Control system for sorting quartz sand

A control system and technology of quartz sand, applied in the field of control system for sorting quartz sand, can solve the problems of mixing, health threat, uneven particle size of quartz sand, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

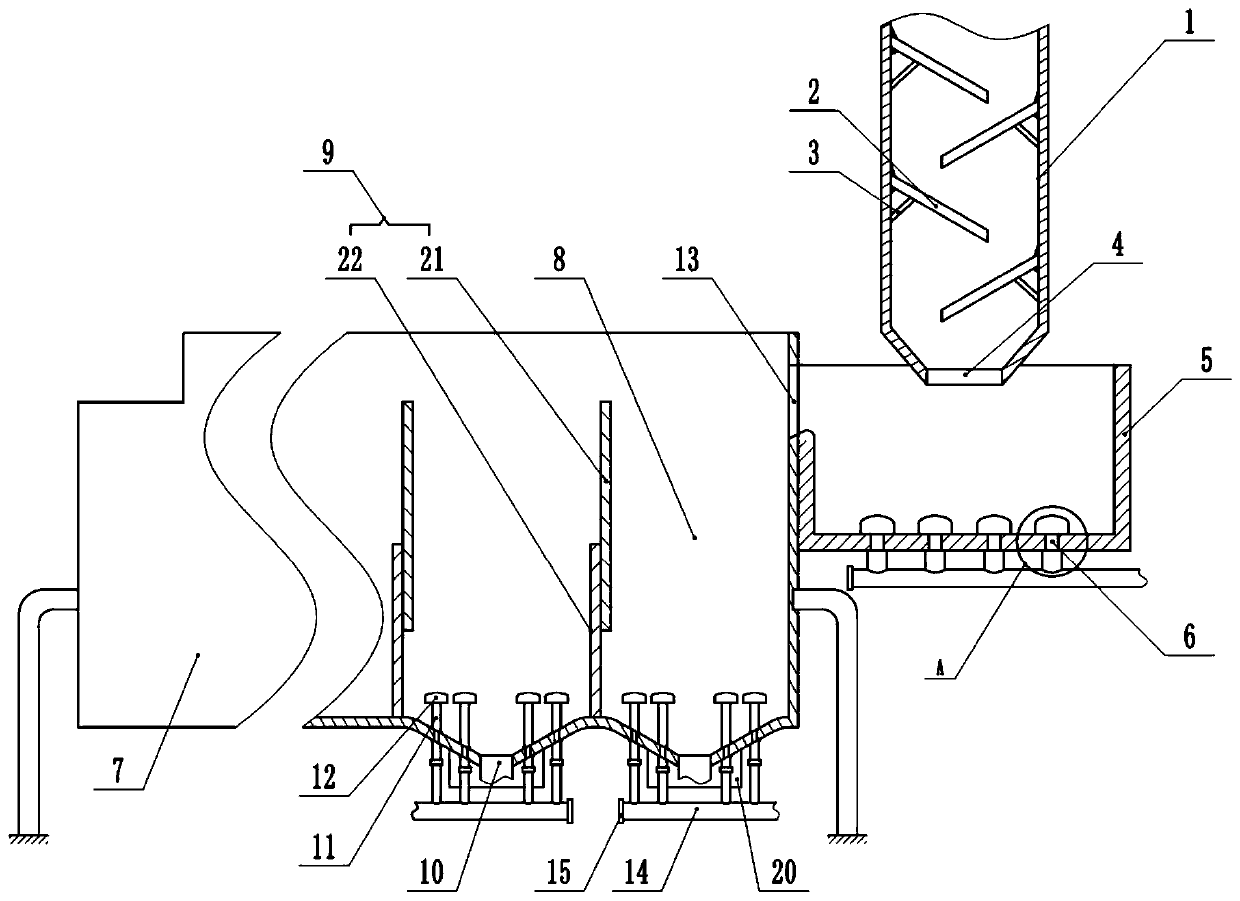

[0049] Embodiment one is basically as attached figure 1 with Image 6 Shown: a control system for sorting quartz sand, including a control terminal, a feeding mechanism and a sorting mechanism, the control terminal includes a controller and an input module, the input module is connected to the controller signal, the input in this embodiment The module is a touch screen, and the touch screen can use the touch screen of Kinco, Siemens or Mitsubishi, and the man-machine interface software adopts the corresponding industrial control configuration software: Kinko MT4000 series, Siemens HMI-TP1500 or Mitsubishi GOT2000 series, and Mitsubishi is used in this embodiment The touch screen and the man-machine interface of Mitsubishi GOT2000 series, and Siemens PLC is used as the controller in this embodiment, the model is S7-400.

[0050] The feeding mechanism includes an overflow box 5 and a feeding box 1 located above the overflow box 5. The upper and lower ends of the feeding box 1 a...

Embodiment 2

[0066] The difference between this embodiment and Embodiment 1 is that the settings of the ultrasonic generator 20 are different, specifically, in combination with figure 1 As shown, the number of sonotrodes 20 is 1 / 2 of the number of sorting chambers, and the bottoms of half of the sorting chambers 8 near the sand inlet 13 sides are correspondingly equipped with sonotrodes 20, and sonotrodes 20 The frequency is set to 33khz. During the implementation process, the sonotrode 20 is started intermittently, and the time interval between each start is 2-4s, and along the flow direction of the sand-water mixture, the start-up time interval of the sonotrode 20 is gradually increased.

[0067] Compared with Embodiment 1, in this embodiment, the frequency of the ultrasonic generators 20 is kept consistent, the number of ultrasonic generators 20 is reduced and the ultrasonic generators 20 are started intermittently, which can save energy to a certain extent. And supersonic generator 20...

Embodiment 3

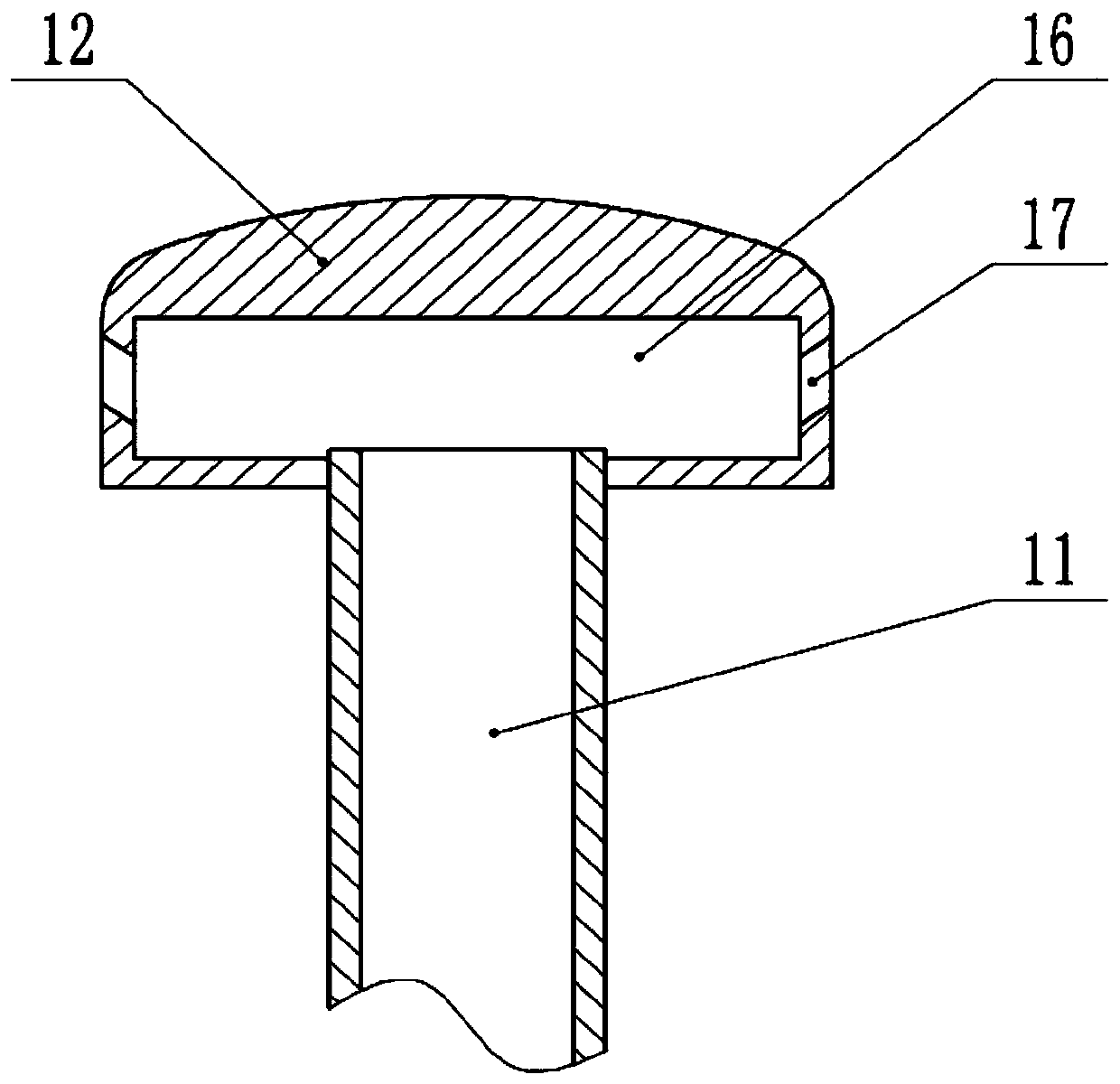

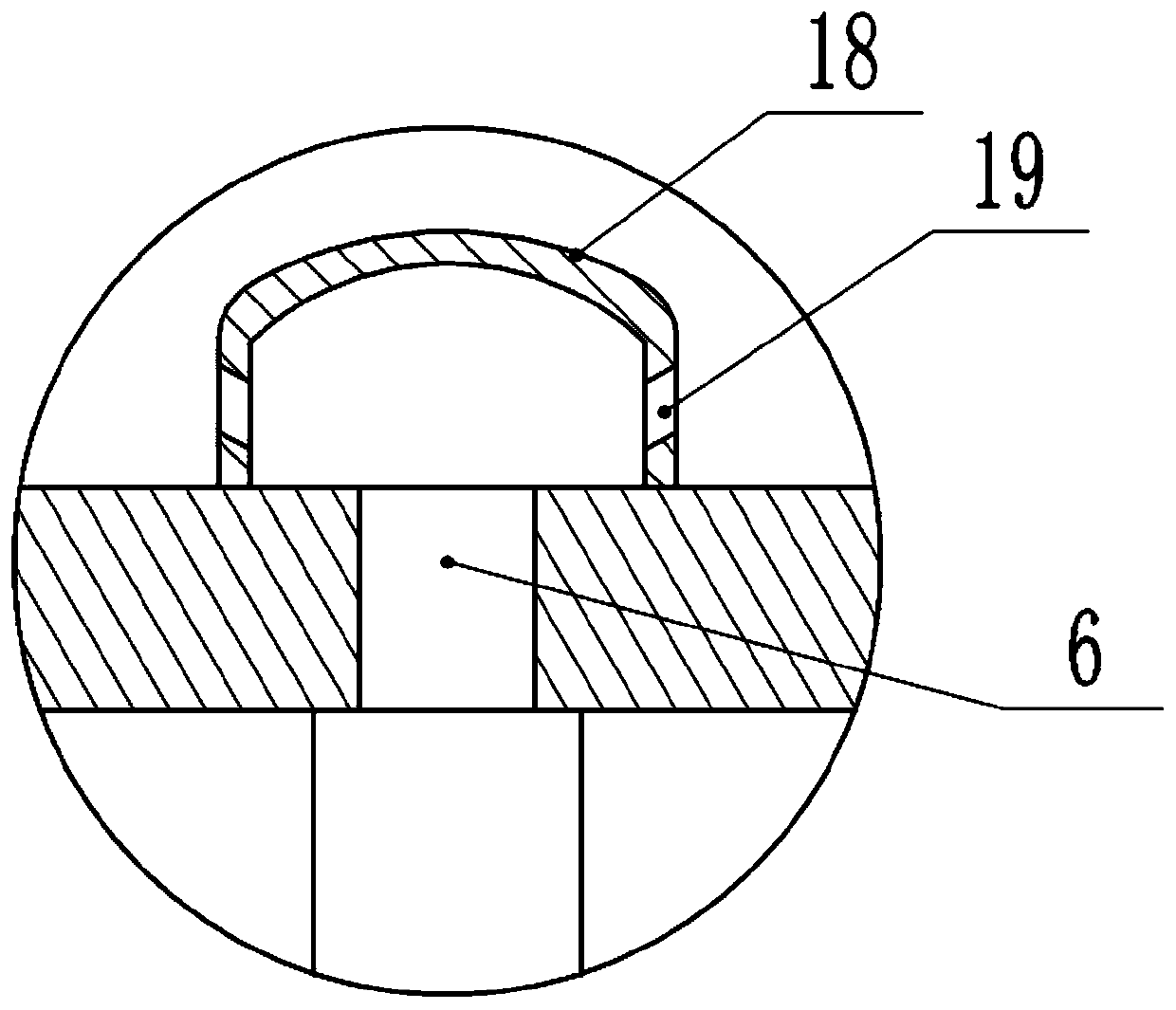

[0071] The difference between this embodiment and embodiment 1 is that the setting of the water supply mechanism is different, specifically, such as Figure 4 with Figure 5 As shown, the water spray part is a water spray plate 12 that is rotatably connected to the upper end of the water supply pipe 11. The water spray holes on the same water spray plate 12 are all inclined in the same direction along the circumference of the water cavity, and the water flow passes through the water cavity 16 from each While the water spray hole 17 is discharging, the water spray plate 12 receives the counterclockwise (or counterclockwise) thrust of the water flow, thereby rotating. A sand cleaning hole is provided at the bottom of the water spray tray 12. In order to reduce the diversion of the sand cleaning hole, only one sand cleaning hole is provided in this embodiment, and a sand cleaning pipe 23 is bonded at the sand cleaning hole. The sand pipe 23 is a rubber pipe, and the outlet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com