Sand-jetting mechanism sand core-molding method using the same

A technology of sand shooting and sand shooting holes, which is applied in the direction of casting molding equipment, molds, cores, etc., can solve the problems affecting the compaction effect of core sand in the core box cavity, so as to reduce loss, ensure compactness, The effect of reducing air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

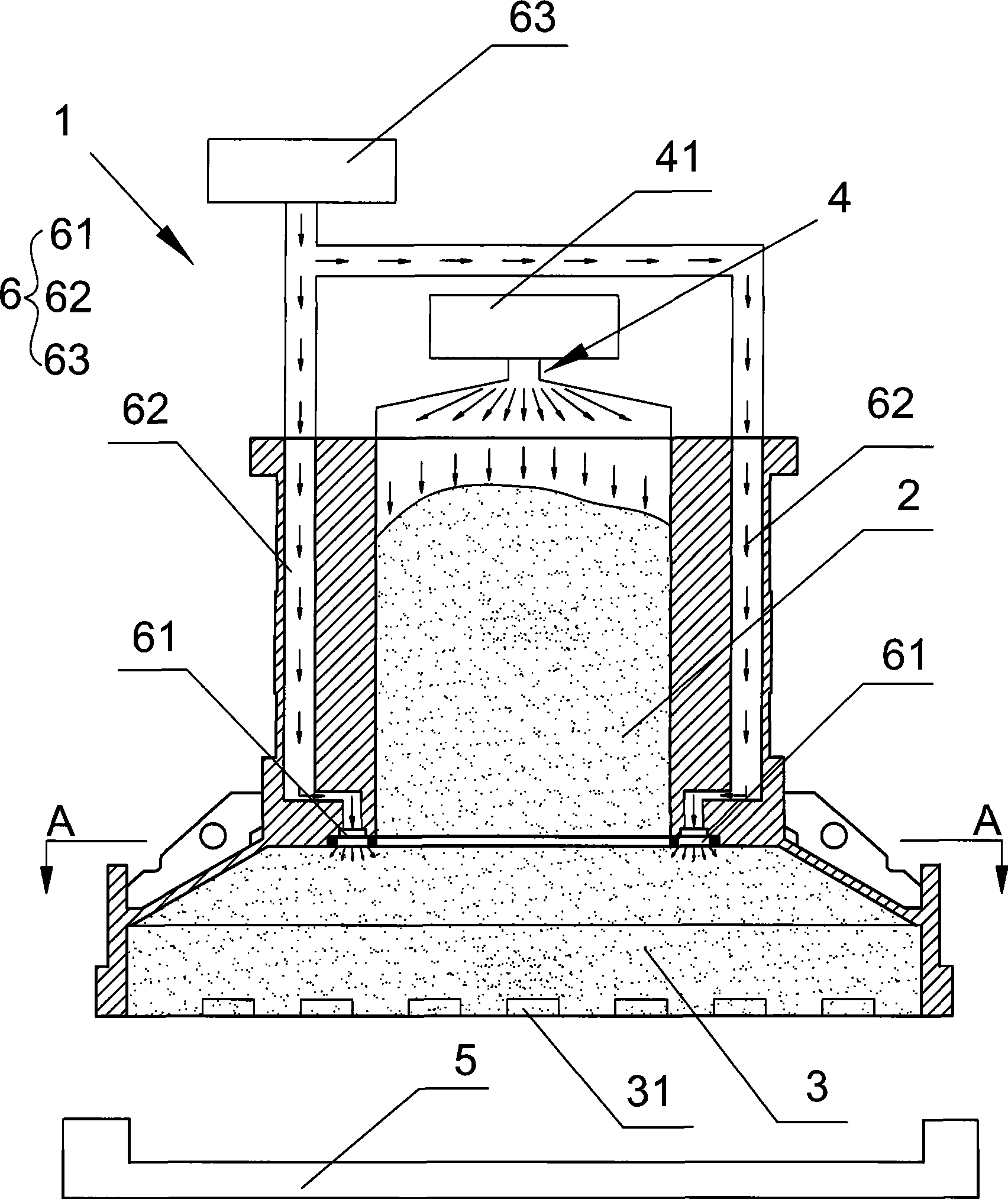

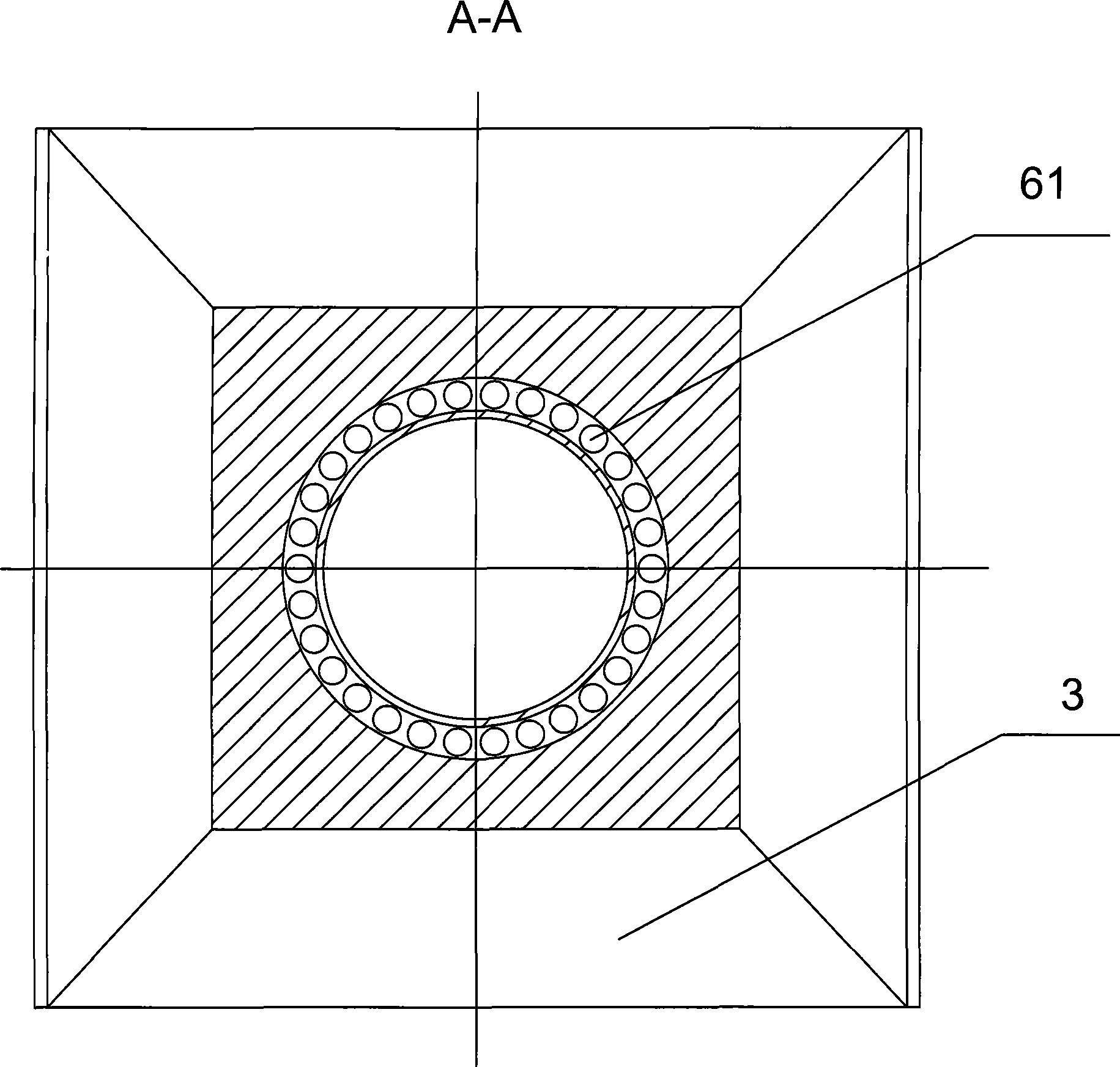

[0014] Such as figure 1 The shown sand shooting mechanism 1 includes a main body sand shooting exhaust mechanism 4, a sand storage cylinder 2 which is arranged below the main body sand shooting exhaust mechanism 4 and stores core sand inside, and is located directly below the sand storage cylinder 2 and on the sand storage cylinder 2. The shot head 3 with a plurality of sand shot holes 31, the main body sand shot exhaust mechanism 4 injects a downward sand shot airflow into the sand storage cylinder 2, the core sand is shot out of the shot head 3 through the sand shot holes 31, and Sand cores are formed in the core box 5 located below the shot head 3 , and the main sand shot exhaust mechanism 4 is connected with a first control valve 41 for controlling the flow rate of the sand shot gas.

[0015] The top of the shooting head 3 is also provided with a shooting head sand-shooting mechanism 6, and the shooting head sand-shooting mechanism 6 injects a downward sand-shooting airflo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com