Safety protection device for bridge pier

A technology for safety protection devices and bridge piers, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of energy dissipation, poor anti-collision effect, limited elastic buffering, short service life, etc., to achieve easy maintenance and repair, Enhanced impact resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

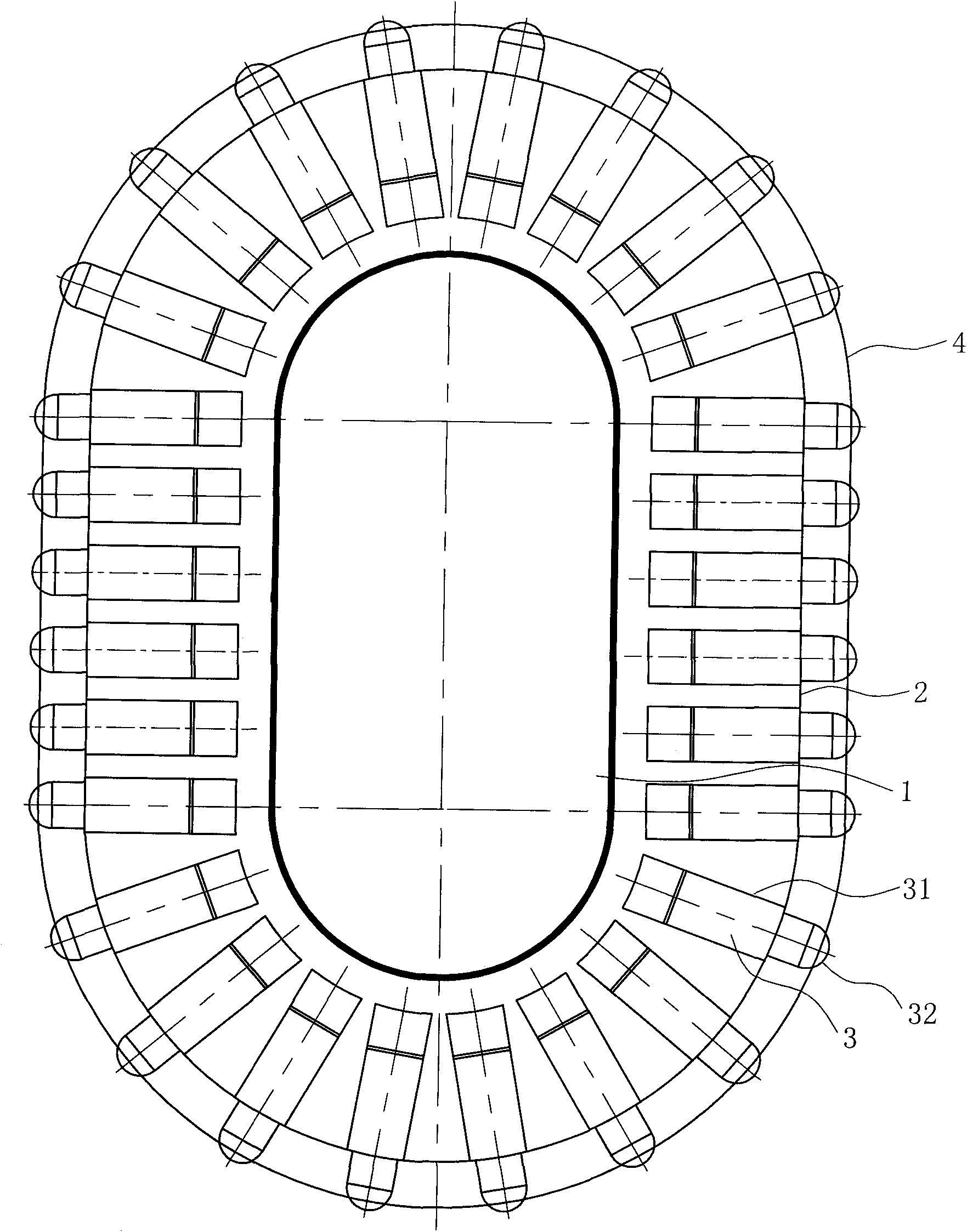

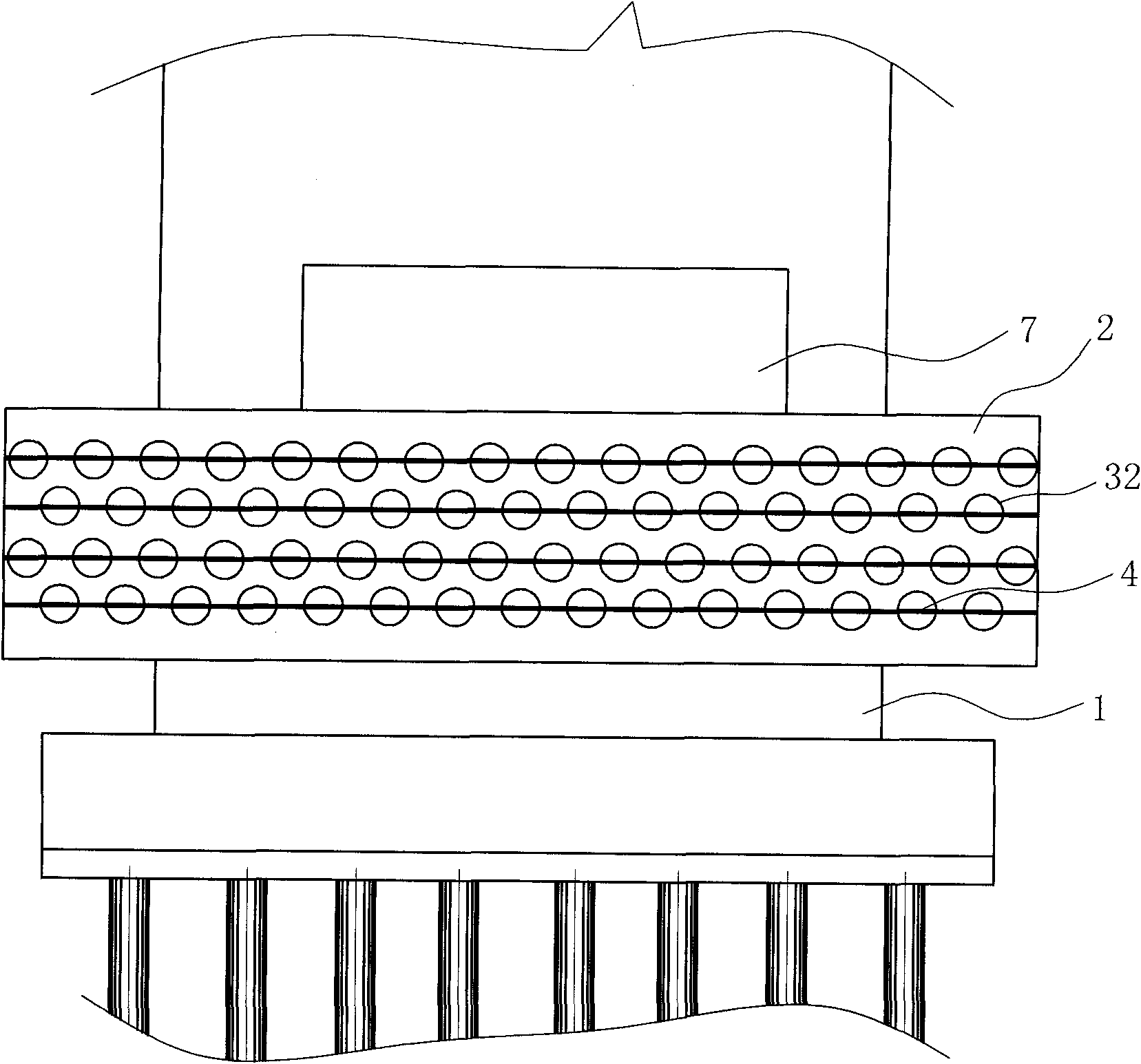

[0028] like figure 1 , figure 2 and image 3 As shown, the safety protection device of the bridge pier includes a steel sleeve box 2 arranged on the periphery of the bridge pier 1 and a hydraulic station 7 fixed on the steel sleeve box 2;

[0029] The steel sleeve box 2 is distributed with upper and lower multi-layer supporting hydraulic cylinders, each layer of supporting hydraulic cylinders includes a plurality of supporting hydraulic cylinders 3 and forms a circle around the pier periphery. In this embodiment, there are four layers in total, see figure 2 shown, while figure 1The distribution of one layer of supporting hydraulic cylinders is shown in the figure, wherein the cylinder body 31 of each supporting hydraulic cylinder 3 is fixed on the steel casing 2, and the head of the piston rod 32 of each supporting hydraulic cylinder 3 is exposed to the steel casing. 2. Outside the outer surface, the heads of the piston rods 32 supporting the hydraulic cylinders of each ...

Embodiment 2

[0032] like Figure 4 As shown, it is the second embodiment of the present invention, and the difference from the first embodiment is that: the steel jacket box 2 is only arranged with multi-layer support hydraulic cylinders on the side close to the waterway, and the steel jacket box 2 is away from Only three supporting hydraulic cylinders 3 are distributed on each layer on that side of the channel, and a plurality of supporting members 5 are also fixed on the surface of the steel jacket box 2 and on the side opposite to the channel. Piece 5 is a hemispherical casting piece, and there are four pieces in each layer.

Embodiment 3

[0034] like Figure 5 As shown, it is the third embodiment of the present invention, and the difference from the first embodiment is that the plurality of supporting hydraulic cylinders 3 are arranged in a circle along the circumferential direction of the steel jacket box 2 in turn to form a radial shape around the pier 1 Structure, a space is left between the inner side of the steel sleeve box 2 and the surface of the bridge pier 1, and a plurality of floating hydraulic cylinders 6 corresponding to the positions of each of the supporting hydraulic cylinders 3 are installed in this space. The supporting hydraulic cylinders 3 and the floating hydraulic cylinders 6 of the layers are distributed symmetrically with the bridge pier 1 as the center, respectively. The blue-shaped gasket 63 is in indirect contact with the surface of the bridge pier 1. The gasket 63 arranged between the head of the piston rod 62 of the floating hydraulic cylinder 6 and the surface of the bridge pier 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com