Samarium-containing rare earth polishing powder and preparation process thereof

A rare earth polishing powder and preparation process technology, applied in polishing compositions containing abrasives, etc., can solve the problems of low value of samarium element, inability to form market sales, resource backlog, etc., and achieve wide source of raw materials, good grinding efficiency and recycling. The effect of using performance and pollution is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

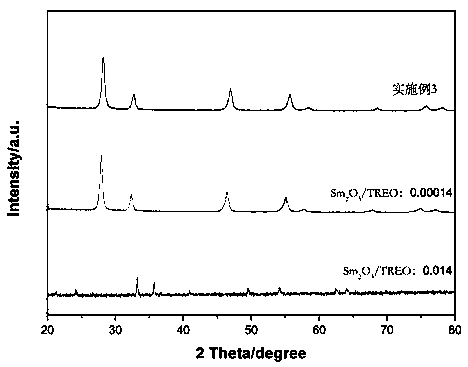

[0027] The rare earth compound is prepared as a salt solution, and the composition of the salt solution is calculated as Sm in molar ratio 2 o 3 / TREO=1.4×10 -4 , La 2 o 3 / TREO=0.104,Pr 7 o 11 / TREO=0.0022,Nd 2 o 3 / TREO=0.0045, the balance is CeO 2 / TREO=0.36, the molar concentration of the salt solution is 0.59mol / L. Add 1m into the reaction vessel 3 The raw material solution was heated up to 96°C. Ammonium bicarbonate is prepared as a solution of 0.885 mol / L, and ammonium fluoride is added to the ammonium bicarbonate solution so that the fluoride ion concentration in the ammonium bicarbonate solution is 0.236 mol / L. Press filter the fluorine-containing ammonium bicarbonate solution, and take the clear liquid. Add fluorine-containing ammonium bicarbonate solution into the reactor until the pH value of the system is 7.0, and the synthesis process control time is 5 hours. The precipitate was washed and filtered, dried at 300°C for 36 hours, and the dried material ...

Embodiment 2

[0029] The rare earth compound is prepared as a salt solution, and the composition of the salt solution is calculated as Sm in molar ratio 2 o 3 / TREO=0.014, La 2 o 3 / TREO=0.104,Pr 7 o 11 / TREO=8.6×10 -6 ,Nd 2 o 3 / TREO=2.97×10 -4 , the balance is CeO 2 / TREO=0.28, the molar concentration of the salt solution is 1.78mol / L. Add 1m into the reaction vessel 3 The raw material solution was heated up to 90°C. Ammonium bicarbonate is prepared as a solution of 2.67 mol / L, and ammonium fluoride is added to the ammonium bicarbonate solution so that the fluoride ion concentration in the ammonium bicarbonate solution is 0.712 mol / L. Press filter the fluorine-containing ammonium bicarbonate solution, and take the clear liquid. Add fluorine-containing ammonium bicarbonate solution into the reactor until the pH value of the system is 7.0, and the synthesis process control time is 0.5 hour. The precipitate was washed and filtered, dried at 650°C for 6 hours, and the dried mater...

Embodiment 3

[0031] The rare earth compound is prepared as a salt solution, and the composition of the salt solution is calculated as Sm in molar ratio 2 o 3 / TREO=0.014, La 2 o 3 / TREO=0.06,Pr 7 o 11 / TREO=0.0022,Nd 2 o 3 / TREO=0.0045, balance CeO 2 / TREO=0.37, the molar concentration of the salt solution is 0.59mol / L. Add 1m into the reaction vessel 3The raw material solution was heated up to 93°C. Sodium carbonate is prepared as a 2.655mol / L solution, and sodium fluoride is added to the ammonium bicarbonate solution to make the fluoride ion concentration in the ammonium bicarbonate solution 0.59mol / L. Press filter the fluorine-containing ammonium bicarbonate solution, and take the clear liquid. Add fluorine-containing ammonium bicarbonate solution into the reactor until the pH value of the system is 7.0, and the synthesis process control time is 2.5 hours. The precipitate was washed and filtered, dried at 600°C for 12 hours, and the dried material was calcined at 1080°C for 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com