A kind of organic fluorine modified polysiloxane acrylate copolymer emulsion finishing agent

A technology of polysiloxane acrylate and copolymer emulsion, which is applied in fiber treatment, plant fiber, textiles and papermaking, etc. It can solve the problem of poor chemical medium resistance of organic silicon materials, poor low temperature resistance of organic fluorine materials, and lower film surface Free energy and other issues to achieve the effects of good emulsion stability, good tensile properties, and good water and oil repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

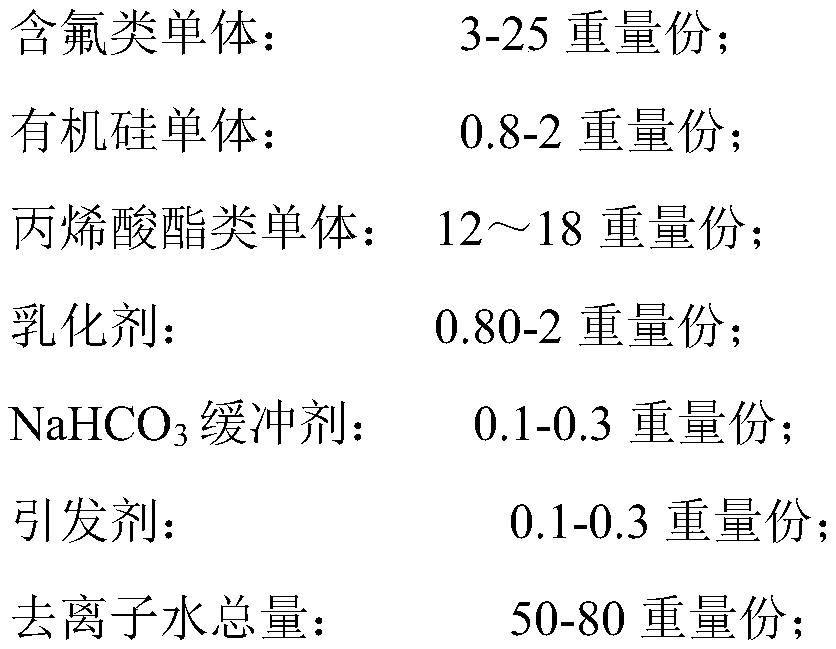

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 (basic preparation method)

[0034] A preparation method of organofluorine-modified polysiloxane acrylate copolymer emulsion finishing agent, comprising the steps of:

[0035] Prepare 30 mL of emulsifier solution with 0.45 g of washing powder and 0.75 g of octylphenol polyoxyethylene ether (OP-10) with deionized water, and add 0.150 g of potassium persulfate and ammonium persulfate (mass ratio: 1:1). Prepare 12mL initiator aqueous solution with deionized water.

[0036] 5.4g of butyl acrylate, 1.8g of ethyl methacrylate, 3.80g of dodecafluoroheptyl methacrylate, 0.4g of methylphenylcyclotrisiloxane, 0.2g of glycidyl acrylate, NaHCO 3 0.05 g of buffer was added to a four-necked bottle containing 10 mL of emulsifier solution, ultrasonically dispersed for 20 min, and then mechanically stirred for 15 min to obtain the pre-emulsion required for the reaction. Ethyl methacrylate 4.8g, butyl acrylate 2.4g, glycidyl acrylate 0.2g, emulsifier 20mL, NaHCO 3 Add 0.1...

Embodiment 2

[0040] A preparation method of organofluorine-modified polysiloxane acrylate copolymer emulsion finishing agent, comprising the steps of:

[0041] Prepare 30 mL of emulsifier solution with 0.45 g of washing powder and 0.90 g of octylphenol polyoxyethylene ether (OP-10) with deionized water, and add 0.175 g of potassium persulfate and ammonium persulfate (mass ratio: 1:2) with Deionized water was prepared into 12mL initiator aqueous solution.

[0042] Hydroxyethyl phosphate acrylate 0.2g, butyl acrylate 5.4g, ethyl methacrylate 1.8g, emulsifier solution 20mL, NaHCO 3 Add 0.1g of buffer and 20mL of deionized water into the four-necked flask, and then place the four-necked flask in an ultrasonic processor for ultrasonic treatment for a period of time:

[0043] Among them, the ultrasonic phase uses stepwise ultrasonic and the following settings are made to the instrument:

[0044] 1) Set the ultrasonic processor at 20°C, power 80%, and ultrasonic treatment for 5 minutes

[0045...

Embodiment 3

[0057] A preparation method of organofluorine-modified polysiloxane acrylate copolymer emulsion finishing agent, comprising the steps of:

[0058] Prepare 30 mL of emulsifier solution with 0.45 g of washing powder and 0.90 g of octylphenol polyoxyethylene ether (OP-10) with deionized water, and use 0.240 g of potassium persulfate and ammonium persulfate (mass ratio 1:2) Ionized water was prepared into 12mL initiator aqueous solution. Glycidyl acrylate 0.4g, butyl acrylate 5.4g, ethyl methacrylate 1.8g, emulsifier 20mL, NaHCO 3 Add 0.1g of buffer and 20mL of deionized water into the four-necked flask, and then place the four-necked flask in an ultrasonic processor for ultrasonic treatment:

[0059] Among them, the ultrasonic phase uses stepwise ultrasonic and the following settings are made to the instrument:

[0060] 1) Set the ultrasonic processor at 20°C, power 100%, and ultrasonic treatment for 5 minutes

[0061] 2) Set the ultrasonic processor to 40°C, power 80%, and ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

| gel rate | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com