Ceramic bonding agent, preparation method and application thereof and diamond grinding tool

A ceramic bond, diamond technology, applied in the manufacture of tools, abrasives, grinding devices, etc., can solve the problems of reducing the strength of diamond abrasive tools, affecting the microstructure of the bond, and short service life, and achieves improved service life and low price. , the effect of improving the reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A method for preparing a vitrified bond according to an embodiment includes the following steps S1-S3.

[0023] Step S1: providing raw materials, including zinc nitrate, lithium nitrate, aluminum nitrate, magnesium nitrate, zirconium nitrate, silica sol, organic fuel, dispersant and organic carbon source.

[0024] Zinc nitrate, lithium nitrate, aluminum nitrate, magnesium nitrate, zirconium nitrate and silica sol in the raw materials provide aggregate for the vitrified bond, and the metal nitrate in the raw material is used as an oxidant in the combustion reaction in step S2, and the organic fuel is used in the reaction As a reducing agent, once the raw material is ignited, it will trigger a violent redox reaction.

[0025] Part of the silica sol is simultaneously converted into silicon carbide nano-whiskers in step S3, English abbreviation: SiC nw , SiC nw play a reinforcing role. The dispersant plays a role in preventing metal nitrate and silica sol from precipitat...

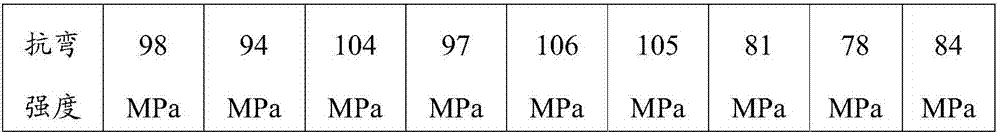

Embodiment 1

[0055] Weigh 0.01mol of zinc nitrate, 0.04mol of lithium nitrate, 0.02mol of aluminum nitrate, 0.01mol of magnesium nitrate, 0.01mol of zirconium nitrate, 0.1mol of silica sol, 0.2mol of urea, 0.025mol of ammonium nitrate, 1.2g of polyacrylamide, and 0.01mol of glucose . The above raw materials are dissolved in water to obtain a mixed solution. After the mixed liquid is ultrasonically sprayed, a large number of fine and dispersed liquid droplets are obtained, and the combustion powder product is obtained after the liquid droplets initiate a combustion reaction at 700 °C in an argon atmosphere furnace. The combustion powder product is subjected to carbothermal reduction reaction at 1400°C and the flow rate of argon gas is 1L / min for 2 hours, so that part of the silicon oxide in the combustion powder product is transformed into SiC nw . The powder of the carbothermal reduction product was incubated in the air at 600 °C for 2 h to obtain the in situ SiC nw Doped vitrified powd...

Embodiment 2

[0057] Weigh 0.01mol of zinc nitrate, 0.042mol of lithium nitrate, 0.022mol of aluminum nitrate, 0.011mol of magnesium nitrate, 0.01mol of zirconium nitrate, 0.11mol of silica sol, 0.3mol of urea, 0.05mol of ammonium nitrate, 1.8g of polyacrylamide, and 0.012mol of glucose . Each of the above was dissolved in an aqueous solution to obtain a mixed solution. After the mixed liquid is ultrasonically sprayed, a large number of fine and dispersed liquid droplets are obtained, and the combustion powder product is obtained after the liquid droplets initiate a combustion reaction at 700 °C in an argon atmosphere furnace. Carbothermal reduction reaction of the combustion powder product at 1300°C and argon flow rate of 1L / min for 4 hours, so that part of the silicon oxide in the combustion powder product is transformed into SiC nw . The powder of the carbothermal reduction product was incubated in the air at 500 °C for 3 h to obtain the in situ SiC nw Doped vitrified powder. Then mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com