Soldering-resistant printing method of circuit board

A circuit board and solder mask technology, which is applied in the fields of printed circuit manufacturing, printed circuit, and secondary treatment of printed circuit, etc., can solve problems such as redness of circuit, side erosion of green oil bridge, difficult production, etc., and achieve reduction of hole area ink effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

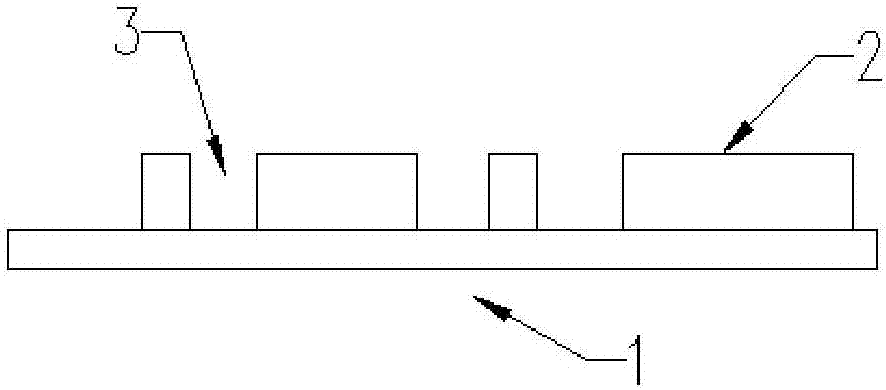

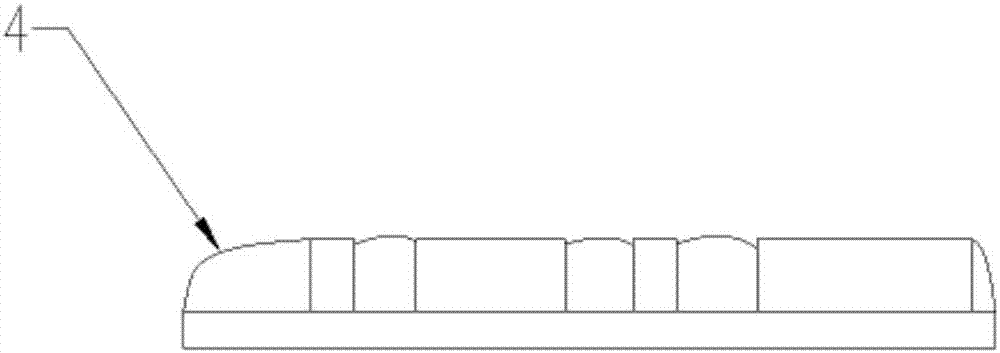

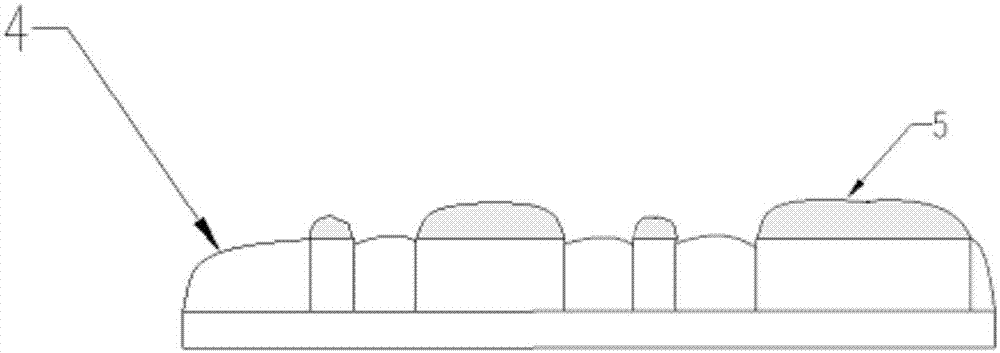

[0033] Solder mask printing is to transfer the ink to the circuit board through the method of screen leakage to form a pattern consistent with the negative. The solder mask is a protective film that prevents bridging during soldering and provides a long-term insulation environment and Anti-chemical protection, forming a beautiful coat of PCB board. In resist printing, green oil, that is, liquid photo solder resist is usually used.

[0034] The specific functions of solder mask printing are as follows:

[0035] A. Solder protection: Leave the through holes and PAD on the board to cover all the circuits and copper surfaces to prevent short circuits during wave soldering and save the amount of solder;

[0036] B. Protective board: prevent the corrosion of moisture, acid-base environment and various electrolytes from oxidizing the circuit and causing electrical performance problems, and prevent external mechanical damage to maintain the insulation effect of the circuit board;

[0037] C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com