Flexible dielectric film and organic field effect transistor prepared thereby

A technology of dielectric films and transistors, applied in the field of flexible electronics, can solve problems such as low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

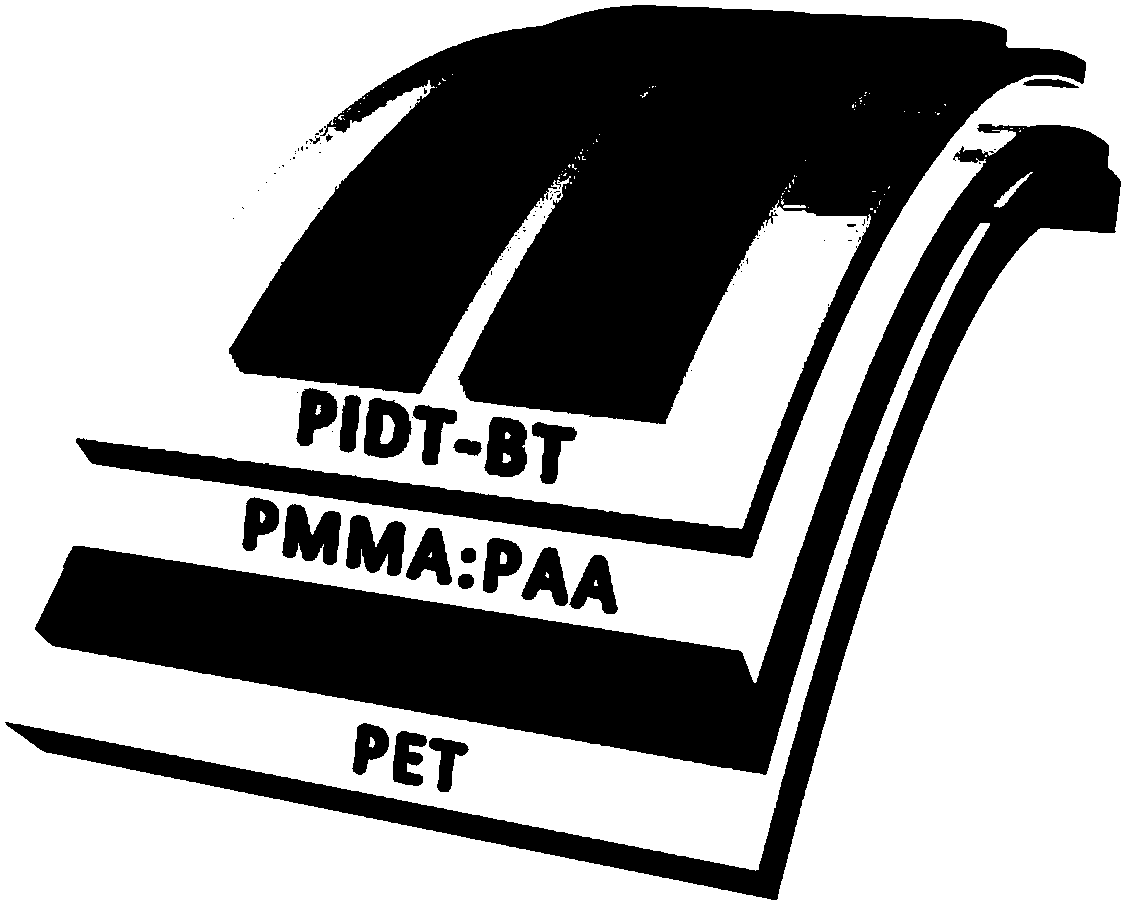

[0109] According to one embodiment of the present invention, the preparation method of the organic field effect transistor of the present invention is as follows:

[0110] 1. Preparation of dielectric film solution: first dissolve PAA in isopropanol, stir magnetically until dissolved at 50°C-80°C, then add PMMA and butanone to it, continue magnetic stirring for 2-6h to form a clear and transparent Mixed solution, wherein the concentration of the solution is 40-80 mg / mL, the PAA accounts for 0.1%-10% of the total mass of PMMA and PAA, and the volume ratio of isopropanol to butanone is 1-3:1;

[0111] 2. Preparation of dielectric layer / gate / substrate assembly: use PET with a thickness of 50-125 μm as the substrate, and cover it with a layer of ITO. After 15 minutes of ultraviolet ozone treatment, the blend prepared in step (1) is passed through conventional The solution spin-coating technology is used to spin-coat on the substrate, and the number of spin-coating is 3 to 6 times....

Embodiment 1

[0115] 1. The bottom-gate top-contact thin film transistor structure is adopted, and the preparation process of the corresponding flexible OFET is as follows:

[0116] (1) Preparation of PMMA:PAA dielectric layer by solution spin coating method and low temperature annealing process

[0117] Step 1: Select a commercially purchased PET-ITO film (square resistance 6-8Ω / cm 2 ), wherein PET is used as the substrate, and ITO is used as the grid electrode, and it is treated with ultraviolet ozone for 15 minutes before use;

[0118] Step 2: Weigh 15mg of PAA and dissolve it in 5mL of isopropanol, stir magnetically at 70°C until dissolved, then add 585mg of PMMA and 5mL butanone to it, and continue to stir magnetically at 70°C for 4h to form clear and transparent PMMA Mixed solution with PAA;

[0119] Step 3: Spin-coat the mixed solution of PMMA and PAA prepared in step 2 on the PET-ITO that has been treated with ultraviolet ozone in advance. The number of times of spin coating is 3 ...

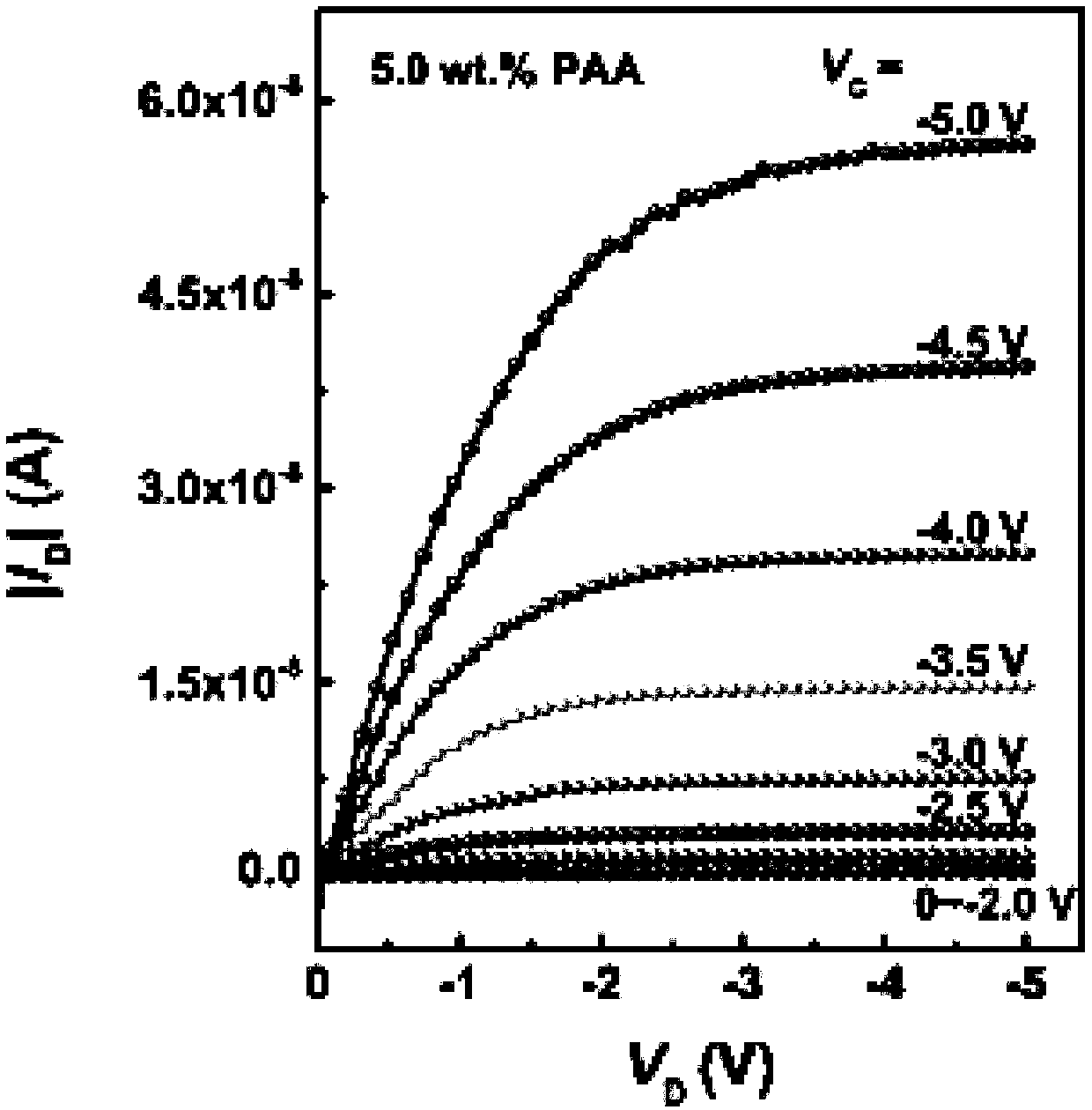

Embodiment 2

[0129] (1) The difference from the preparation process of the flexible OFET in Example 1 is that PAA accounts for 2.5% of the total mass of PAA and PMMA.

[0130] (2) Performance testing of flexible OFET devices:

[0131] Use the Agilent 4155c Semiconductor Parameter Analyzer to test the transfer characteristic curve of the flexible OFET after bending (such as Figure 4 shown), where the source-drain voltage V D =-4V, the bending radius of the flexible OFET is r=15mm, the substrate thickness is 125μm, and the bending times are 0, 100, 200, 500, 1000 and 1500 times, respectively, and the bending times have no obvious attenuation on the electrical properties of the flexible OFET, showing good stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com