PbCaSnAlCeAg grid alloy

An alloy and grid technology, which is applied in the field of new PbCaSnAlCeAg grid alloys, can solve the problems of corrosion deformation of grid alloys, damage to lead-acid batteries, poor alloy cycle life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

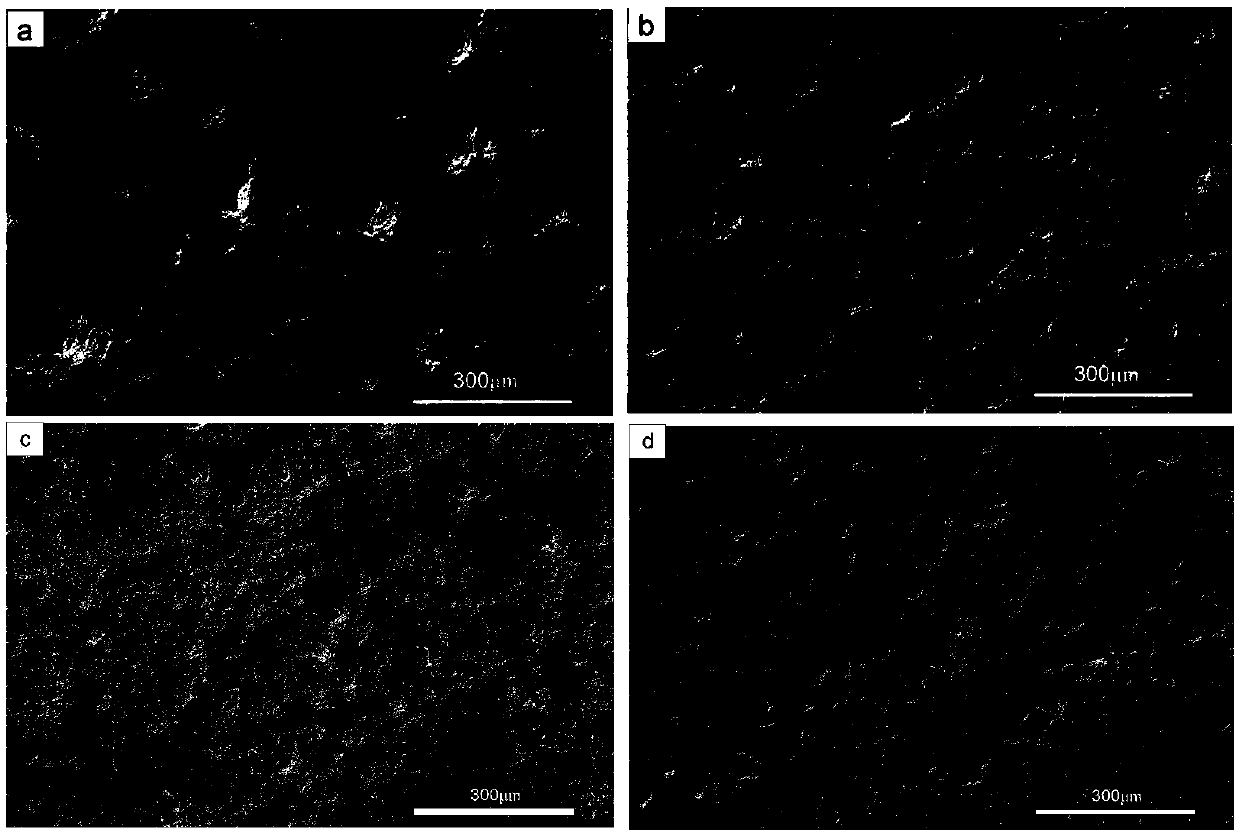

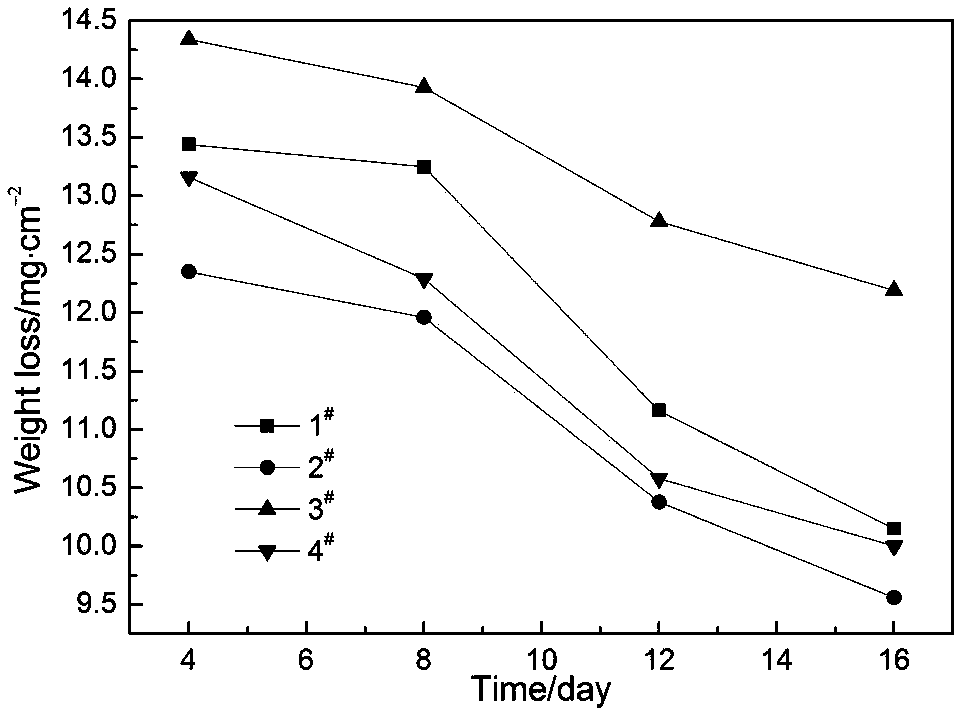

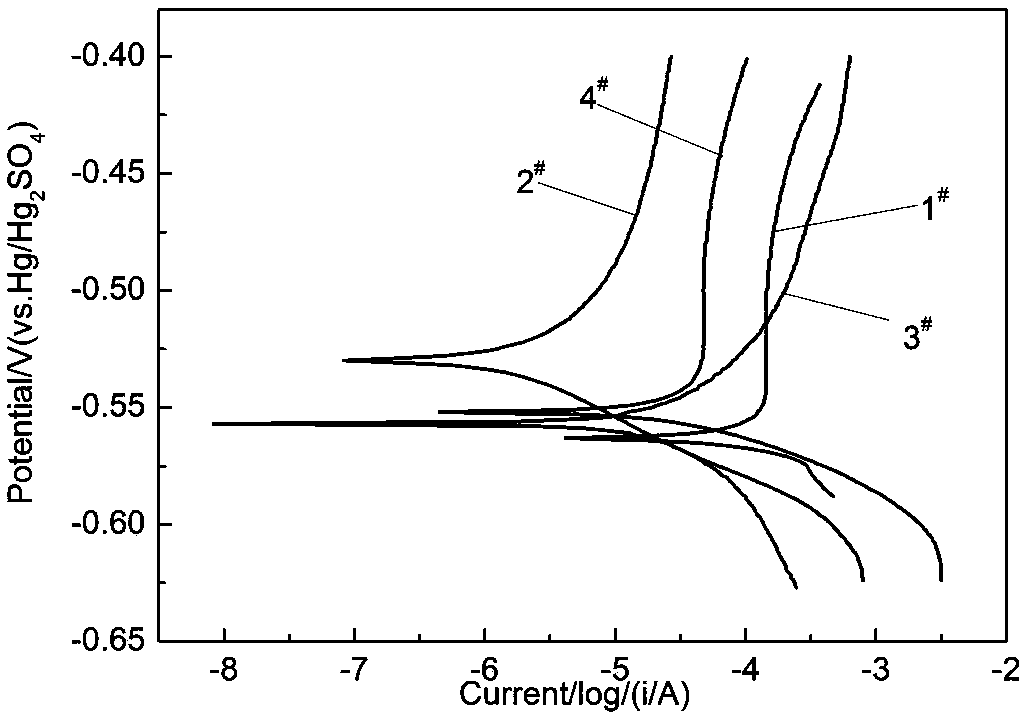

Image

Examples

Embodiment 1

[0024] (1) Design and select the Pb-0.06Ca-1.24Sn-0.15Al-0.01Ce-0.01Ag (wt%) alloy composition ratio, and the preparation method includes the following steps:

[0025] 1) Ingredients: pure Pb (99.99%), pure Ca (99.99%), pure Sn (99.99%), pure Al (99.99%), Ce (99.99%) and Ag (99.99%), according to the mass percentage Prepare their own materials. That is, the weight percentage of the PbCaSnAlCeAg alloy (per 1000 grams of the target alloy can be prepared by 0.6 grams of Ca, 12.4 grams of Sn, 1.5 grams of Al, 0.1 grams of Ce, 0.1 grams of Ag and 985.3 grams of pure Pb) for batching;

[0026] 2) Melting: Clean and preheat the crucible, put the lead ingot preheated to 100°C into the crucible of the electric heating furnace, set the furnace temperature to 400°C, and heat slowly at a heating rate of 10°C / min. After reaching 400°C, add other constituent materials. After the lead alloy is completely melted, keep it warm for 10 minutes, mechanically stir it for 2 minutes, keep it warm ...

Embodiment 2

[0034] (1) Design and select the Pb-0.06Ca-1.24Sn-0.15Al-0.02Ce-0.01Ag (wt%) alloy composition ratio, and the preparation method includes the following steps:

[0035] 1) Ingredients: with pure Pb (99.99%), pure Ca (99.99%), pure Sn (99.99%), pure Al (99.99%) and Ce (99.99%) and Ag (99.99%) as raw materials, according to the The mass percentages are prepared separately. Carry out batching according to the weight percent of above-mentioned PbCaSnAlCeAg alloy (every 1000 grams of target alloys can be formulated by 0.6 gram of Ca, 12.4 gram of Sn, 1.5 gram of Al, 0.2 gram of Ce, 0.1 gram of Ag and 985.2 gram of pure Pb);

[0036] 5) 2) Melting: Clean and preheat the crucible, put the lead ingot preheated to 100°C into the crucible of the electric heating furnace, set the furnace temperature to 400°C, and heat slowly at a heating rate of 10°C / min. After reaching 400°C, add other constituent materials. After the lead alloy is completely melted, keep it warm for 10 minutes, mechan...

Embodiment 3

[0045] (1) Design and select the alloy composition ratio of Pb-0.06Ca-1.24Sn-0.15Al-0.03Ce-0.02Ag (wt%) (wt%), and the preparation method includes the following steps:

[0046] 1) Ingredients: with pure Pb (99.99%), pure Ca (99.99%), pure Sn (99.99%), pure Al (99.99%) and Ce (99.99%) and Ag (99.99%) as raw materials, according to the The mass percentages are prepared separately. Carry out batching according to the weight percent of above-mentioned PbCaSnAlCeAg alloy (every 1000 grams of target alloys can be formulated by 0.6 gram of Ca, 12.4 gram of Sn, 1.5 gram of Al, 0.3 gram of Ce, 0.2 gram of Ag and 985 gram of pure Pb);

[0047] 6) 2) Melting: Clean and preheat the crucible, put the lead ingot preheated to 100°C into the crucible of the electric heating furnace, set the furnace temperature to 400°C, heat slowly, and the heating rate is 5-20°C / min . After reaching 400°C, add other constituent materials. After the lead alloy is completely melted, keep it warm for 10 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com