A method of growing highly adhesive silver metal pattern on the surface of polyimide film

A technology of polyimide film and high adhesion, applied in metal material coating process, coating, liquid chemical plating, etc. Problems such as patterning and low metal utilization efficiency, to achieve the effect of facilitating industrial production, simple and fast method, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A: the polyamic acid (PAA) solution of the BPDA-ODA system with a solid content of 12% is cast into a film, and placed in a fume hood for 24 to 36h to dry to obtain the semi-dry PAA film of the BPDA-ODA system;

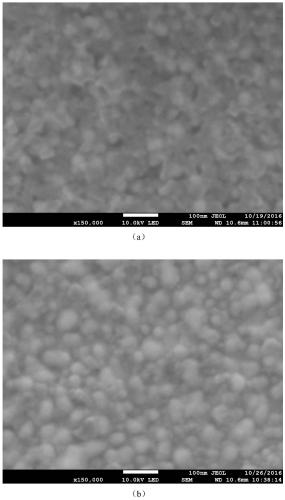

[0036] B: AgNO 3 , water, glycerol and ethanol are mixed according to mass ratio (a) 6:4:7:2 and (b) 8:4:7:2 respectively under 20 ℃, and after fully stirring, silver colloids with different silver contents are obtained;

[0037] C: Apply the silver colloid obtained in step B to the surface of the PAA membrane obtained in step A at 20°C according to the pre-designed pattern for ion exchange for 20 minutes. Then rinse with deionized water to obtain a polyamic acid film containing silver ions in the superficial layer;

[0038] D: Put the polyamic acid film containing silver ions obtained in step C into a high-temperature oven for heat-induced reduction, the final temperature is 300 ° C, and the time is 4 hours, so as to prepare a silver-coated polyimide film wit...

Embodiment 2

[0041] A: the polyamic acid (PAA) solution of the BPDA-ODA system with a solid content of 15% is cast into a film, and placed in a fume hood for 24 to 36h to dry to obtain the semi-dry PAA film of the BPDA-ODA system;

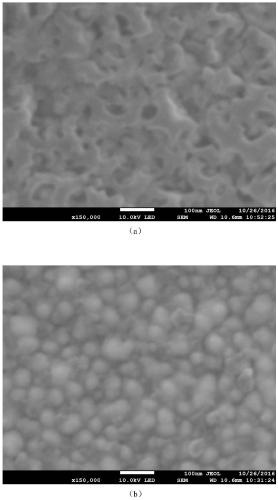

[0042] B: AgNO 3 , water, glycerol and ethanol are mixed according to the mass ratio of 7:4:8:2 at 30°C, and the silver colloid is obtained after fully stirring;

[0043] C: Apply the silver colloid obtained in step B to the surface of the PAA membrane obtained in step A at 30°C according to a pre-designed pattern for ion exchange, and the time is (a) 20min and (b) 40min respectively. Then rinse with deionized water to obtain a polyamic acid film containing silver ions in the superficial layer;

[0044] D: Put the silver-ion-containing polyamic acid film obtained in step C into a high-temperature oven for heat-induced reduction, the final temperature is 350°C, and the time is 4 hours, so as to prepare a surface-patterned silver-coated polyimide film .

[004...

Embodiment 3

[0047] A: the polyamic acid (PAA) solution of the BPDA-ODA system with a solid content of 12% is cast into a film, and placed in a fume hood for 24 to 36h to dry to obtain the semi-dry PAA film of the BPDA-ODA system;

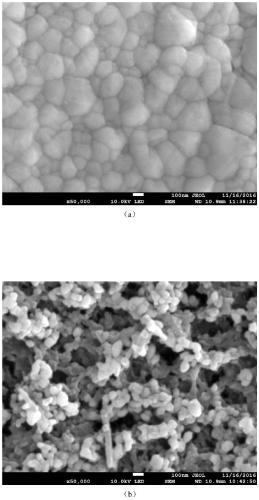

[0048] B: AgNO 3 , water, glycerol, ethylene glycol and ethanol are mixed according to the mass ratio of 8:6:4:3:2 at 30°C, and the silver colloid is obtained after fully stirring;

[0049] C: Apply the silver colloid obtained in step B to the surface of the PAA film obtained in step A at 30°C according to the pre-designed pattern for ion exchange for 30 minutes. Then rinse with deionized water to obtain a polyamic acid film containing silver ions in the superficial layer;

[0050] D: apply (a) 0.02mol / L DMAB or (b) 0.1mol / L alkaline glucose solution at 30°C to the surface of the polyamic acid membrane containing silver ions obtained in step C for 30min. Then rinse with deionized water;

[0051] E: Put the polyamic acid film containing silver ions obtained i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com