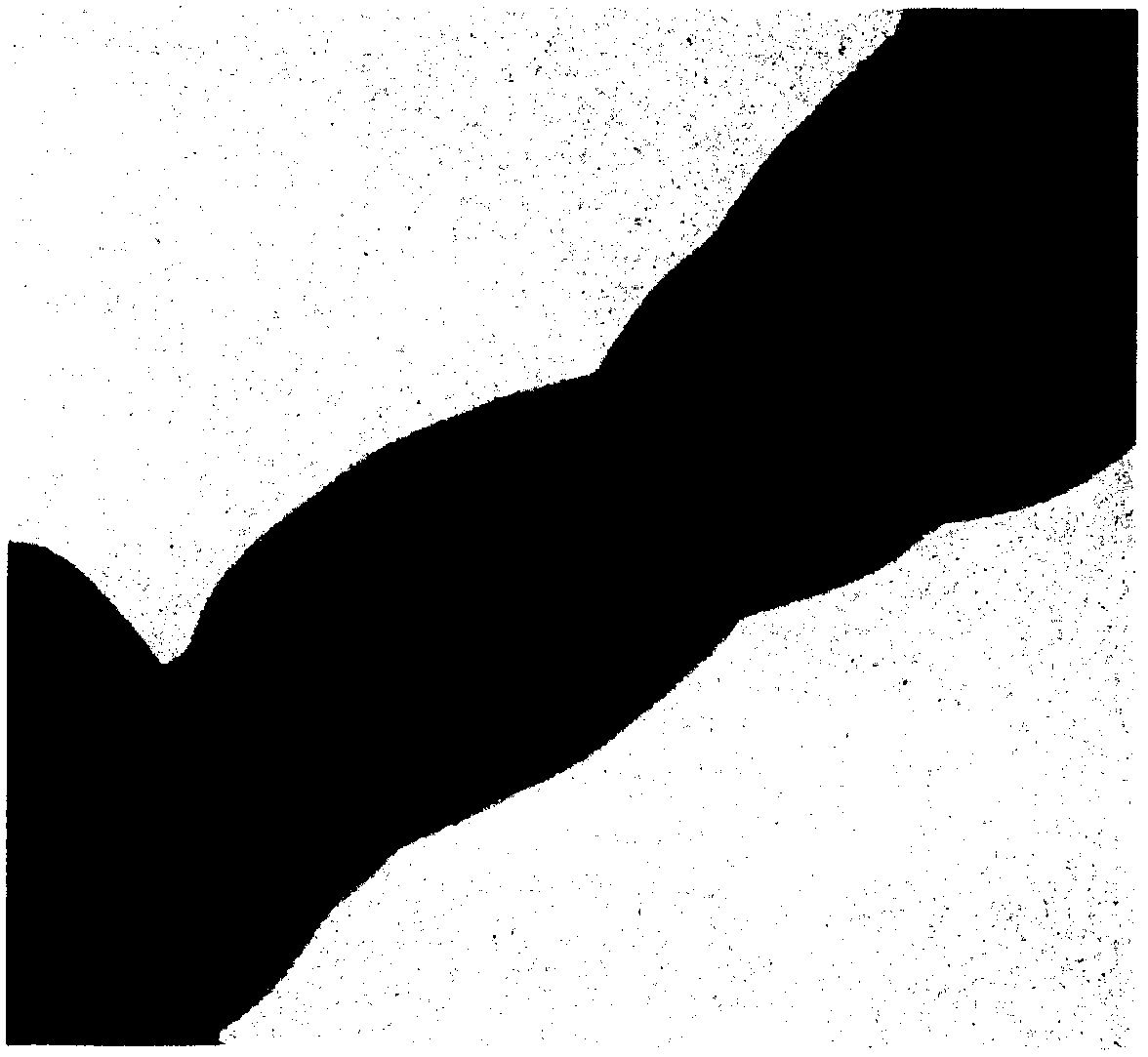

[0012] Example 2 Preparation of silica-coated copper calcium titanate nanofibers by hydrolysis of tetraethyl orthosilicate

[0013] (1) Place 1 gram of copper calcium titanate nanofibers prepared in Example 1 in a mixed solvent of ethanol-water, the volume ratio of water and ethanol in the mixed solvent is 1:2, and ultrasonically treat for 1 h under mechanical stirring .

[0014] (2) In the above solution, under strong mechanical stirring, slowly add 2 ml of tetraethyl orthosilicate dropwise, after continuous stirring for 30 minutes, slowly add 2 ml of ammonia water dropwise, and continue stirring for 2 hours.

[0015] (3) Transfer the above solution into a centrifuge tube, and centrifuge at a speed of 3000 rpm for 30 minutes, discard the supernatant, and dry the lower part of the precipitate at a drying temperature of 70 degrees Celsius and a drying time of 12 hours , and finally obtain silica-coated copper calcium titanate nanofibers.

Embodiment 3

[0016] Example 3 Preparation of polyvinylidene fluoride composite film by solution casting method

[0017] (1) Uniformly disperse 0.12 g of the silica-coated copper calcium titanate nanofibers prepared in Example 2 in 9 g of N,N-dimethylformamide, and ultrasonicate for 1 hour.

[0018] (2) Add 1 gram of polyvinylidene fluoride powder to the above solution, and keep stirring for 12 hours.

[0019] (3) The above solution was poured on a clean and flat glass plate, cast to form a film, and dried at 70 degrees Celsius for 12 hours to obtain a polyvinylidene fluoride composite film of silica-coated copper calcium titanate nanofibers.

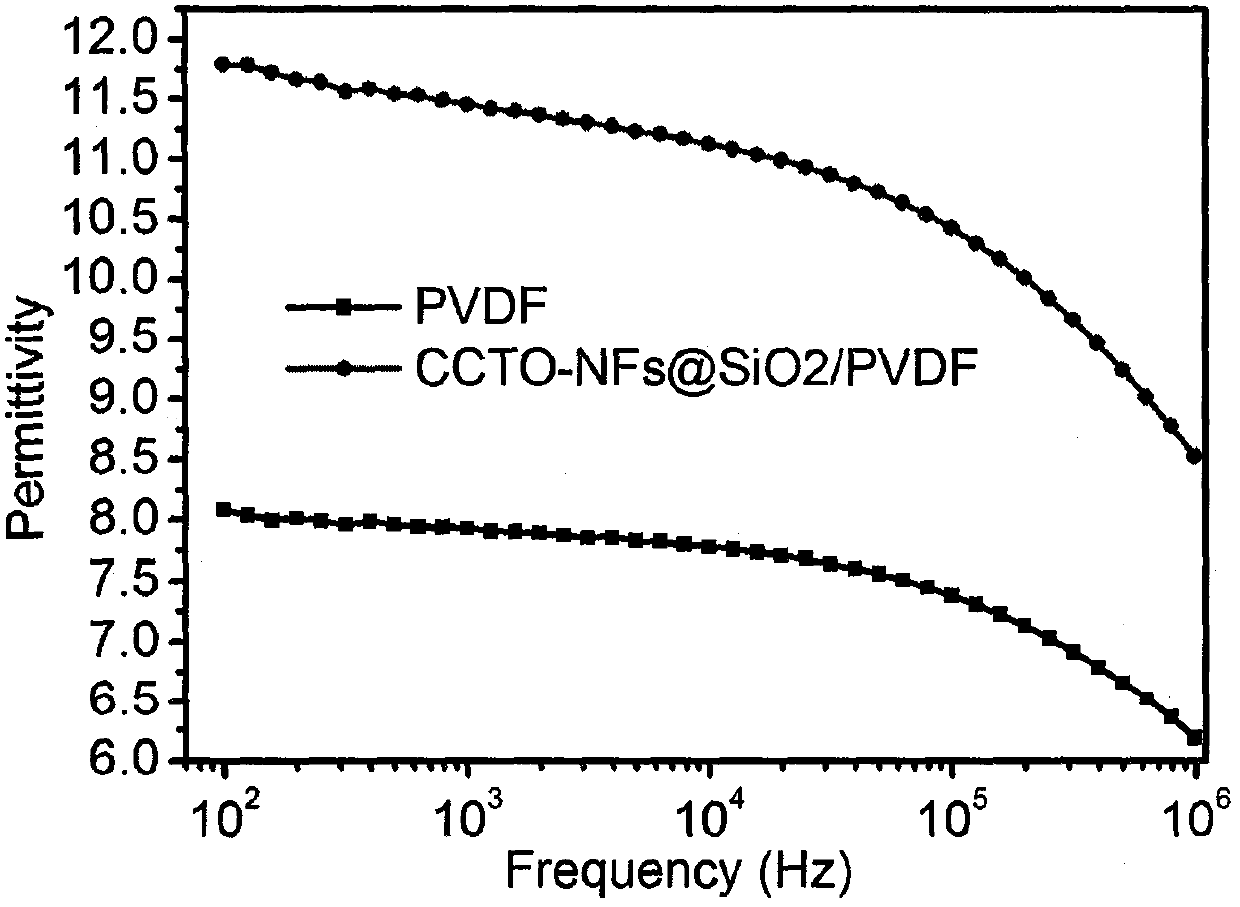

[0020] The composite films prepared in the above examples were tested, and the results showed that the dielectric constant of polyvinylidene fluoride composites coated with copper calcium titanate nanofibers was increased by about 8 compared to pure polyvinylidene fluoride. to 12, while the dielectric loss is only 0.01 to 0.03, effectively suppressi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com