Modified nano zinc oxide-glass fiber-polypropylene composite material and preparation method thereof

A nano-zinc oxide and glass fiber technology, applied in the field of materials, can solve problems such as unsatisfactory results and lack of cohesion, and achieve the effects of increasing roughness and surface area, enhancing interfacial adhesion, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

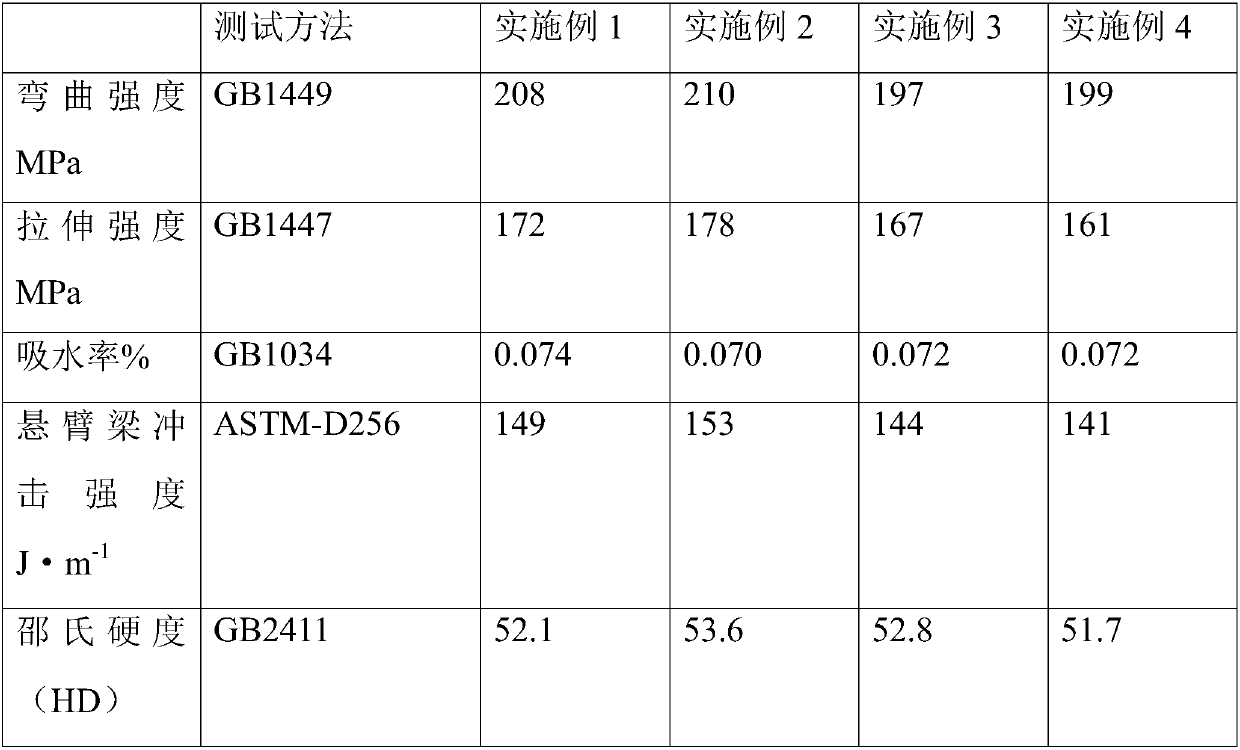

Examples

Embodiment 1

[0022] A modified nano-zinc oxide-glass fiber-polypropylene composite material, including A and B two components, in parts by weight, A component includes 60 parts of medium-melt index homopolypropylene with a melt index of 15g / 10min, 0.15 parts of antioxidant 1010, 0.15 parts of polyethylene wax; component B includes 15 parts of alkali-free glass fibers with a diameter of 8 μm, and 1.5 parts of modified nano-zinc oxide. The modified nano-zinc oxide is made of silane coupling agent KH-570 chemically modifies the surface of nano zinc oxide.

[0023] The preparation includes the following steps:

[0024] (1) Disperse the modified nano-zinc oxide in distilled water according to the proportion of 0.01g / mL, and ultrasonically oscillate for 10 minutes to form a stable modified nano-zinc oxide suspension, which is ready for use;

[0025] (2) Add component A into the mixer to make it fully mixed evenly, add the mixture obtained above into the twin-screw extruder, and the temperature ...

Embodiment 2

[0029]A modified nano-zinc oxide-glass fiber-polypropylene composite material, including A and B two components, according to parts by weight, A component includes 70 parts of medium-melt index homopolypropylene with a melt index of 15g / 10min, 0.2 parts of antioxidant 1010, 0.2 parts of polyethylene wax; component B includes 30 parts of alkali-free glass fibers with a diameter of 8 μm, and 2.5 parts of modified nano-zinc oxide. The modified nano-zinc oxide uses silane coupling agent KH-570 chemically modifies the surface of nano zinc oxide.

[0030] The preparation includes the following steps:

[0031] (1) Disperse the modified nano-zinc oxide in distilled water according to the proportion of 0.01g / mL, and ultrasonically oscillate for 10 minutes to form a stable modified nano-zinc oxide suspension, which is ready for use;

[0032] (2) Add component A into the mixer to make it fully mixed evenly, add the mixture obtained above into the twin-screw extruder, and the temperature...

Embodiment 3

[0036] A modified nano-zinc oxide-glass fiber-polypropylene composite material, including two components A and B, in parts by weight, the A component includes 65 parts of medium-melt index homopolypropylene with a melt index of 15g / 10min, 0.15 parts of antioxidant 1010, 0.15 parts of polyethylene wax; component B includes 17 parts of alkali-free glass fibers with a diameter of 8 μm, and 1 part of modified nano-zinc oxide. The modified nano-zinc oxide uses silane coupling agent KH-570 chemically modifies the surface of nano zinc oxide.

[0037] The preparation includes the following steps:

[0038] (1) Disperse the modified nano-zinc oxide in distilled water according to the proportion of 0.01g / mL, and ultrasonically oscillate for 10 minutes to form a stable modified nano-zinc oxide suspension, which is ready for use;

[0039] (2) Add component A into the mixer to make it fully mixed evenly, add the mixture obtained above into the twin-screw extruder, and the temperature contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com