A kind of second-stage epoxy adhesive layer oil, preparation method and application method thereof

A technology of epoxy viscous oil and viscous oil, applied in the direction of online phenolic epoxy resin adhesives, non-polymer adhesive additives, bridges, etc., can solve complex construction, low temperature stability of cast asphalt, Adhesion problems are not resolved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

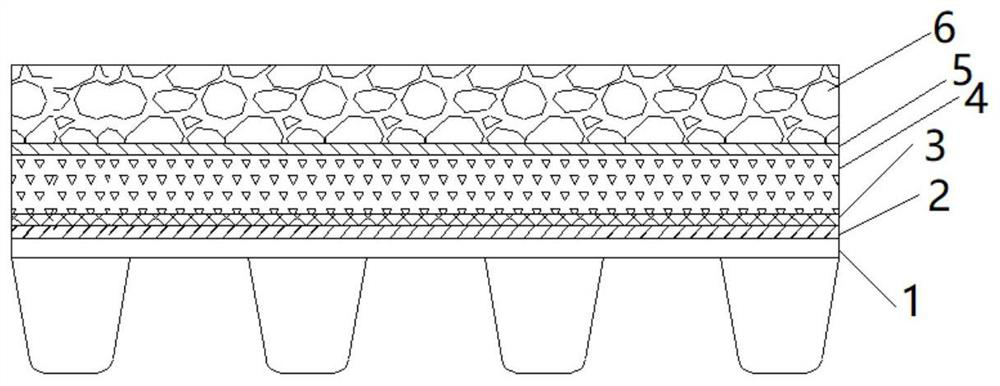

Image

Examples

Embodiment 1

[0041] Put 1 part (molar amount) of hexamethylenediamine into the reactor, and raise the temperature to 80°C; slowly drop 2 parts (molar amount) of butyl glycidyl ether into the reactor, the dropping time is 2 hours, and the material temperature is 80°C, with a stirring rate of 60r / min, to obtain a linear bifunctional secondary amine curing agent; put 1 part (molar amount) of hydrazine hydrate into the reaction kettle, and raise the temperature to 70°C; The isopropanol solution of dimethyl diacid is slowly dropped into the reaction kettle, the dropping time is 2h, and the reaction is continued for 5h after the dropwise addition is completed, the material temperature is 70°C, the stirring speed is 60r / min, and an appropriate amount is added to the reaction kettle Xylene, then distill the azeotrope of xylene, water, hydrazine hydrate and alcohol under vacuum conditions, the organic acid hydrazide obtained is the high melting point latent curing agent;

[0042] Stir 80 parts of n...

Embodiment 2

[0045] Put 1 part (molar amount) of hexamethylenediamine into the reactor, and raise the temperature to 80°C; slowly drop 2 parts (molar amount) of butyl glycidyl ether into the reactor, the dropping time is 2 hours, and the material temperature is 80°C, with a stirring rate of 60r / min, to obtain a linear bifunctional secondary amine curing agent; put 1 part (molar amount) of hydrazine hydrate into the reaction kettle, and raise the temperature to 70°C; The isopropanol solution of dimethyl diacid is slowly dropped into the reaction kettle, the dropping time is 2h, and the reaction is continued for 5h after the dropwise addition is completed, the material temperature is 70°C, the stirring speed is 60r / min, and an appropriate amount is added to the reaction kettle Xylene, then distill the azeotrope of xylene, water, hydrazine hydrate and alcohol under vacuum conditions, the organic acid hydrazide obtained is the high melting point latent curing agent;

[0046] Stir 90 parts of n...

Embodiment 3

[0049] Put 1 part (molar amount) of decyl diamine into the reactor, and raise the temperature to 80°C; slowly drop 2 parts (molar amount) of octyl glycidyl ether into the reactor, the dropping time is 2 hours, and the material temperature is 80°C, with a stirring rate of 60r / min, to obtain a linear difunctional secondary amine curing agent; put 1 part (molar amount) of hydrazine hydrate into the reaction kettle, and raise the temperature to 70°C; The isopropanol solution of diethyl diacid is slowly dripped into the reaction kettle, the dropping time is 2h, and the reaction is continued for 5h after the dropwise addition is completed, the material temperature is 70°C, the stirring speed is 60r / min, and an appropriate amount of Xylene, then distill the azeotrope of xylene, water, hydrazine hydrate and alcohol under vacuum conditions, the organic acid hydrazide obtained is the high melting point latent curing agent;

[0050] Stir 80 parts of novolac polyglycidyl ether, 20 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com