A kind of strontium-containing biological material and its preparation method and application

A biomaterial and composite biomaterial technology, applied in the field of biomaterials, can solve the problems of poor cell ALP activity, changing the chemical stability of materials, and poor cell osteogenic differentiation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: high temperature solid state method prepares Sr 2 ZnSi 2 o 7

[0051] SiO 2 :ZnO:SrCO 3 Weigh according to molar ratio 2:1:2, mix into powder, place in agate jar, add agate ball and alcohol respectively according to powder: agate ball: alcohol mass ratio of 1:1.5:1, and the proportion of agate ball is the largest (10mm diameter): medium (8mm diameter): small (5mm diameter) is equal to 2:2:1, ball milling in a planetary ball mill at 300r / min for 4h;

[0052] The ball-milled powder was dried in an oven at 120°C, and then calcined in a muffle furnace at 1250°C for 4 hours;

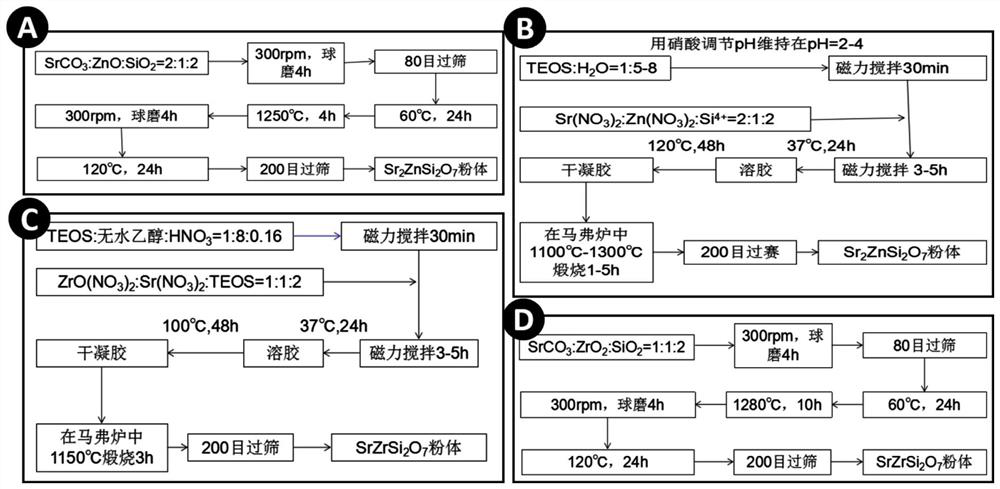

[0053] Continue to ball mill the sintered powder at 300r / min for 4 hours; dry the ball milled powder in an oven at 120°C, and pass through a 200-mesh sieve to obtain Sr 2 ZnSi 2 o 7 , see the preparation flow chart figure 2 A in

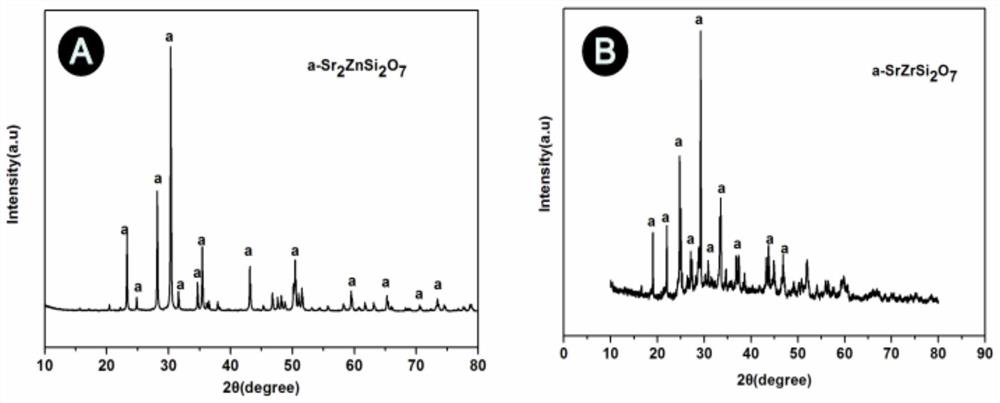

[0054] The prepared Sr 2 ZnSi 2 o 7 Carry out X-ray diffraction, the result shows that it is a tetragonal crystal system, see figure 1 A in, and ...

Embodiment 2

[0055] Example 2: Preparation of SrZrSi by high-temperature solid-phase method 2 o 7

[0056] Weigh SiO2:ZrO2:SrCO3 at a molar ratio of 2:1:1, mix it into powder, place it in an agate jar, add agate balls and alcohol respectively according to the mass ratio of powder: agate ball:alcohol at 1:1.5:1, wherein The proportion of balls is large: medium: small equal to 2:2:1, and the ball is milled in a planetary ball mill at 300r / min for 4h;

[0057] The ball-milled powder was dried in an oven at 120°C, and then calcined in a muffle furnace at 1280°C for 10 hours;

[0058] Continue to ball mill the sintered powder at 300r / min for 4 hours; dry the ball milled powder in an oven at 120°C, and pass through a 200-mesh sieve to obtain SrZrSi 2 o 7 , see the preparation flow chart figure 2 D in

[0059] The prepared SrZrSi 2 o 7 Carry out X-ray diffraction, the result shows that it is monoclinic, see figure 1 B in, and X-ray diffraction results are consistent with SrZrSi 2 o 7 Th...

Embodiment 3

[0060] Embodiment 3: sol-gel prepares Sr 2 ZnSi 2 o 7

[0061] Mix tetraethyl orthosilicate (TEOS) with water at a molar ratio of 1:(5-8), adjust the pH to 2-4 with nitric acid, and stir thoroughly at room temperature for 30 minutes; add zinc nitrate tetrahydrate and strontium nitrate, in which Sr(NO 3 ) 2 :Zn(NO 3 ) 2 : The molar ratio of TEOS is 2:1:2, magnetic stirring for 3-5h;

[0062] Airtight aging at room temperature overnight to form a sol; heat the sol in an oven at 120°C for 48 hours to form a xerogel; place the xerogel in a muffle furnace for calcination at 1100-1300°C for 3-5 hours; sieve the calcined powder , get Sr 2 ZnSi 2 o 7 , see the preparation flow chart figure 2 B in

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com