Special forced turbulence double-acting reactor for molybdenum disulfide production

A molybdenum disulfide and reactor technology, applied in the field of chemical engineering, can solve the problems of ineffective removal of impurities in the core, long reaction time, incomplete reaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

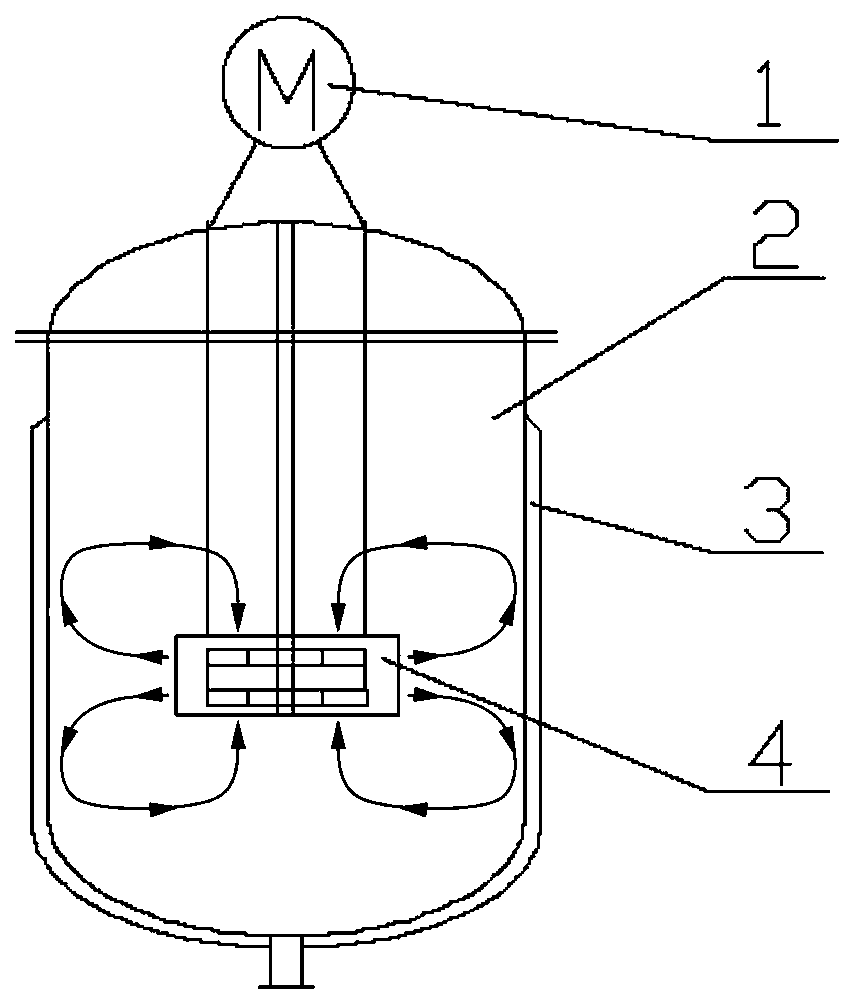

[0022] Such as figure 1 As shown, the special forced turbulent flow double-acting reactor for molybdenum disulfide production of the present invention includes a reactor cylinder 2, a reactor jacket 3 set outside the reactor cylinder 2, and a motor 1 installed on the top of the reactor cylinder 2 , and the emulsification unit 4 driven by the motor 1 hoisted in the reactor cylinder; the emulsification unit 4 is constructed by two unidirectional emulsification machines with the same structure arranged in a porous box in a symmetrical combination.

[0023] The volume of the reactor cylinder 2 described in the present invention is selected according to the production capacity, and the lining material is prepared from enamel material, and the volume is 1000-3000L; Matching, the heat exchange area is 10-15m 2 .

[0024] Furthermore, the power of the motor 1 is mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Heat transfer area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com