Externally filled and prefabricated wood-plastic plate and manufacturing method thereof

A wood-plastic board, coating technology, used in building construction, covering/lining, construction, etc., can solve problems such as bonding fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

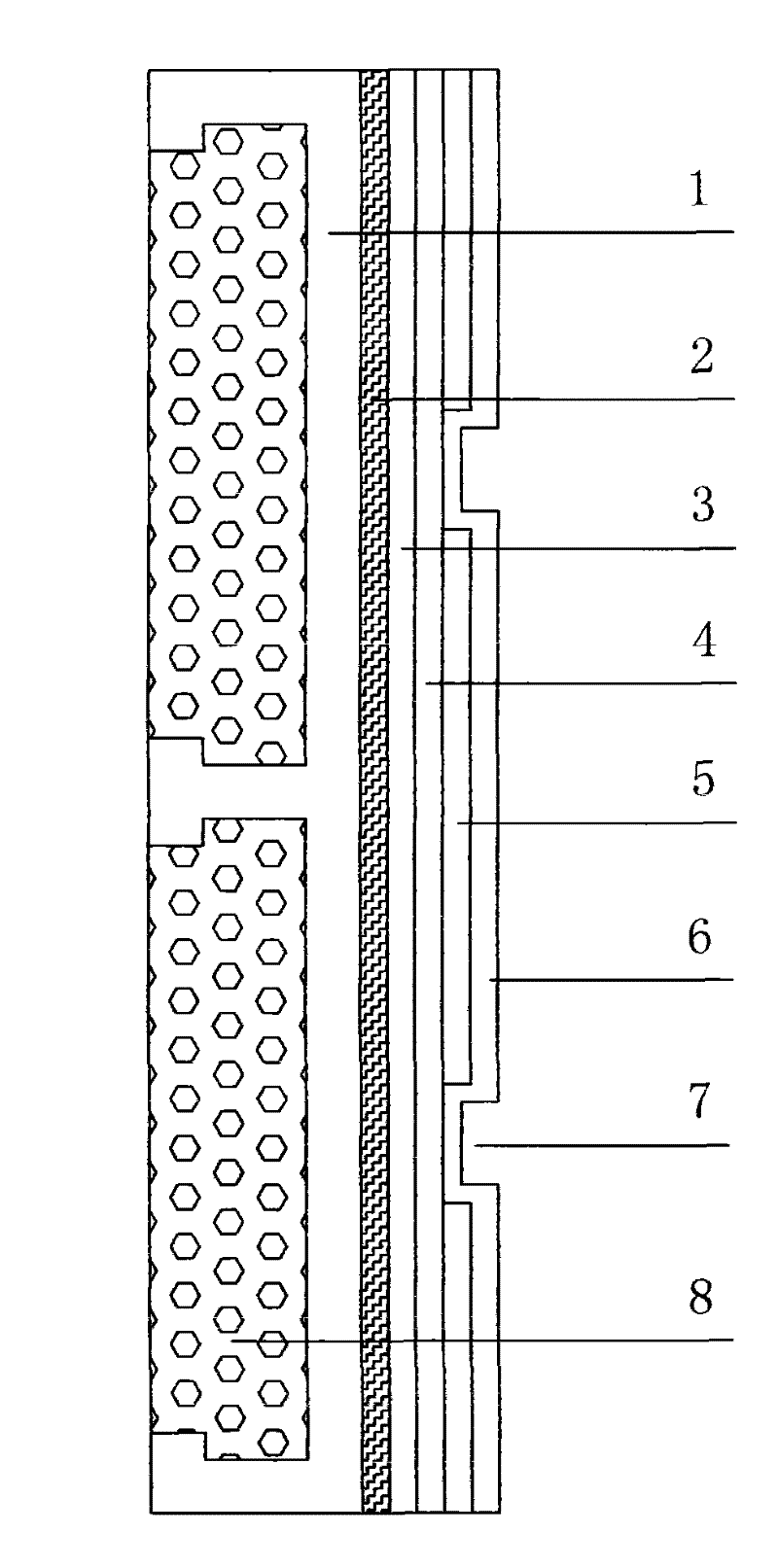

[0022] A schematic diagram of the external filling prefabricated wood-plastic panel system as shown in figure 1 As shown, among them: 1 is the wood-plastic panel with open groove, 2 is the grinding rough surface of the wood-plastic panel, 3 is the interface adhesive of polyurethane, 4 is the bottom coating of polyurethane, and 5 is the surface coating of polyurethane , 6 is the finish paint, 7 is the sunken pattern, and 8 is the insulation material. During production, the opening groove 7 of the wood-plastic board is filled with thermal insulation material 8, the surface of the wood-plastic board 1 is ground into a rough surface 2, the surface of the wood-plastic board rough surface 2 is coated with polyurethane interface adhesive 3, and the polyurethane interface adhesive 3 coat 1-2 mm polyurethane base coat 4, decorative line tape is pasted on polyurethane base coat 4, polyurethane base coat 4 is coated with 2-3 mm polyurethane top coat 5, After the molding tape is removed,...

Embodiment 2

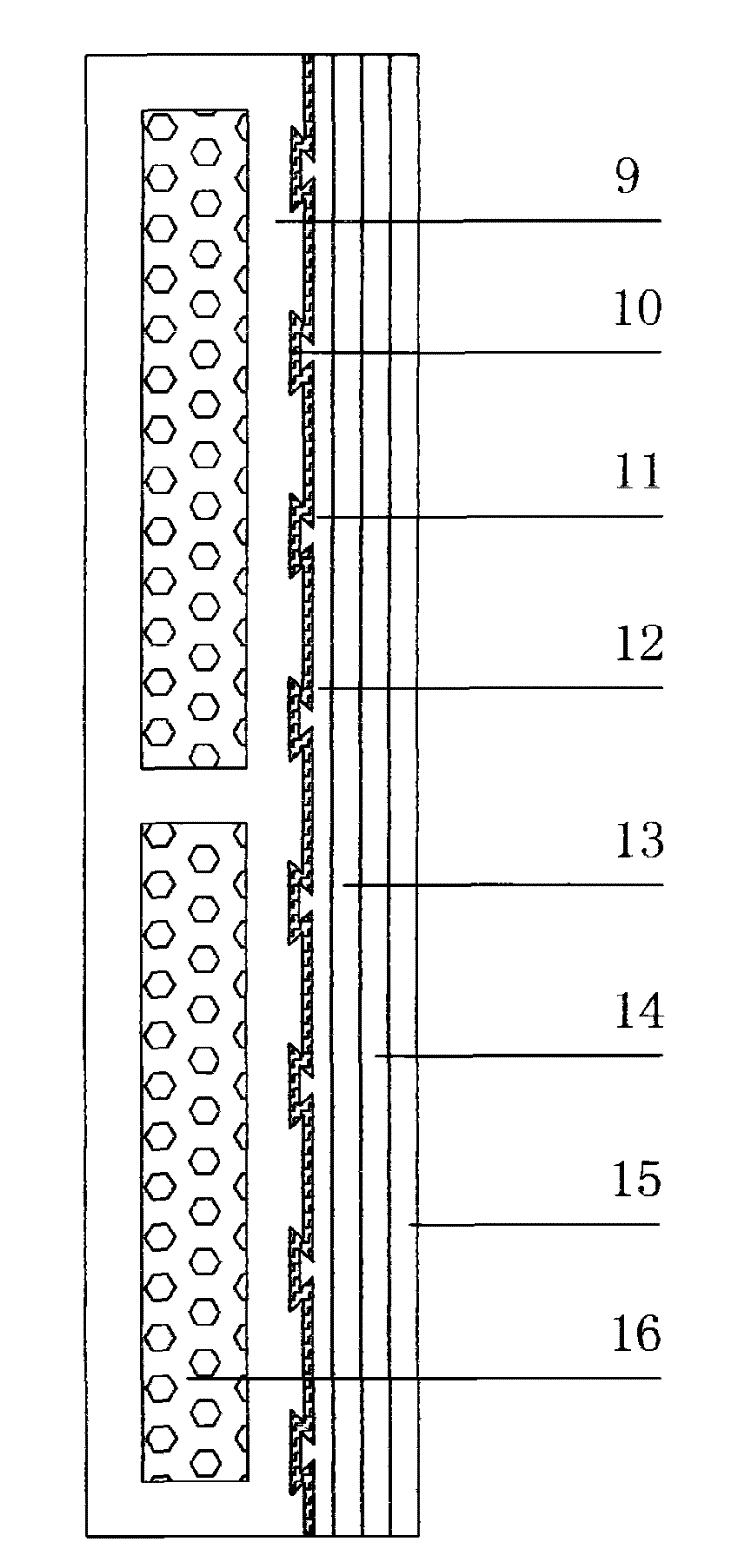

[0024] A schematic diagram of the external filling prefabricated dovetail wood-plastic panel system is shown in figure 2 As shown, among them: 9 is the cavity wood-plastic board, 10 is the dovetail groove, 11 is the grinding rough surface of the wood-plastic board, 12 is the polyurethane interface adhesive, 13 is the polyurethane bottom coat, 14 is the polyurethane Urethane top coat, 15 is fluorocarbon metal paint, 16 is thermal insulation material. During production, the cavity of the wood-plastic board is filled with thermal insulation material 16, the surface of the cavity wood-plastic board 9 and the inside of the dovetail groove 10 are ground into a rough surface 11, and the surface of the wood-plastic board rough surface 11 is coated with polyurethane interface adhesive 12, and the The polyurethane interface adhesive 12 is coated with 1-2 mm polyurethane base coat 13, the polyurethane base coat 13 is embedded in the dovetail groove 10, and the polyurethane base coat 13 ...

Embodiment 3

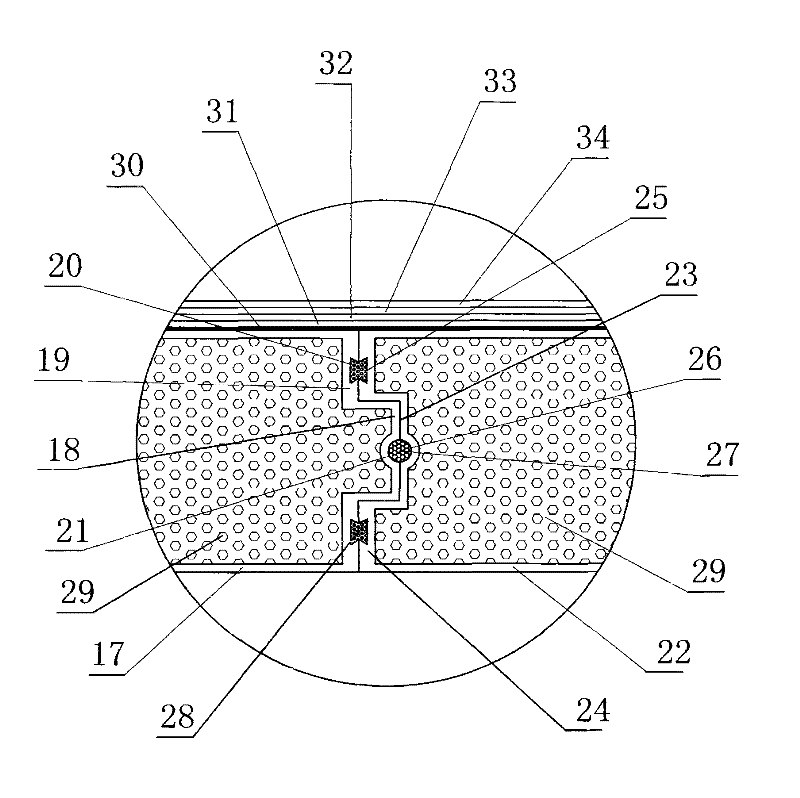

[0026] Schematic diagram of the connection structure of adjacent externally filled prefabricated dovetail wood-plastic panel systems image 3 As shown, among them: 17 is the hollow wood-plastic board, 18 is the tenon of the wood-plastic board, 19 is the vertical plane on the side of the tenon, 20 is the plane dovetail groove, 21 is the groove of the connecting tenon rubber strip, and 22 is the adjacent wood-plastic board , 23 is the connection groove, 24 is the side connection tenon, 25 is the side connection tenon dovetail groove, 26 is the rubber strip groove of the connection groove, 27 is the sealing rubber strip, 28 is the structural glue, 29 is the insulation material, and 30 is the wood-plastic board grinding Shaved surface, 31 is a polyurethane interface adhesive, 32 is a polyurethane primer, 33 is a polyurethane top coat, and 34 is a fluorocarbon paint. During production, the wood-plastic board cavity is filled with thermal insulation material 29, the wood-plastic boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com