Ultraviolet light-resistant PBO fiber and preparation method thereof

A UV-resistant and fiber-resistant technology, applied in fiber processing, fiber types, textiles and papermaking, etc., can solve the problem that the micro-morphology of PBO fibers cannot be changed, the UV-resistant agent cannot be bonded and covered, and the shear strength is not significantly improved, etc. problems, to achieve the effect of being conducive to processing, increasing surface properties, and improving firm strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

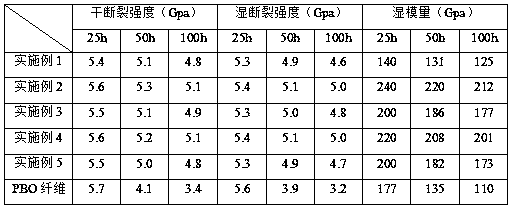

[0038] This embodiment proposes a PBO fiber resistant to ultraviolet light. The PBO fiber resistant to ultraviolet light is made of PBO tow as a raw material, which is sequentially subjected to surface chemical treatment, surface free radical reaction, anti-ultraviolet agent sizing treatment, and drying. The obtained PBO modified fiber has a dry breaking strength of 5.4Gpa, a wet breaking strength of 5.2Gpa and a wet modulus of 140Gpa.

[0039] In order to obtain UV-resistant PBO fibers, first select the PBO fibers produced by the conventional polymerization process, and use the PBO filaments obtained after the PBO fibers are spun, washed with phosphoric acid solution, and dried as raw materials, and then modified. In this embodiment, the spinning method is to dry-jet wet-spin the PBO fibers through twin-screw liquid crystal spinning, wherein the spinning temperature is controlled at 140°C, and the curling speed is 100m / min; phosphoric acid solution is used in the process of wa...

Embodiment 2

[0042] This embodiment proposes a PBO fiber resistant to ultraviolet light. The PBO fiber resistant to ultraviolet light is made of PBO tow as a raw material, which is sequentially subjected to surface chemical treatment, surface free radical reaction, anti-ultraviolet agent sizing treatment, and drying. The obtained PBO modified fiber has a dry breaking strength of 5.6Gpa, a wet breaking strength of 5.4Gpa and a wet modulus of 240Gpa.

[0043] In order to obtain UV-resistant PBO fibers, first select the PBO fibers produced by the conventional polymerization process, and use the PBO filaments obtained after the PBO fibers are spun, washed with phosphoric acid solution, and dried as raw materials, and then modified. In this embodiment, the spinning method is to dry-jet wet-spin the PBO fibers through twin-screw liquid crystal spinning, wherein the spinning temperature is controlled at 200°C, and the curling speed is 150m / min; phosphoric acid solution is used in the process of wa...

Embodiment 3

[0046] This embodiment proposes a PBO fiber resistant to ultraviolet light. The PBO fiber resistant to ultraviolet light is made of PBO tow as a raw material, which is sequentially subjected to surface chemical treatment, surface free radical reaction, anti-ultraviolet agent sizing treatment, and drying. The obtained PBO modified fiber has a dry breaking strength of 5.5Gpa, a wet breaking strength of 5.3Gpa and a wet modulus of 200Gpa.

[0047] In order to obtain UV-resistant PBO fibers, first select the PBO fibers produced by the conventional polymerization process, and use the PBO filaments obtained after the PBO fibers are spun, washed with phosphoric acid solution, and dried as raw materials, and then modified. In this embodiment, the spinning method is to dry-jet wet-spin the PBO fibers through twin-screw liquid crystal spinning, wherein the spinning temperature is controlled at 180°C, and the curling speed is 125m / min; phosphoric acid solution is used in the process of wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com