Multifunctional thermal-insulating and heat-preserving phenolic-resin type foam board

A technology of phenolic resin and thermal insulation, which is applied in the field of foam boards, can solve the problems of flammability, generation of poisonous gas, unsuitable application, etc., and achieve the effect of improving mechanical properties and preventing flame spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

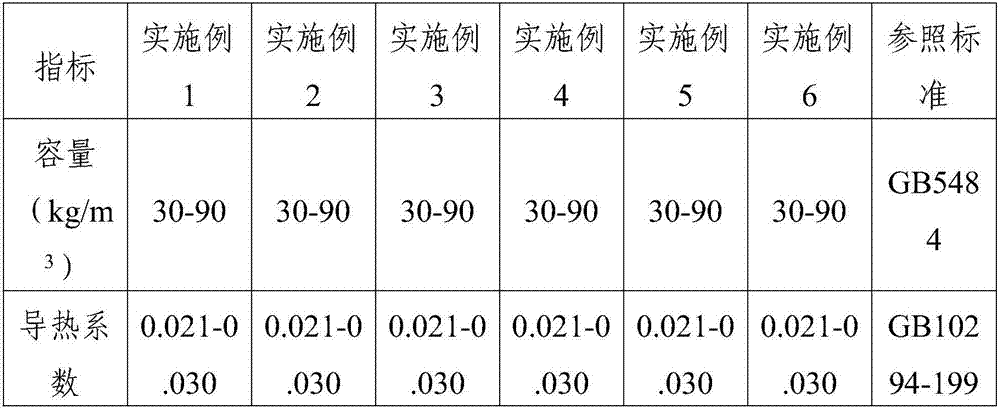

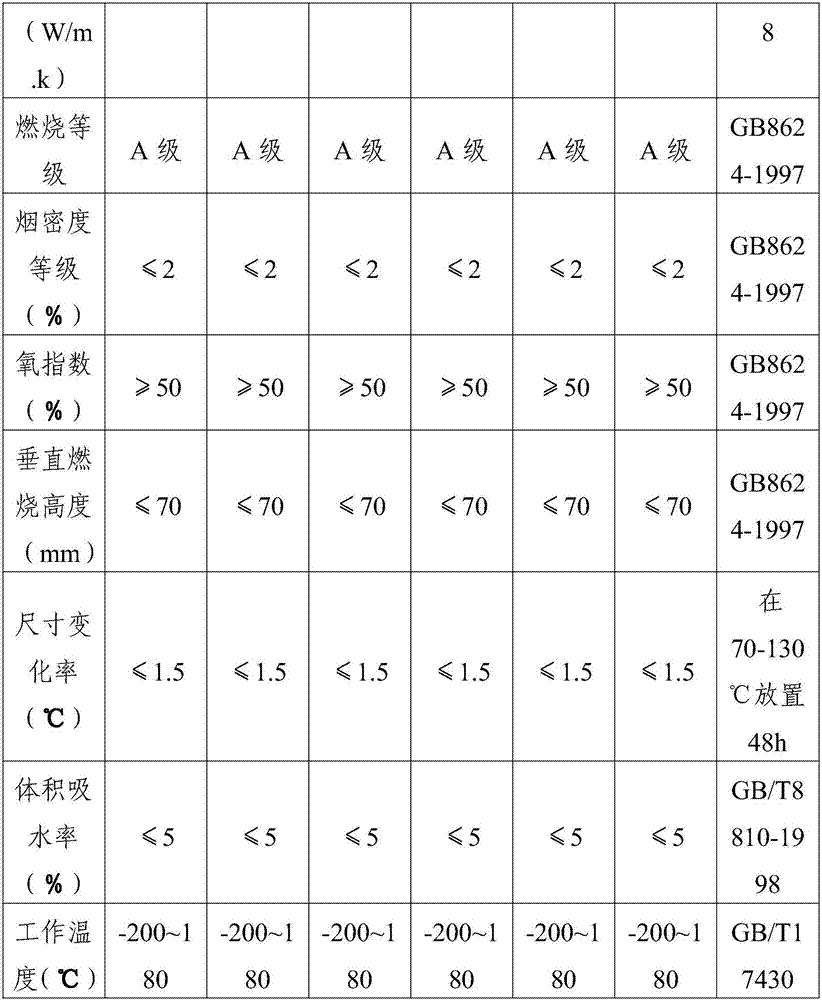

Examples

Embodiment 1

[0021] A multifunctional thermal insulation phenolic resin foam board, which consists of the following raw materials in parts by weight:

[0022] 100 parts of phenolic resin, 13 parts of polyvinyl alcohol and its acetal, 2 parts of cashew nut shell oil, 0.2 part of molybdenum trioxide, 0.1 part of zinc oxide, 1.5 parts of nano-montmorillonite, 1 part of nano-silicon carbide, 0.3 part of boron fiber, 0.5 parts of magnesium hydroxide, 1 part of aluminum hydroxide, 3.5 parts of alkylphenol polyoxyethylene ether surfactants, 0.3 parts of metal soap, 1 part of phosphite, 9 parts of petroleum ether, 0.4 parts of sodium alkylsulfonate, 0.3 parts of pentaerythritol ester, 0.2 parts of phenyl o-hydroxybenzoate, 0.2 parts of silicone, 1.5 parts of bismaleimide, and 10 parts of curing agent.

[0023] Wherein, the curing agent is formed by mixing aliphatic acid anhydride and alicyclic acid anhydride in a mass ratio of 5:1.

Embodiment 2

[0025] A multifunctional thermal insulation phenolic resin foam board, which consists of the following raw materials in parts by weight:

[0026] 75 parts of phenolic resin, 15 parts of nitrile latex, 1 part of cashew nut shell oil, 0.3 part of molybdenum trioxide, 0.2 part of zinc oxide, 1 part of nano-silicon carbide, 1 part of nano-copper, 0.1 part of boron fiber, 1 part of magnesium hydroxide, 1.5 parts of aluminum hydroxide, 3 parts of alkylphenol polyoxyethylene ether surfactants, 0.2 parts of metal soap, 0.5 parts of phosphite, 12 parts of petroleum ether, 0.3 parts of sodium alkylsulfonate, 0.5 parts of pentaerythritol ester, ortho 0.1 part of phenyl hydroxybenzoate, 0.3 part of silicone, 1 part of bismaleimide, 6 parts of curing agent.

[0027] Wherein, the curing agent is formed by mixing aliphatic acid anhydride and alicyclic acid anhydride in a mass ratio of 7:1.

Embodiment 3

[0029] A multifunctional thermal insulation phenolic resin foam board, which consists of the following raw materials in parts by weight:

[0030] 90 parts of phenolic resin, 6 parts of styrene-butadiene latex, 1.5 parts of cashew nut shell liquid, 0.1 part of molybdenum trioxide, 0.2 part of zinc oxide, 2 parts of nano-montmorillonite, 1 part of nano-copper, 0.2 part of boron fiber, 0.7 part of magnesium hydroxide , 0.5 parts of aluminum hydroxide, 5 parts of alkylphenol polyoxyethylene ether surfactants, 0.5 parts of metal soap, 1.5 parts of phosphite, 8 parts of petroleum ether, 0.5 parts of sodium alkylsulfonate, 0.1 part of pentaerythritol ester, 0.5 parts of phenyl o-hydroxybenzoate, 0.2 parts of silicone, 1.2 parts of bismaleimide, and 7 parts of curing agent.

[0031] Wherein, the curing agent is formed by mixing aliphatic acid anhydride and alicyclic acid anhydride in a mass ratio of 9:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com