Manufacturing method of fiber cloth reinforced thermoplastic resin composite material

A resin composite material, thermoplastic resin technology, applied in the field of material science, can solve the problems of high melt viscosity, impregnation cannot be achieved, thermoplastic resin impregnation fiber technical difficulties, etc., to achieve the effect of low equipment investment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Alkali-free glass cloth reinforced polypropylene composite material

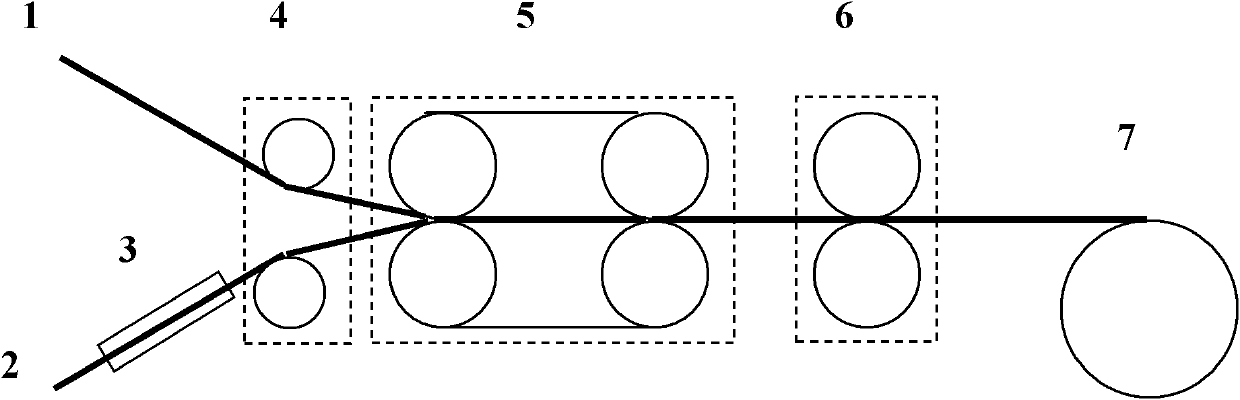

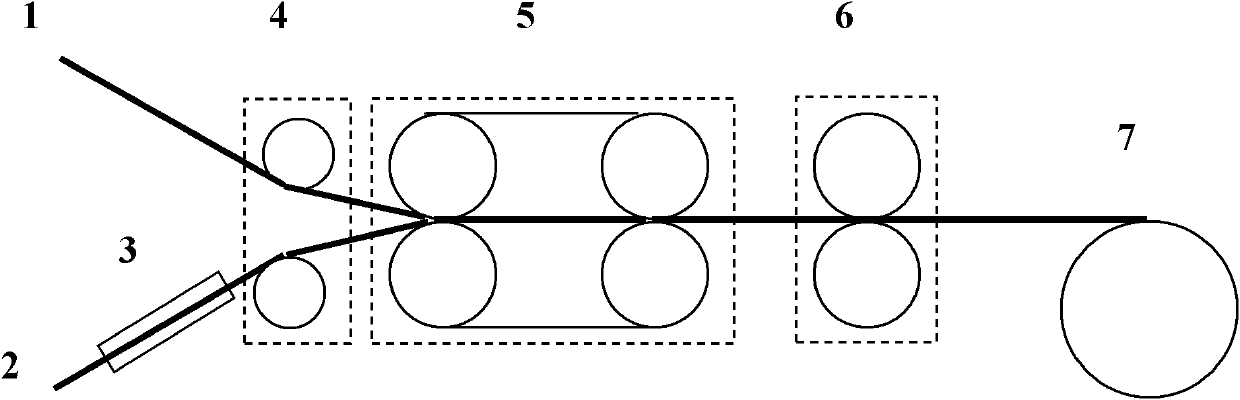

[0038] Such as figure 1 As shown, the non-alkali glass cloth 2 enters the preheating oven 3 to preheat to 230°C after being unrolled. In device 5, the surface temperature of the hot roller is set at about 230°C to keep the polypropylene resin film in a molten and flowing state, so as to realize the complete impregnation of the molten polypropylene resin on the alkali-free glass cloth. The fully impregnated non-alkali glass cloth is drawn into the cooling roller pressing device 6 for cooling, and the cooling roller is cooled by circulating cooling water. Cool the polypropylene resin to below the glass transition temperature to realize the cooling and solidification of the molten resin and keep the surface of the impregnated glass cloth smooth and clean. The distance between the upper and lower rolls of the cooling roll pressing device can be adjusted to 0.4-0.7 mm to control the thickness of the fina...

Embodiment 2

[0040] Glass Mat Reinforced Polypropylene Composites

[0041] Such as figure 1 As shown, after the glass mat 2 is unrolled, it enters the preheating oven 3 to be preheated to 230° C., and the preheated glass mat is laminated together by the guide roller 4 and the polypropylene resin film 1, and then enters the hot roller pressing device 5 for heating. The surface temperature of the roller is set at about 230°C to keep the polypropylene resin film in a molten and flowing state, so as to realize the complete impregnation of the glass mat by the molten polypropylene resin. The fully impregnated glass mat is drawn into the cooling roller pressing device 6 for cooling, and the cooling roller is cooled by circulating cooling water. Cool the polypropylene resin to below the glass transition temperature to realize the cooling and solidification of the molten resin and keep the surface of the impregnated glass mat smooth and clean. The distance between the upper and lower rolls of th...

Embodiment 3

[0043] Kevlar Fiber Cloth Reinforced Polyethylene Terephthalate Composites

[0044] Such as figure 1As shown, the Kevlar fiber cloth 2 is unrolled and enters the preheating oven 3 to be preheated to 300°C, and the preheated Kevlar fiber cloth is laminated with the polyethylene terephthalate resin film 1 through the guide roller 4 together, and then enter the hot roller pressurization device 5, the surface temperature of the hot roller is set at about 300°C to keep the polyethylene terephthalate resin film in a molten flow state, so as to realize the melting of polyethylene terephthalate Complete impregnation of Kevlar fibers with glycol ester resins. The fully impregnated Kevlar fiber is drawn into the cooling roller pressing device 6 for cooling, and the cooling roller is cooled by circulating cooling water. Cool the polyethylene terephthalate resin to below the glass transition temperature to realize the cooling and solidification of the molten resin and keep the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com