Antibacterial filter element for automobile air conditioner and preparation process of antibacterial filter element

A technology for automotive air conditioners and filter elements, which is applied in air treatment equipment, filtration separation, vehicle components, etc., can solve problems such as troubles and restrictions on emission methods, and achieve the effects of increasing degradation performance, low preparation cost, and adsorbing and degrading harmful gases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

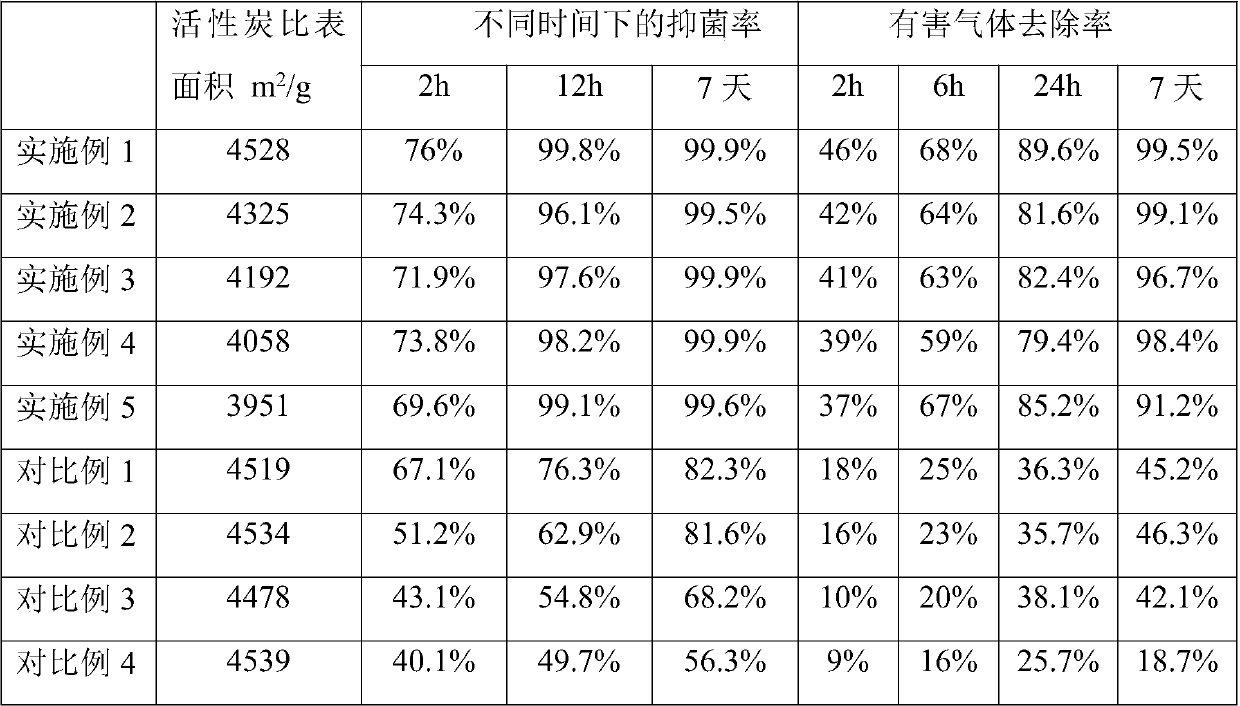

Examples

Embodiment 1

[0042] Put 2kg of straw into a muffle furnace, pass in argon, dry at 140°C for 10 hours, then raise the temperature to 500°C, and calcinate for 4 hours to obtain activated carbon, and then place it in water vapor at 130°C for 2.5 hours to obtain activated carbon ;

[0043] Grind 10g of Evodia rutaecarpa, 3g of Clematis, 8g of Sanbaicao, 15g of lavender, 6g of loofah, 5g of lemon, and 10g of fritillaria into powder, pass through a 200-mesh sieve, and then put it under steam with a vapor pressure of 230 KPa and a temperature of 120°C. placed in the middle for 60min to obtain Chinese herbal medicine powder;

[0044]Mix 0.5mol ferric chloride, 0.5mol cobalt chloride, 0.5mol copper chloride and 6mol citric acid in water, then add a mixture of sodium carbonate and sodium bicarbonate (molar ratio 1:1) and 50g of activated carbon to adjust the solution pH to 6.3, stirred until the solution was in a gel state, added 0.1mol sodium hydroxide, mixed evenly, dried at 100°C for 2 hours, an...

Embodiment 2

[0048] Put 2kg of orange peels into a muffle furnace, pass in argon, dry at 150°C for 18 hours, then raise the temperature to 400°C, and calcinate for 6 hours to obtain activated carbon, and then place it in water vapor at 120°C for 2.5 hours to obtain Activated carbon;

[0049] Grind 5g of Euphorbia japonica, 16g of lavender, and 18g of loofah into powder, pass through a 200-mesh sieve, and then place it in steam with a vapor pressure of 320 KPa and a temperature of 120°C for 90 minutes to obtain a Chinese herbal medicine powder;

[0050] Mix 0.2mol ferric nitrate, 0.1mol zinc nitrate, 0.1mol manganese nitrate and ethylenediamine in water evenly, then add pyridine and 30g activated carbon, adjust the pH of the solution to 6.7, stir until the solution is in a gel state, add magnesium hydroxide, After mixing evenly, dry at 80°C for 1 h, and then calcinate in an argon atmosphere for 5 h at a calcination temperature of 500°C to obtain magnetic nanoparticles;

[0051] Mix magneti...

Embodiment 3

[0054] Put 2kg of sawdust into a muffle furnace, pass in argon, dry at 120°C for 5 hours, then raise the temperature to 600°C, and calcinate for 2 hours to obtain activated carbon, and then place it in water vapor at 150°C for 2.5 hours to obtain activated carbon ;

[0055] Grind 15g mugwort leaves, 20g magnolia officinalis, and 26g fennel into powder, pass through a 200-mesh sieve, and then place it in steam with a steam pressure of 150 KPa and a temperature of 140°C for 45 minutes to obtain a Chinese herbal medicine powder;

[0056] Mix 0.3mol cobalt chloride, 0.5mol nickel chloride, 0.2mol tin chloride and ammonia water in water, then add alkaline substances and 40g activated carbon, adjust the pH of the solution to 7, stir until the solution is in a gel state, add hydrogen Potassium oxide, mixed evenly, dried at 120°C for 3 h, and then calcined in an argon atmosphere for 2 h at a calcining temperature of 300°C to obtain magnetic nanoparticles;

[0057] Mix 30g of magnetic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com