A kind of crystal material, its preparation method and application

A crystal material and crystal technology, applied in the field of inorganic crystal materials, can solve the problems of high repetition frequency, complex structure, large beam divergence angle, etc., and achieve the effect of high power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1Er 6 B 4 o 15 Preparation of small single crystal samples

[0051] Er 2 o 3 and H 3 BO 3 And prepare raw materials according to the following chemical reaction formula:

[0052] 3Er 2 o 3 +4H 3 BO 3 →Er 6 B 4 o 15 +6H 2 O↑

[0053] 99.99% pure Er 2 o 3 with analytically pure H 3 BO 3 Mix evenly, put it into a corundum crucible, put it into a muffle furnace, raise it to the high-temperature solid-phase sintering temperature at a heating rate of 150°C / h, keep it at this temperature for a period of time, and then lower it to room temperature at a certain cooling rate to obtain rod-shaped single crystal sample.

[0054] Table 1 shows the relationship between the number of the obtained samples and the high-temperature solid-state sintering temperature, sintering time, and cooling rate.

[0055] Table 1

[0056] Sample serial number High temperature solid phase sintering temperature High temperature solid state sintering time coo...

Embodiment 2

[0057] Example 2Er 6 B 4 o 15 Preparation of Large Size Single Crystal Samples

[0058] The flux system used was Li 2 O-ZnF 2 -B 2 o 3 , the molar ratio of the three is 1:3:5. Er 2 o 3 and H 3 BO 3 And prepare raw materials according to the following chemical reaction formula:

[0059] 3Er 2 o 3 +4H 3 BO 3 →Er 6 B 4 o 15 +6H 2 O↑

[0060] Flux system and Er 6 B 4 o 15 The mass ratio of the melt is a certain value between 2.9:7 and 3.1:7.

[0061] Weigh Er according to the above ratio 2 o 3 、H 3 BO 3 , Li 2 O and ZnF 2 , after mixing evenly, put it into a Ф60mm×60mm platinum crucible, put it into a self-made crystal growth furnace, slowly raise the temperature to 1050°C at a speed of 150°C / h, keep it for 1h, and then raise the temperature at the same speed until the raw materials are melted, and keep the temperature constant After half an hour, the raw material is completely melted, and then the platinum wire twisted at the bottom is used as the se...

Embodiment 3

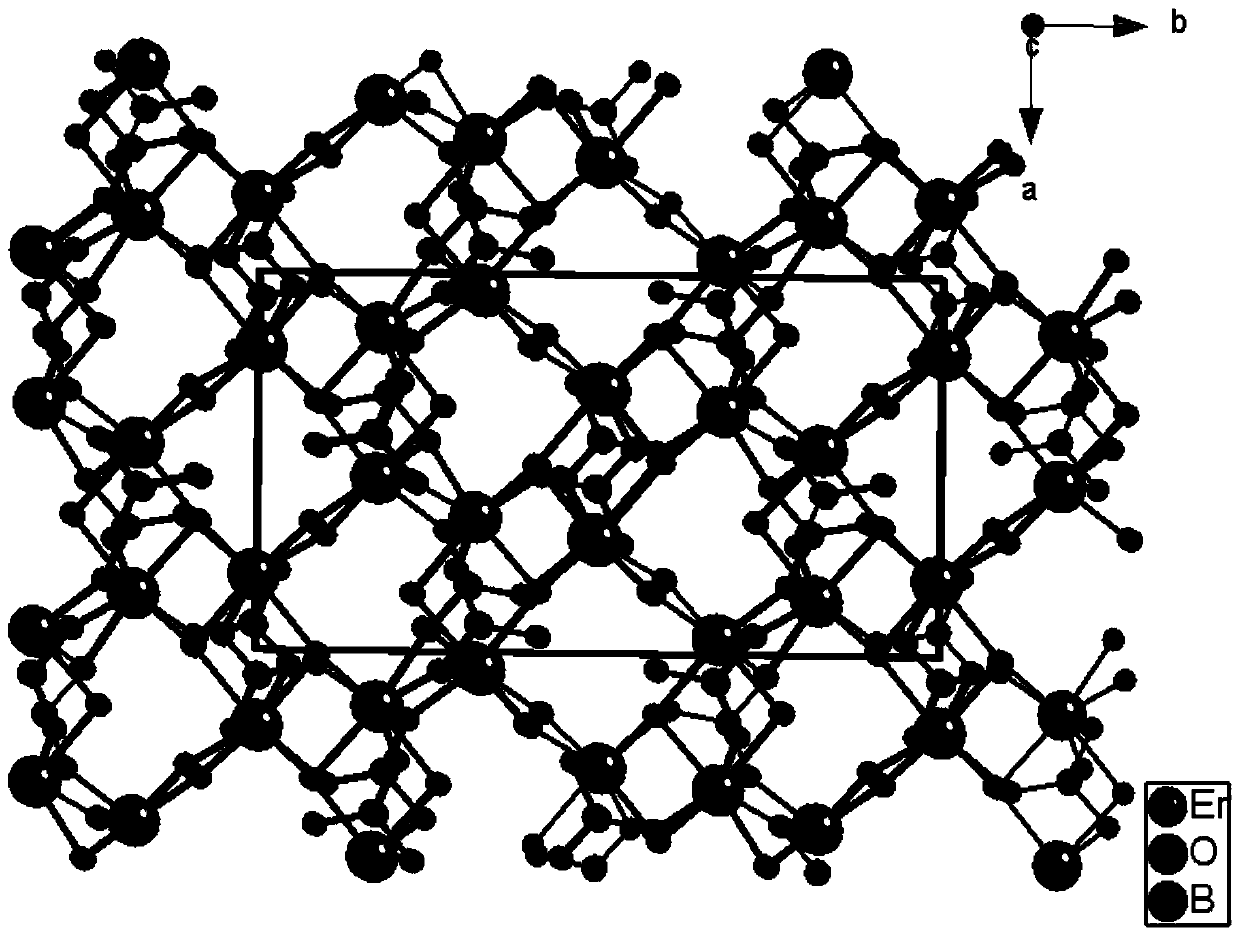

[0065] The crystal structure characterization of embodiment 3 sample

[0066] Take sample S1-1 # Medium size is 0.6×0.45×0.1mm 3 Rod-shaped small single crystal, X-ray single crystal diffraction analysis.

[0067] The results showed that Er 6 B 4 o 15 The crystal belongs to the monoclinic system, space group P2 1 / n(No.14), unit cell parameters β=9 1.899(4)°, Z=4, the density is 7.429g cm -3 . Er 6 B 4 o 15 The crystal structure is as figure 1 Shown by ErO 6 Polyhedra and BO 3 group composition, each ErO 6 with the other two ErO 6 and two BOs 3 The units are connected to form a sandwich layer structure, and the layers are filled with BO formed by B atoms and three O atoms. 3 Triangular group, B-O bond length is The O-B-O bond angle is 120.000(1)°.

[0068] Sample S1-1 was analyzed by powder X-ray diffraction method # ~S1-3 # , S2 # ~S5 # structure was determined. Sample S1-1 # The theoretical XRD diffraction pattern obtained from the crystal structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com