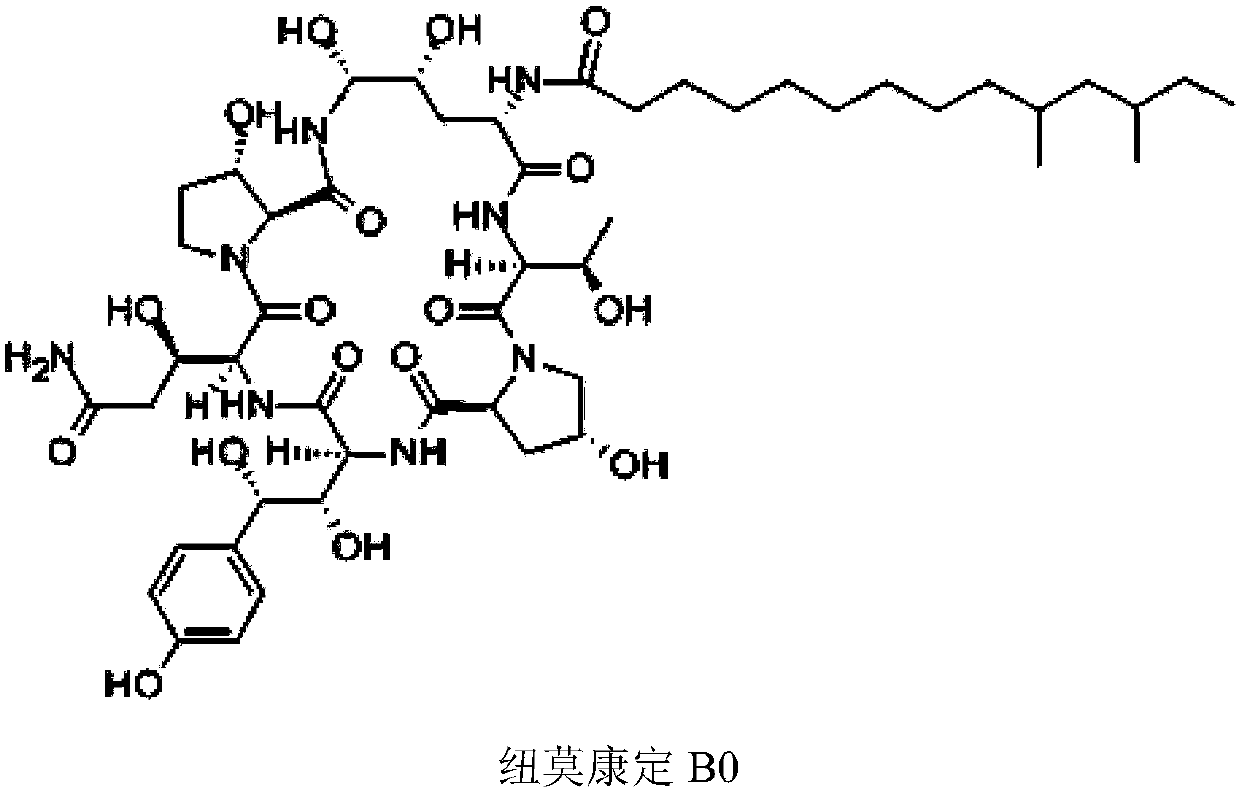

Extraction and purification method of pneumocandins B0

A technology of pneumocidine and purification method, which is applied in the field of biopharmaceuticals, can solve the problems of cumbersome process and difficulty in removing the pigment of fermentation liquid, etc., and achieve the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0050] Neomocontin B0HPLC detection condition of the present invention is as follows: chromatographic column: ODS-C18 (5um);

[0051] Detection wavelength: 210nm;

[0052] Mobile phase: water: acetonitrile (55:45); flow rate: 1.0ml / min

[0053] Column temperature: 40°C.

[0054] The B0 fermentation condition of pneumocidine of the present invention is as follows:

[0055] Strain: ATCC 20957

[0056] Incline culture

[0057] Medium: PDA

[0058] Conditions: 25°C, 12 days

[0059] seed culture

[0060] Medium: 1.0% glucose, 0.5% mannitol, 1.0% glycerin, 0.5% peptone, 2.5% cottonseed powder, 0.5% KH2P0, pH before elimination is 6.8-7.0

[0061] Condition: 25℃, 4 days, shaker speed: 250rpm

[0062] Fermentation culture

[0063] Medium: 8.0% mannitol, 2.0% glucose, 3.0% cottonseed powder, 0.5% yeast powder, 0.5% KHZPO4, adjust pH7.0 before elimination.

[0064] Sterilize at 121°C for 30 minutes, inoculum size is 10%, shake bottle volume is 200ml / 1000ml, place in a constan...

Embodiment 1

[0066] 1) With 1000ml of fermented liquid containing pneumocidine B0, purity 2.6%, fermentation titer is 675mg / L, under the state of stirring, adjust pH value 4.2 with phosphoric acid, add 2% filter aid diatomite, mix Evenly, let stand for 0.5 hour, filter to obtain solid scum;

[0067] 2) The bacterial residue was extracted with 2 times of 95% ethanol, filtered to remove mycelium, and the extract was dark red in color; the alcohol concentration of the extract was adjusted to 20 (V / V), and the yield of this step was 81%;

[0068] 3) Install a D101 column with a height of 25 cm and a diameter of about 4 cm, flow the sample solution through the D101 column at a speed of 5 ml / min, rinse the resin column with purified water and 30% (V / V) ethanol-water solution successively, and then Use 80% (V / V) ethanol-water solution to elute the resin column, collect the eluent rich in pneumocantine B0, the purity is 46% through high-pressure liquid phase detection, the color becomes lighter ob...

Embodiment 2

[0074] 1) Take 1000ml of fermented liquid containing pneumocidine B0, with a purity of 2.7%, and a fermentative titer of 701mg / L. While stirring, adjust the pH value to 6 with phosphoric acid, add 5% filter aid perlite, and mix well , stand still for 0.5 hour, filter to obtain solid bacterial residue, and the color of the bacterial residue is lighter;

[0075] 2) The bacterial residue was extracted with 5 times of 95% ethanol, and the mycelia were removed by filtration to obtain the extract, which was dark red in color; the alcohol concentration of the extract was adjusted to 30% (V / V), and the yield of this step was 87%;

[0076] 3) Install a HPD300 column with a height of 25cm and a diameter of about 4cm, flow the sample solution through the HPD300 column at a speed of 5ml / min, rinse the resin column with purified water and 40% (V / V) ethanol-water solution successively, and then Use 90% (V / V) ethanol-water solution to elute the resin column, collect the eluent rich in pneumo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com