Preparation method of n-shaped double-surface solar cell

A double-sided solar cell, n-type technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem that emitter passivation and anti-reflection cannot be optimized at the same time, battery electrode contact resistance and series resistance are high, and cannot be passivated. In order to improve the overall electrical conversion efficiency, reduce the sintering temperature, achieve the best passivation performance and contact performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

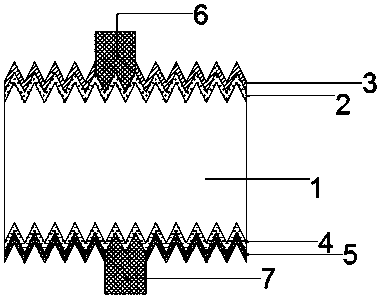

[0036] As an example, such as figure 1 , the preparation method of this n-type double-sided solar cell is as follows:

[0037] 1) Dedamaging and cleaning the n-type silicon substrate 1 . Use NaOH solution for damage treatment, and use hydrofluoric acid, hydrochloric acid for cleaning.

[0038] 2) The emitter is prepared on the back side of the silicon substrate 1 . A BBr3 tubular diffusion process is performed to prepare a pn junction and a p+ doped layer 4 on the back of the silicon substrate 1 . Diffusion peak temperature is 970°C. The diffusion resistance is 90ohm / sq, and oxygen is introduced in the process. After the preparation of the pn junction is completed, a mask is prepared on the back side. The back mask in this embodiment is that during the BBr3 diffusion process, a large amount of oxygen 20slm is introduced in the high temperature process of the diffusion process, and the oxidation time is 90min to form borosilicate glass as mask.

[0039] 3) The front side ...

Embodiment 2

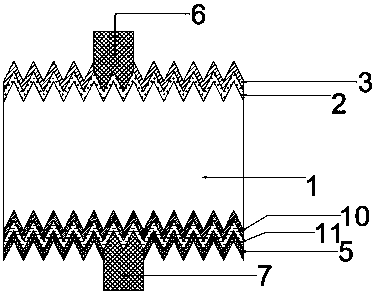

[0048] Such as image 3 , the preparation method of this n-type double-sided solar cell is as follows:

[0049] 1) Use 2%-3% KOH solution on the above-mentioned silicon substrate 1 to carry out alkali texturing at a temperature of 70-80 degrees, and use HF and HCl acid solution to clean the surface.

[0050] 2) The preparation method of the back emitter is to use thermal oxidation to grow a 1nm silicon oxide layer as a thin tunnel passivation layer 10, and then use a low-pressure vapor phase chemical deposition method to deposit a 100nm boron-doped polysilicon layer 11. After annealing, a rear hetero-emitter structure is formed. Sheet resistance is 90ohm / sq.

[0051] 3) The polysilicon deposited on the front side is removed through the back-enhanced chemical vapor deposition 100nm silicon nitride mask and 1%wt concentration of KOH alkali etching cleaning process, and the insulation treatment is completed. Cleaning using a solution containing HF acid. Then dry.

[0052] 4)...

Embodiment 3

[0058] As an example, the preparation method of this n-type double-sided solar cell is as follows:

[0059] 1) Dedamaging and cleaning the n-type silicon substrate 1 . Use NaOH solution for damage treatment, and use hydrofluoric acid, hydrochloric acid mixture for cleaning.

[0060] 2) The emitter is prepared on the back side of the silicon substrate 1 . A BBr3 tubular diffusion process is performed to prepare a pn junction on the back side of the silicon substrate 1 . Diffusion peak temperature is 970°C. The diffusion resistance is 90ohm / sq, and oxygen is introduced in the process. After the preparation of the pn junction is completed, a mask is prepared on the back side. The back mask in this embodiment is that during the BBr3 diffusion process, a large amount of oxygen 20slm is introduced in the high temperature process of the diffusion process, and the oxidation time is 90min to form borosilicate glass as mask.

[0061] 3) The front side is etched in the chain cleanin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com