Fabrication method of n-type solar cell

A solar cell, n-type technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of inability to achieve the best passivation performance and contact performance, failure to achieve battery conversion efficiency, narrow battery sintering process window, etc., to achieve passivation Good oxidation performance and contact performance, reduced impact, and improved hydrogen passivation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

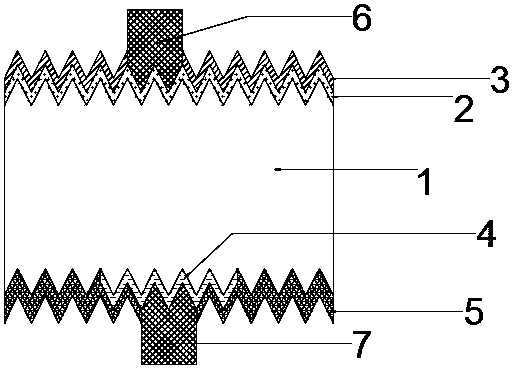

[0038] The preparation method of n-type solar cell is as follows:

[0039] 1) Use 2%-3% KOH solution on the n-type silicon substrate 1 to carry out alkali texturing at a temperature of 70-80 degrees, and use HF and HCl acid solution to clean the surface.

[0040] 2) Prepare the emitter 2. The emitter 2 is prepared by BBr3 liquid-state carrying source diffusion method, and the sheet resistance is 90 ohm / sq.

[0041] 3) Perform wet edge insulation etching. On a chain cleaner, use a mixed acid solution of HF and HNO3 to remove parasitic junctions formed on the edges and back of the battery.

[0042] 4) Perform surface field preparation. The surface field junction preparation method is an external doping source method, and an n+ surface field 4 is formed on the substrate by printing a phosphorous-containing paste and advancing at a high temperature. And the surface field is localized, grid-shaped, with a line width of 150um and a line spacing of 1.6um.

[0043] 5) Prepare the...

Embodiment 2

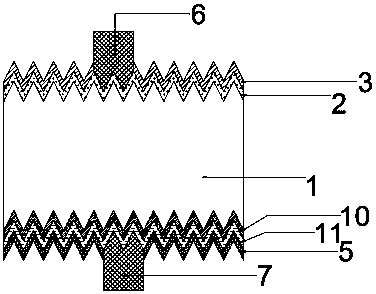

[0049] figure 2 It is the solar cell structure of the second embodiment. The preparation method of n-type solar cell is as follows:

[0050] 1) Use 2%-3% KOH solution on the n-type silicon substrate 1 to carry out alkali texturing at a temperature of 70-80 degrees, and use HF and HCl acid solution to clean the surface.

[0051] 2) Prepare the emitter 2. The emitter 2 is prepared by BBr3 liquid-state carrying source diffusion method, and the sheet resistance is 90 ohm / sq.

[0052] 3) Perform wet edge insulation etching. On a chain cleaner, use a mixed acid solution of HF and HNO3 to remove parasitic junctions formed on the edges and back of the battery.

[0053] 4) Perform surface field preparation. The preparation method of the surface field junction is to grow a 1nm silicon oxide layer as the thin tunnel passivation layer 10 by thermal oxidation. Then, a 100 nm in-situ doped n-type doped polysilicon layer 11 is deposited using a low-pressure vapor-phase chemical depositi...

Embodiment 3

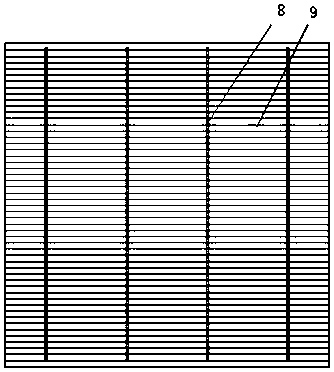

[0059] The preparation method of n-type solar cell is specifically as follows, such as Figure 5 Shown:

[0060] 1) Use 2%-3% KOH solution on the n-type silicon substrate 1 to carry out alkali texturing at a temperature of 70-80 degrees, and use HF and HCl acid solution to clean the surface.

[0061] 2) Prepare the emitter 2 on the front side of the silicon substrate. The emitter 2 is prepared by BBr3 liquid-state carrying source diffusion method, and the sheet resistance is 90 ohm / sq.

[0062] 3) Perform wet edge insulation etching. On a chain cleaner, use a mixed acid solution of HF and HNO3 to remove parasitic junctions formed on the edges and back of the battery.

[0063] 4) Perform surface field preparation. The surface field junction preparation method is an external doping source method, and an n+ surface field 4 is formed on the back of the substrate by using a method of printing phosphorus-containing paste and advancing at a high temperature. And the surface fiel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com