Harmless and comprehensive utilization method of secondary aluminum dross

A secondary aluminum, harmless technology, applied in the preparation of alkaline earth metal aluminate/alumina/aluminum hydroxide, chloride preparation, fluoride preparation, etc., can solve the problem of high production cost, large energy consumption, electrolysis Reduce the service life of the tank and other problems, and achieve the effects of reducing production costs, wide applicability, and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

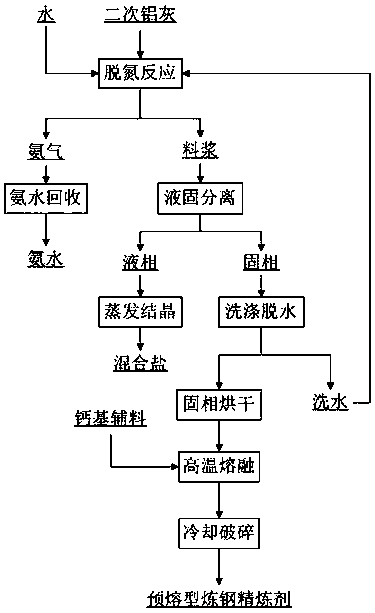

Image

Examples

Embodiment 1

[0026] The secondary aluminum ash produced by the aluminum ash recovery metal aluminum is processed by the ash sieving method, which is configured into a slurry according to the liquid-to-solid ratio of 1:1, and the deamination reaction is carried out in a sealed deamination reactor with a reaction temperature of 120°C. The reaction time is 1h, the reacted ammonia gas is condensed to recover ammonia water, the reacted slurry is separated from liquid to solid, and the liquid phase is evaporated and crystallized at 150°C to obtain a mixture of chloride and fluoride salts; separated denitrification aluminum ash solid phase washing , After dehydration and drying, it is mixed with calcium oxide powder (CaO content is 96%) according to the weight ratio of 1:0.3. The melting reaction is carried out at a high temperature of 1300℃ for 4 hours. After the reaction, the aluminum is obtained by cooling, crushing and grinding. Salt cement.

[0027] The nitrogen decomposition rate of the second...

Embodiment 2

[0029] The secondary aluminum ash produced by the aluminum ash recovery by the rotary kiln method is used to prepare a slurry according to the liquid-to-solid ratio of 4:1, and the deamination reaction is carried out with stirring in a sealed deamination reactor. The reaction temperature is 20°C and the reaction time 10h, the reacted ammonia gas absorbs ammonia water with water, the reacted slurry undergoes liquid-solid separation, and the liquid phase is evaporated and crystallized at 120°C to obtain a mixture of chloride and fluoride salts; the separated denitrification aluminum ash is solid-phase washed, dehydrated, After drying, it is mixed with limestone (CaO content is 54%), and the weight ratio is 1:3. The melting reaction is carried out at a high temperature of 1400 ℃ for 3 hours. After the reaction, the pre-melted calcium aluminate is obtained by cooling, crushing and screening treatments. Agent.

[0030] The nitrogen decomposition rate of the secondary aluminum ash in t...

Embodiment 3

[0032] The secondary aluminum ash produced by the aluminum ash recovery by the squeezing cooling method is used to prepare a slurry according to a liquid-to-solid ratio of 6:1, and conduct agitation and deamination reaction in a sealed deamination reactor. The reaction temperature is 90°C and the reaction time 6h, the reacted ammonia vapor is condensed to recover ammonia water, the reacted slurry undergoes liquid-solid separation, and the liquid phase is evaporated and crystallized at 100°C to obtain a mixture of chloride and fluoride; the separated denitrified aluminum ash is washed and dehydrated in solid phase , After drying, it is mixed with calcium carbide slag (CaO content is 62%), and the weight ratio is 1:1.4. The melting reaction is carried out at a high temperature of 1500 ℃ for 2 hours. After the reaction, the pre-melted aluminate is obtained by cooling, crushing and screening. Calcium refining agent.

[0033] The nitride decomposition rate of the secondary aluminum as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com