Apparatus and method for preparing ultrafine WO3

A liquid storage tank and microchannel technology, which is applied in the field of powder metallurgy, can solve the problems of long preparation cycle, high equipment requirements, and easy powder agglomeration, and achieve good industrialization prospects, high control precision, and narrow particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Weigh 3.29g of Na 2 WO 4 Dissolve 5 mL of acetic acid in deionized water, and prepare 100 mL of 0.1 mol / L sodium tungstate solution as reaction solution A. Measure 12.5 mL of concentrated hydrochloric acid, dilute it to 100 mL with deionized water, prepare 1.5 mol / L hydrochloric acid as reaction solution B, and transfer it into two storage tanks respectively.

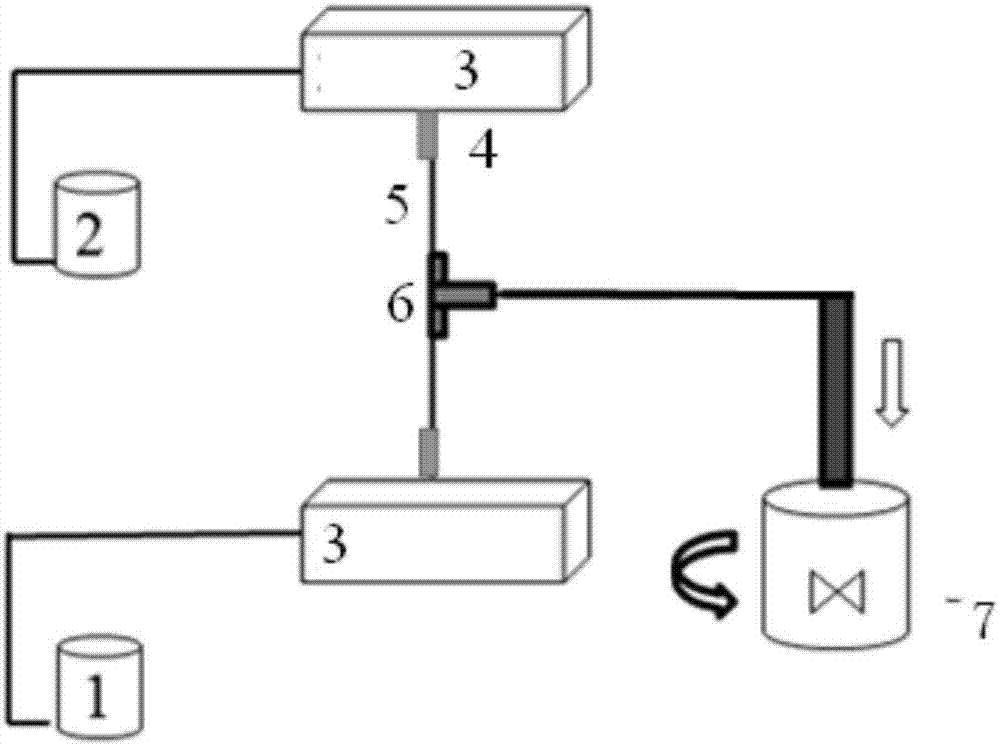

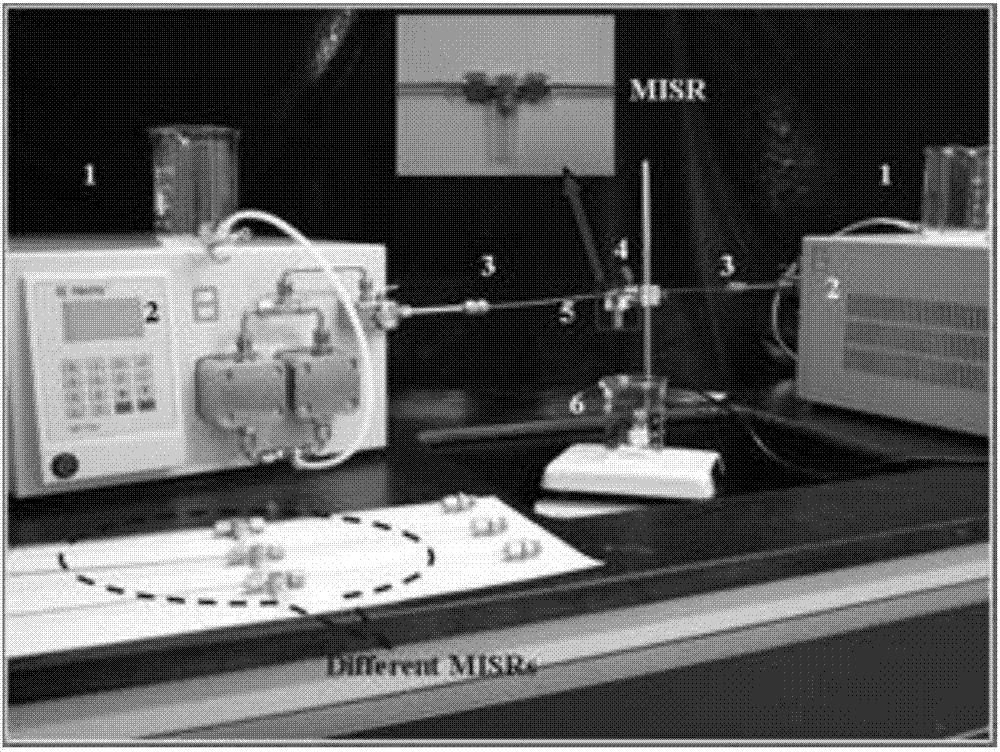

[0033] (2) Turn on the power supply, respectively set the flow rate of the two pumps to 100mL / min, and the pipe diameter of the T-shaped tee to be 0.6mm. as attached figure 1 As shown, the two pumps are started at the same time, and a yellow suspension after the reaction is obtained after impacting the sediment.

[0034] (3) Continue to age the obtained suspension at room temperature for 6 hours, wash with dediluted hydrochloric acid and ionized water for 3-4 times, and dry the precursor at 120° C. for 2 hours.

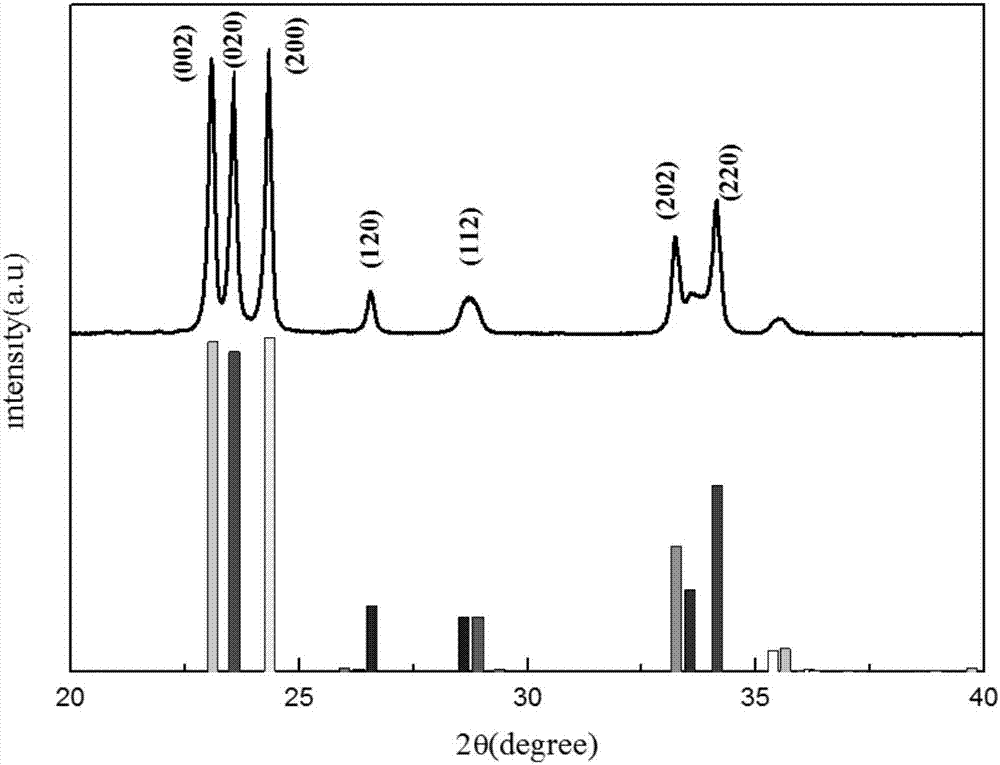

[0035] (4) Grind the dried sample for 10-20min, and calcinate at 600°C for 3h to obtain 30-80...

Embodiment 2

[0038] (1) Weigh 2g of ammonium tungstate and 5mL of acetic acid and dissolve them in deionized water at 60°C, and cool to a constant volume in a 100mL volumetric flask as the reaction solution A. Measure 12.5 mL of concentrated hydrochloric acid, dilute to 100 mL, and prepare 1.5 mol / L hydrochloric acid as reaction solution B.

[0039] (2) Turn on the power supply, set the flow rate of the pumps connecting the two solutions of A and B to 100mL / min, and the pipe diameter of the T-shaped tee to be 0.6mm. as attached figure 1 As shown, the two pumps are started at the same time, and a yellow suspension after the reaction is obtained after impacting the sediment.

[0040] (3) The obtained suspension was aged at room temperature for 6 hours, washed with dilute hydrochloric acid and deionized water for 3-4 times, and the washed precursor was dried at 120° C. for 2 hours.

[0041](4) Grind the dried sample for 10-20min, and calcinate at 600°C for 3h to obtain 30-80nm ultrafine tun...

Embodiment 3

[0044] (1) Weigh 3.29g of Na 2 WO 4 Dissolve 5 mL of acetic acid in deionized water, and prepare 100 mL of 0.1 mol / L sodium tungstate solution as reaction solution A. Measure 12.5 mL of concentrated hydrochloric acid, dilute it to 100 mL with deionized water, prepare 1.5 mol / L hydrochloric acid as reaction solution B, and transfer it into two storage tanks respectively.

[0045] (2) Turn on the power supply, respectively set the flow rate of the two pumps to 100mL / min, and the pipe diameter of the T-shaped tee to be 0.6mm. as attached figure 1 As shown, the two pumps are started at the same time, and a yellow suspension after the reaction is obtained after impacting the sediment.

[0046] (3) Continue to age the obtained suspension at room temperature for 6 hours, wash with dilute hydrochloric acid and deionized water for 3-4 times, and dry the precursor at 120° C. for 2 hours.

[0047] (4) Grind the dried sample for 10-20min, and calcinate at 600°C for 4h to obtain 30-80n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com