Supercritical electronic injection flash boiler

A flash boiler, supercritical technology, applied in steam generation, steam engine installations, machines/engines, etc., can solve problems such as non-conformance, large boiler size, simple understanding, etc., to increase safety, expand heat exchange area, improve The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

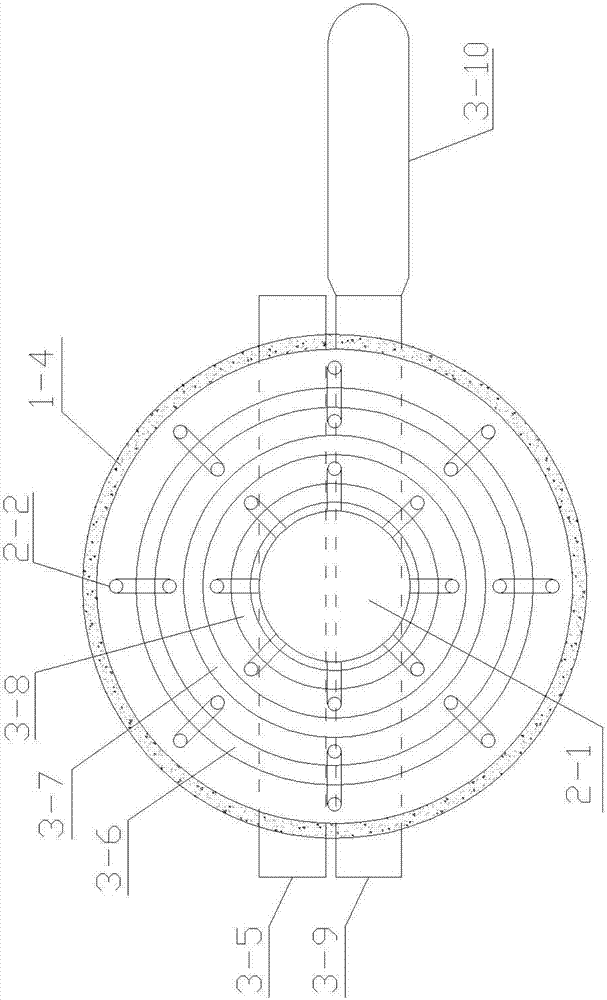

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation.

[0033] The structure of the supercritical EFI flash boiler of the present invention is as follows figure 1 , figure 2 As shown, the supercritical EFI flash boiler consists of molten salt feeding pipe 1-1, molten salt tank 1-2, molten salt discharge pipe 1-3, insulation layer 1-4, combustion chamber 2-1, and flue gas pipe 2 -2, flue gas chamber 2-3, burner 2-4, waste heat recovery water tank 3-1, outlet pipe 3-2, high-pressure plunger pump 3-3, high-pressure spray device 3-4, steam generator 3-5 , the first steam coil 3-6, the second steam coil 3-7, the third steam coil 3-8, the steam tank 3-9, the cylinder 3-10, the smoke exhaust pipe 3-11, the water inlet pipe 3 -12. First flue gas tank 3-13, second flue gas tank 3-14, air pipe 3-15, water tank 3-16, steam turbine 4-1, generator 4-2, first electric heater 4- 3 and the second electric he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com