A kind of centrifugal spinning preparation method of silica/polystyrene micro/nano fiber membrane

A nanofiber membrane and centrifugal spinning technology, applied in spinning solution preparation, fiber treatment, rayon manufacturing, etc., can solve problems such as pollution, low production efficiency, complex design control technology, etc., and achieve easy reaction conditions and anti-aging The effect of improved performance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

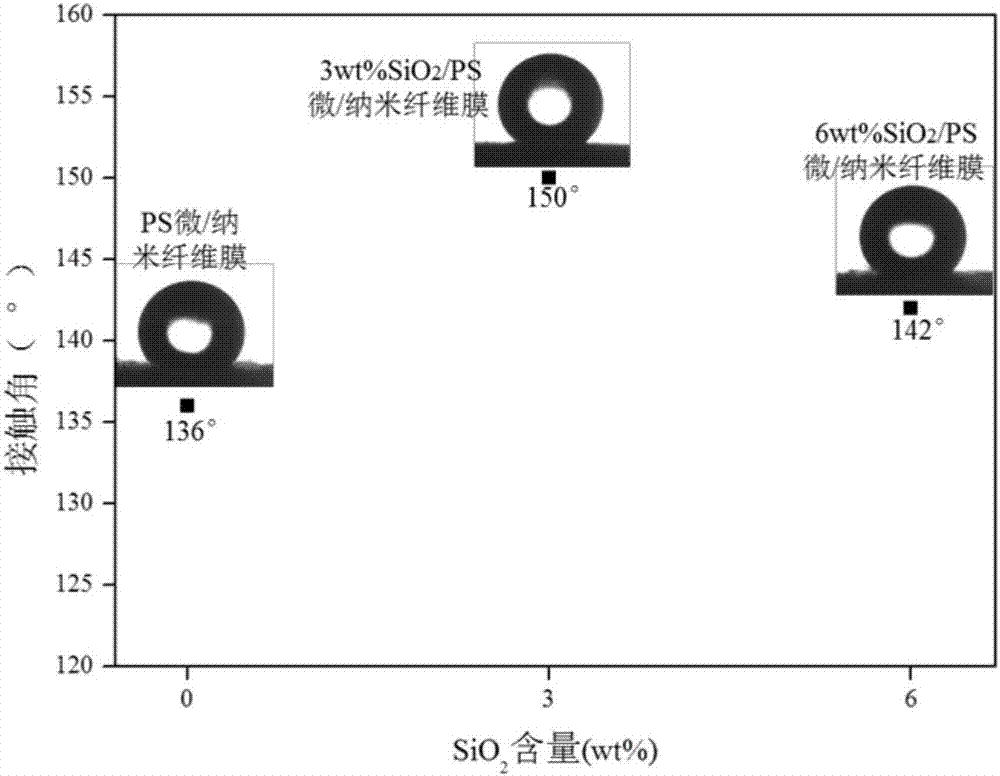

Embodiment 1

[0031] (1) Accurately weigh 1.8g polystyrene (PS) (wherein the molar mass M=260000g / mol of PS) with an analytical balance and place it in a 20ml sample bottle, add 8.2g N-N dimethylformamide (DMF) dropwise, The sample bottle was sealed with raw material tape, heated to 60°C, and stirred for 24 hours to finally obtain a centrifugal spinning solution with evenly dispersed PS.

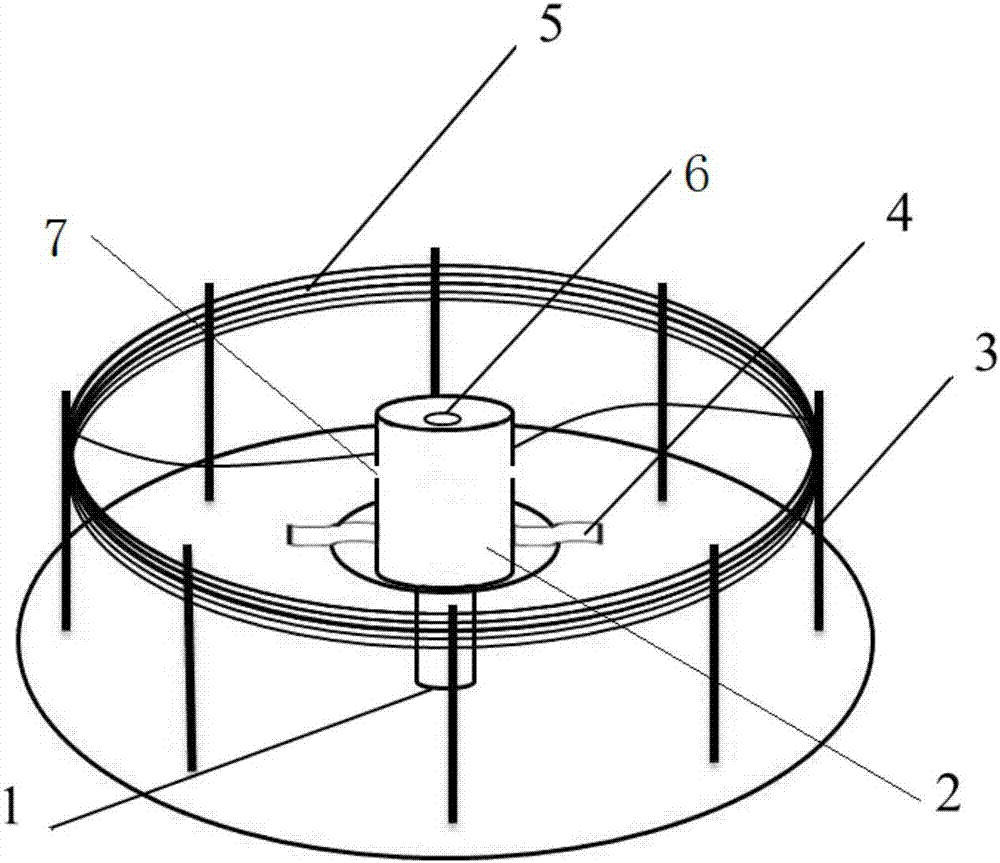

[0032] (2) adopt figure 1The centrifugal spinning device shown is used for centrifugal spinning, the set speed is 8000rpm / min, the distance between the collecting rods is 10cm, and the diameter of the spinneret holes is 0.4mm. Take 5ml of the spinning solution sample in the spinning head, turn on the motor, and pass through the collecting rods. A polystyrene (PS) micro / nanofibrous membrane was obtained.

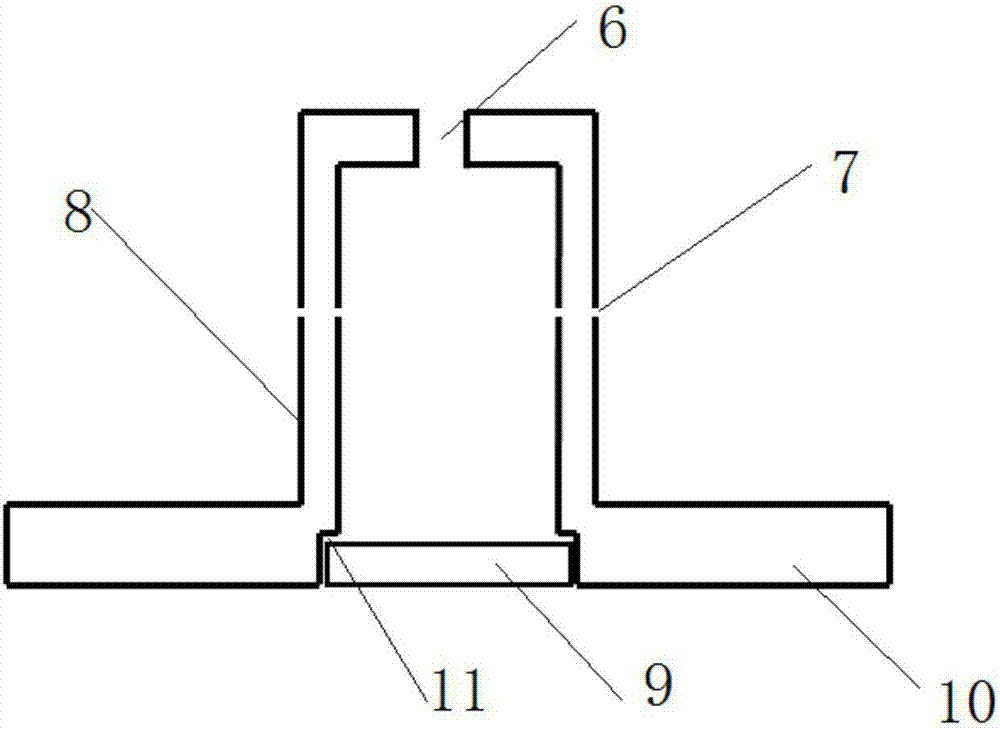

[0033] The centrifugal spinning device used in centrifugal spinning is as follows: figure 1 with image 3 As shown, it includes a motor 1, a spinning head 2 and a collecting rod 3. The spinning head i...

Embodiment 2

[0040] (1) Use a pipette to accurately pipette 5ml of ethyl orthosilicate, dissolve it in 35ml of absolute ethanol and 2ml of deionized water, add 3ml of ammonia water dropwise, react at 25°C for 2 hours to form a silica sol, and then drop Add 1g of methacryloxytrimethoxysilane (MPS), react at 25°C for 24 hours, repeat centrifugal dispersion 6 times (absolute ethanol is used as the dispersant), and dry at 60°C for 8 hours to obtain Hydrophobic silica with a particle size of 250-300nm is desired.

[0041] (2) Accurately weigh 1.8g polystyrene (PS) and the silicon dioxide prepared by 0.3g step (1) with an analytical balance, (wherein the molar mass M=260000g / mol of PS) is placed in a 20ml sample bottle, Add 7.9g of N-N dimethylformamide (DMF) dropwise, seal the sample bottle with raw material tape, heat to 60°C, and stir for 24 hours to finally obtain SiO 2 , PS uniformly dispersed centrifugal spinning solution.

[0042] (3) adopt figure 1 The centrifugal spinning device show...

Embodiment 3

[0044] (1) Use a pipette to accurately pipette 5ml of ethyl orthosilicate, dissolve it in 35ml of absolute ethanol and 2ml of deionized water, add 3ml of ammonia water dropwise, react at 25°C for 2 hours to form a silica sol, and then drop Add 1g of methacryloxytrimethoxysilane (MPS), react at 25°C for 24 hours, repeat centrifugal dispersion 6 times (absolute ethanol is used as the dispersant), and dry at 60°C for 8 hours to obtain Hydrophobic silica with a particle size of 250-300nm is desired.

[0045] (2) Accurately weigh 1.8g polystyrene (PS) and the silicon dioxide prepared by 0.6g step (1) with an analytical balance, (wherein the molar mass M=260000g / mol of PS) is placed in a 20ml sample bottle, Add 7.6g of N-N dimethylformamide (DMF) dropwise, seal the sample bottle with raw material tape, heat to 60°C, and stir for 24 hours to finally obtain SiO 2 , PS uniformly dispersed centrifugal spinning solution.

[0046] (3) adopt figure 1 The centrifugal spinning device show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com