A kind of high-performance copolyamide hot-melt adhesive composition

A technology of copolyamide and composition, applied in the field of copolyamide hot-melt adhesive composition, which can solve the problems of powder dropping and narrow sintering window, and achieve the effect of accelerating melting speed, good effect and widening process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

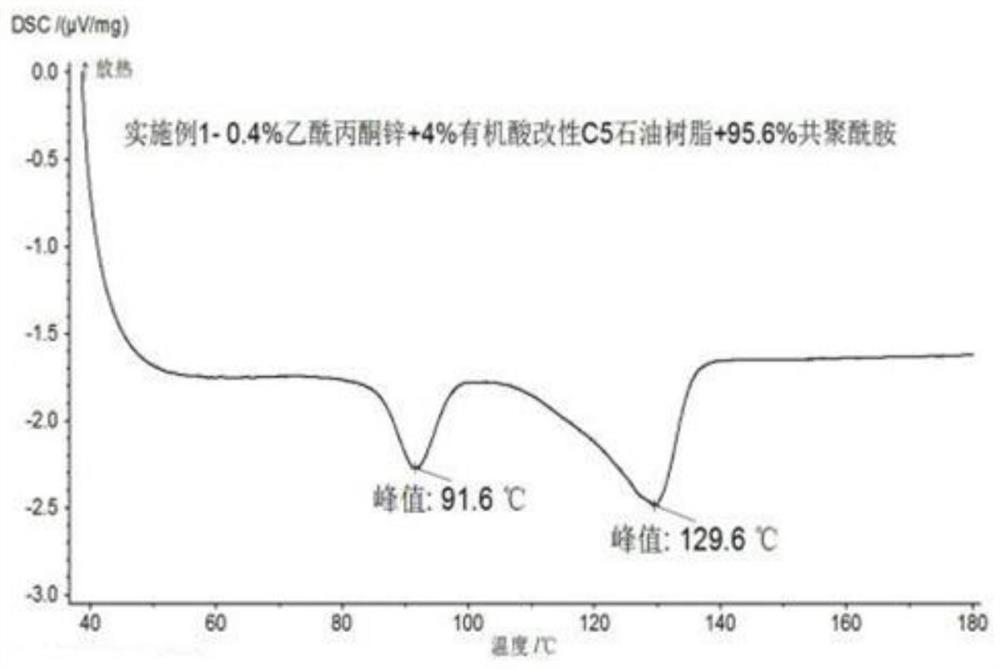

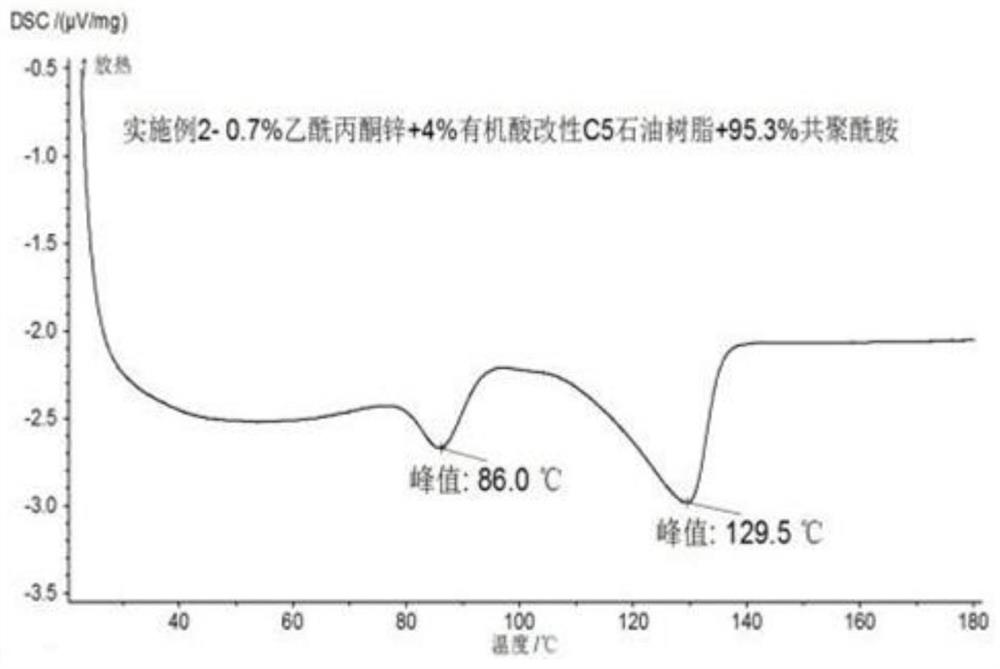

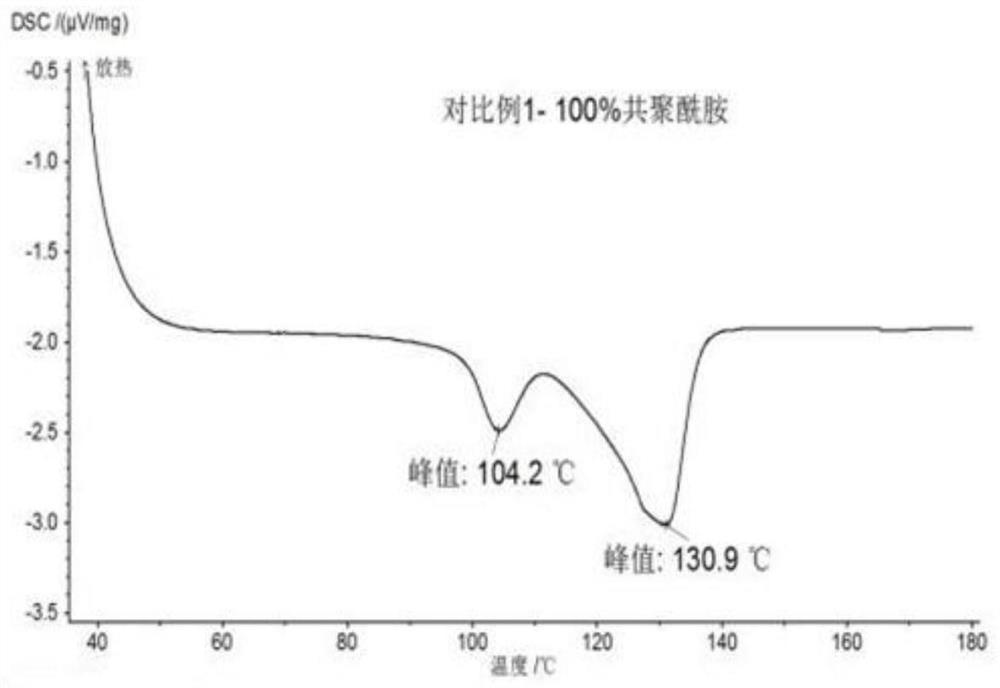

[0031] The technical solutions of the present invention are further explained below in conjunction with specific examples.

[0032] The following materials were used in Examples and Comparative Examples:

[0033] Copolyamide (CoPA) comes from Nantong GCL Hot Melt Adhesive Co., Ltd., which is a copolymer of PA6, PA66 and long-chain nylon. The melting point measured by DSC method is about 130.9°C.

[0034] The organic acid-modified C5 petroleum resin comes from Puyang Ruicheng Chemical Co., Ltd., the product name is RC-AG1100, the acid value is 0.8-1mgKOH / g (according to GB2895-1982 "Determination of the acid value of unsaturated polyester resin"), and the molecular weight is about 2000, with a softening point of 90-100°C, which is obtained by mixing and soaking acrylic organic acid and C5 petroleum resin and then heating and stirring.

[0035] The zinc acetylacetonate comes from Shenyang Haizhongtian Fine Chemical Factory, and is a single type of zinc acetylacetonate with a zi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com