Method for separating and recovering iridium salt catalysts for catalyzing light-controlled atom transfer radical polymerization (ATRP)

A technology of atom transfer and catalyst, applied in the field of active polymerization catalyzed by iridium salts, to achieve high reaction efficiency, increase reaction efficiency, simple separation and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

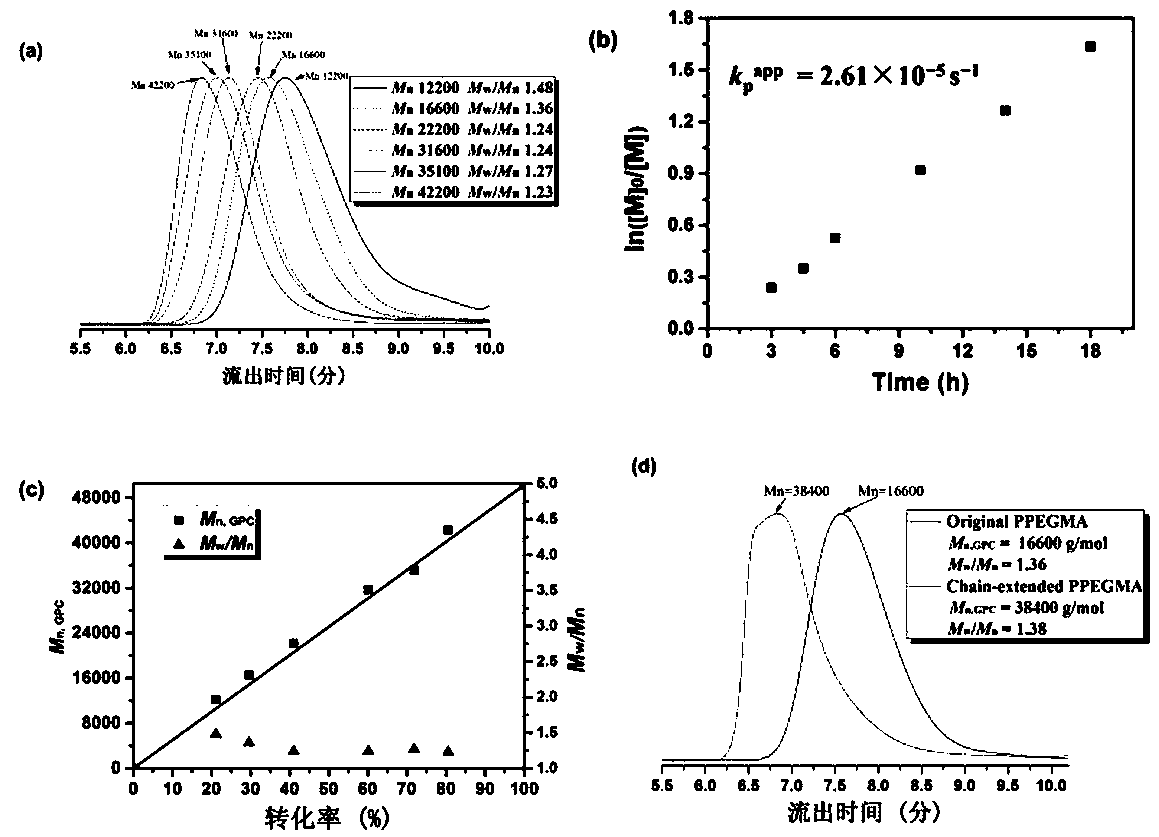

[0037] General steps of photocatalytic photocontrolled atom transfer radical polymerization and separation and recovery method of iridium salt catalyst

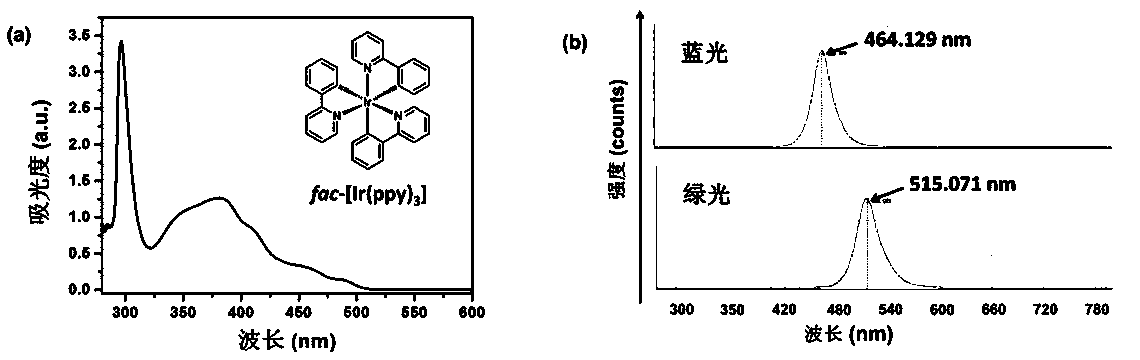

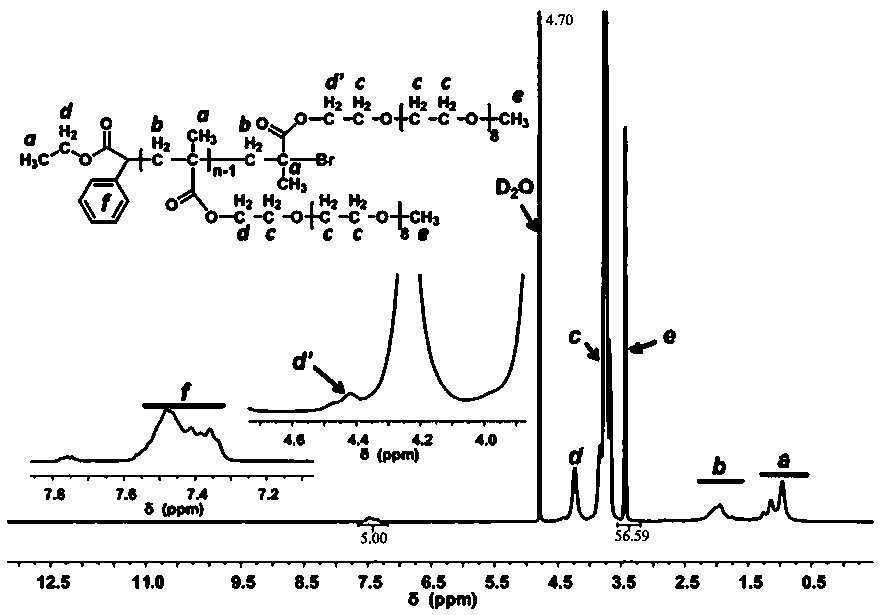

[0038] in [PEGMA] 0 / [EBPA] 0 / [ fac -[Ir(ppy) 3 ]] 0 = 100 / 1 / 0.1 The polymerization process at the molar ratio: PEGMA (1.0 mL, 2.18 mmol), EBPA (3.82 μL, 2.18×10 -2 mmol), fac -[Ir(ppy) 3 ] (1.43 mg, 2.18×10 -3 mmol), and 1,2-dichlorobenzene (1.0 mL) and ethanol (0.5 mL) and a magnetic stir bar were added to a 5 mL dry ampoule. Oxygen was vented from the reaction mixture and an argon (Ar) atmosphere was provided by at least three freeze-pump-thaw cycles. The ampoule was then flame-sealed and transferred to a model Flex Strip-VNC 3528 (4.8 W) blue LED (λmax = 464 nm, 0.15 mW cm -2 ) in a magnetic stirring device under the light strip irradiation. Carry out the polymerization reaction at room temperature (25 ℃), carry out the polymerization during the light time specified in the chart, and cool with an electric f...

Embodiment 2

[0040] Recovery and recycling method of iridium salt catalyst that catalyzes light-controlled atom transfer radical polymerization

[0041] The feature of the present invention is that it can keep the residual amount of metal in the polymer extremely low after polymerization, and the catalyst can be recycled. The chlorobenzene phase (catalyst dissolved) is placed in another clean ampoule of equal volume, and only a predetermined amount of monomer, initiator, and predetermined volume of ethanol are added (the amount of the remaining components added in this recovery experiment is the same as that before recovery equal), the next round of aggregation can be performed. The experiments under different recovery times are shown in Table 1.

[0042] Table 1. Visible light-regulated ATRP catalysts of PEGMA (1.0 mL) ( fac -[Ir(ppy) 3 ]) Loop experiment

[0043]

[0044] a Aggregation condition: 1st use: [PEGMA] 0 / [EBPA] 0 / [ fac -[Ir(ppy) 3 ]] 0 =100 / 1 / 0.1; V PEGMA ...

Embodiment 3

[0047] Preparation of Polymers by Photocontrolled Atom Transfer Radical Polymerization Catalyzed by Different Concentrations of Iridium Salt Catalysts

[0048] The photocatalyst concentration largely determines the reaction speed and controllability of the polymerization. Therefore, the influence of the photocatalyst concentration on the polymerization reaction was explored, and the results are shown in Table 2.

[0049] Table 2. Using fac -[Ir(ppy) 3 ] As a photoredox catalyst, the ATRP process of PEGMA (1.0 mL) with a target degree of polymerization of 50 regulated by visible light. a

[0050]

[0051] a Polymerization conditions: Feed ratio R = [PEGMA] 0 / [EBPA] 0 / [ fac -[Ir(ppy) 3 ]] 0 ; V PEGMA = 1.0 mL, V 邻二氯苯 = 1.0 mL, V 乙醇 = 0.5 mL, temperature = room temperature, polymerized under blue light; b conversion rate by 1 H NMR spectrum determination; c theoretical molecular weight ( M n,th = M EBPA + [PEGMA] 0 / [EBPA] 0 x M PEGMA × conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com