Coating large-area continuous deposition and surface modifying method

A surface modification, large-area technology, applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

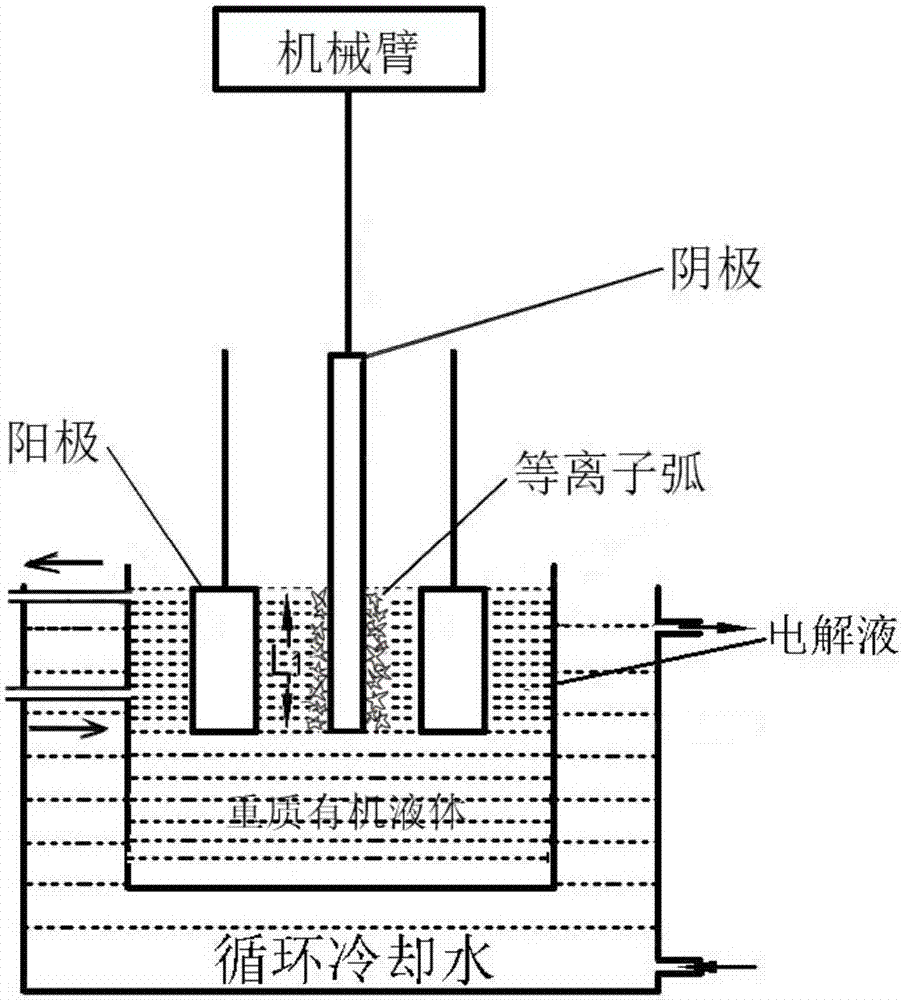

[0022] use figure 1 In the electrolytic cell with the double-layer solution distribution structure shown, the cathode is moved longitudinally at a constant rate to carry out the cathode plasma electrodeposition coating under the condition that the area ratio of the anode and the cathode is kept constant (greater than 2). The upper electrolyte was 30 g / L NiSO 4 ·6H 2 O aqueous solution is the basic electrolyte, add 20g / L polyethylene glycol, and add 20ml / LH 2 SO 4The electrolyte is acidic, and the organic solution in the lower layer is a tetrachlorethylene solution. The 6061 aluminum alloy of 100mm×10mm×1.5mm is used as the cathode, and the platinum sheet is used as the anode. The pulse power supply is used with a frequency of 2000Hz and a duty cycle of 90%. The electrolysis voltage is always controlled at a voltage higher than the arc starting voltage of 20V. The thickness of the electrolyte layer in the upper layer of the tank is controlled at about 15 mm, and the cathode...

Embodiment 2

[0024] use figure 1 In the electrolytic cell with the double-layer solution distribution structure shown, the cathode is moved longitudinally at a constant rate to perform the cathode plasma electrolytic nitriding treatment under the condition that the area ratio of the anode and the cathode remains unchanged (greater than 2). The upper electrolyte uses a solution with a weight ratio of urea to water of 1:2 as the basic electrolyte for nitriding, where the concentration of urea is 0.33 g / ml, and 0.013 g / ml NH 4 Cl is used as a conductive agent, 10g / L polyethylene glycol is added, and the organic solution of the lower floor is a tetrachlorethylene solution. The Q235 carbon steel material is used as the cathode, and the platinum sheet is used as the anode. Using DC power supply, the electrolysis voltage is always controlled at a voltage 30V higher than the arcing voltage, the thickness of the aqueous electrolyte layer on the upper layer of the electrolytic cell is controlled at...

Embodiment 3

[0026] use figure 1 In the electrolytic cell with the double-layer solution distribution structure shown, the cathode is moved longitudinally at a constant rate to carry out the cathode plasma electrodeposition coating under the condition that the area ratio of the anode and the cathode is kept constant (greater than 2). The upper electrolyte is 0.8 mol / l Al(NO 3 ) 3 The aqueous solution is used as the basic electrolyte, 15g / L polyethylene glycol is added, and the organic solution in the lower layer is a tetrachlorethylene solution. The NiCrAlY alloy is used as the cathode, and the platinum sheet is used as the anode. Using a pulse power supply, the frequency is 500Hz, the duty cycle is 60%, the electrolysis voltage is always controlled at a voltage 50V higher than the arcing voltage, the thickness of the electrolyte layer in the upper aqueous solution of the electrolytic cell is controlled at about 15mm, and the vertical direction of the cathode is 0.05mm / s After the depos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com