Metal solid solution modified high-nickel ternary anode material and preparation method thereof

A cathode material and solid solution technology, which is applied in the field of metal solid solution modified high-nickel ternary cathode material and its preparation, can solve the problems of low electrochemical performance and safety performance, unfriendly preparation process, unfavorable production control, etc., and achieves good thermal stability. The effect is that the coating layer is thinner and more uniform, and it is easy for large-scale industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

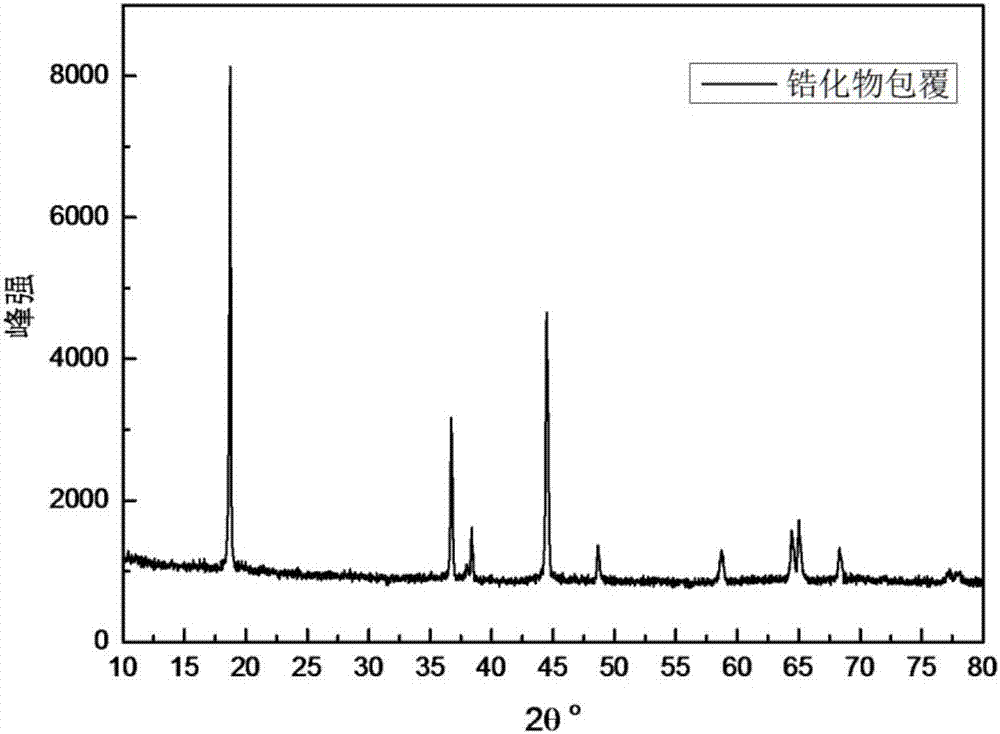

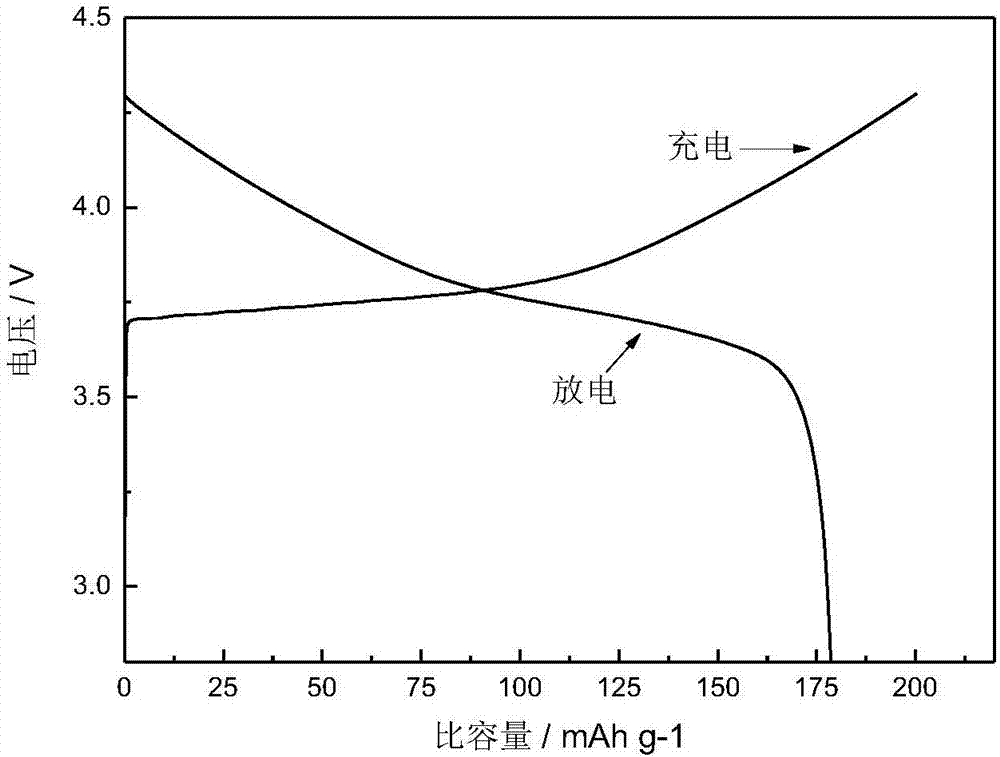

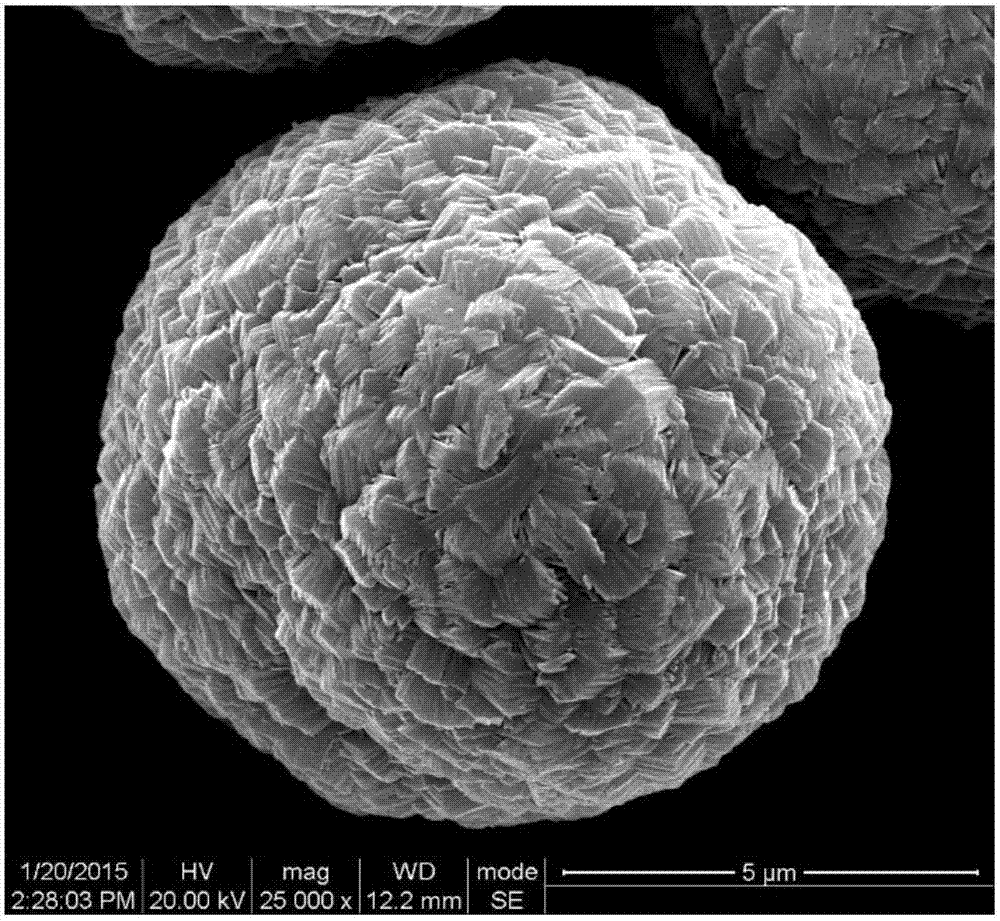

[0035] A method for preparing a metal solid solution modified high-nickel ternary positive electrode material described in this embodiment comprises the following steps:

[0036] (1) Ni 0.6co 0.2 mn 0.2 (OH) 2 (high-nickel ternary positive electrode material precursor) and lithium hydroxide are added to the sand mill tank at a ratio of 1:1.05, and at the same time, zirconium nitrate powder with a mass fraction of 1% of the high-nickel ternary positive electrode material precursor is added;

[0037] (2) Add a certain amount of water to the sand mill tank in step (1), wherein the solid content is about 40%;

[0038] (3) Sand milling and mixing the mixture in step (2), the sand mill speed is 2000r / min, and the stirring time is 2h to obtain a uniformly mixed wet slurry;

[0039] (4) directly put in the corundum boat after drying the wet slurry mixed homogeneously in step (3), carry out calcining with tube furnace, pass into air simultaneously;

[0040] (5) The temperature cur...

Embodiment 2

[0045] A method for preparing a metal solid solution modified high-nickel ternary positive electrode material described in this embodiment comprises the following steps:

[0046] (1) Ni 0.6 co 0.2 mn 0.2 (OH) 2 (precursor of high-nickel ternary cathode material) and lithium hydroxide are added to the ball mill tank at a ratio of 1:1.05, and at the same time, aluminum isopropoxide powder with a mass fraction of 0.5% of the precursor of high-nickel ternary cathode material is added;

[0047] (2) Mix the mixture of step (1) with a ball mill jar, and ball mill for 3 hours at a ball milling speed of 250r / min;

[0048] (3) The uniformly mixed material in step (2) is directly placed in the corundum boat, and calcined in a tube furnace while feeding air;

[0049] (4) The temperature curve set by the tube furnace in step (3) is as follows: set the heating rate to 5°C / min, keep the temperature at 120°C for 1 hour, keep the temperature at 470°C for 3 hours, and keep the temperature a...

Embodiment 3

[0054] A method for preparing a metal solid solution modified high-nickel ternary positive electrode material described in this embodiment comprises the following steps:

[0055] (1) Ni 0.8 co 0.1 al 0.05 (OH) 2 (high-nickel ternary positive electrode material precursor) and lithium hydroxide are added to the sand grinding tank at a ratio of 1:1.05, and at the same time, the mass fraction is 1.0% n-butyl titanate of the high-nickel ternary positive electrode material precursor;

[0056] (2) Add a certain amount of water to the sand mill tank in step (1), wherein the solid content is about 40%;

[0057] (3) Sand milling and mixing the mixture in step (2), the sand mill speed is 2000r / min, and the stirring time is 2h to obtain a uniformly mixed wet slurry;

[0058] (4) directly put in the corundum boat after drying the wet slurry mixed homogeneously in step (3), carry out calcination with tube furnace, pass into oxygen simultaneously;

[0059] (5) The temperature curve set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com