A method for recovering iron from high-iron red mud

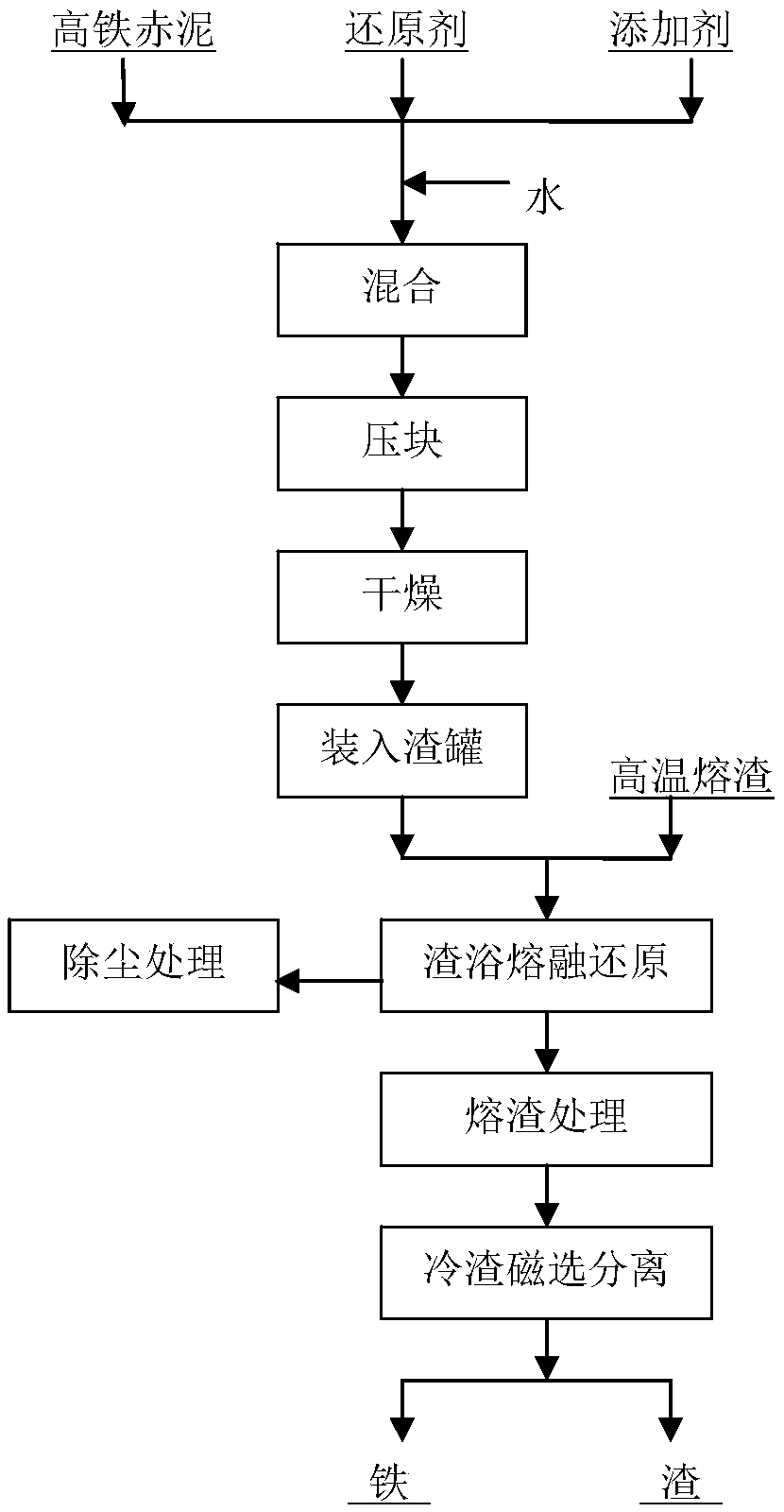

A technology of high-iron red mud and iron recovery, which is applied in the treatment of iron recovery from red mud, and in the field of high-temperature metallurgical slag treatment of high-iron red mud recovery iron, which can solve the problems of complicated process operation, difficult heat recovery and utilization, and low recovery rate. , to achieve the effect of good reaction thermodynamic conditions and kinetic conditions, large-scale comprehensive utilization, and rapid smelting reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Use a mixer to mix high-iron red mud, coke powder, and calcium ferrite powder in proportion and stir evenly, then use a ball press to make a 10-30mm red mud agglomerate, and wait until the agglomerate is dried to a moisture content of ≤3% for later use. The proportion of calcium ferrite powder is 3.5wt%, and the rest is high-iron red mud and coal powder. The molar ratio of fixed carbon content in coal powder to oxygen content of iron oxide in high-iron red mud is C / O=1.25. The chemical composition of high-iron red mud in this embodiment is mainly: Fe 2 o 3 65.2wt%, Al 2 o 3 8.1wt%, Na 2 O is 2.4wt%, the rest is SiO 2 , CaO and other impurities; the fixed carbon content of the coke powder is 85.6wt%, the sulfur content is 0.9wt%; the calcium ferrite content in the additive is 95.5wt%.

[0029]Put 1.5t of red mud lumps into the empty slag tank (about 32t of slag capacity) in the steelmaking work area, and then inject the steelmaking slag into the slag when the slag i...

Embodiment 2

[0031] Use a mixer to mix high-iron red mud, coal powder, and calcium ferrite powder in proportion and stir evenly, then use a briquetting machine to make a 10-30mm red mud agglomerate, and wait until the agglomerate is dried to a moisture content of ≤3% for later use. The proportion of calcium ferrite powder is 6.7wt%, and the rest is high-iron red mud and coal powder. The molar ratio of fixed carbon content in coal powder to oxygen content of iron oxide in high-iron red mud is C / O=1.45. The chemical composition of high-iron red mud in this embodiment is mainly: Fe 2 o 3 35.3wt%, Al 2 o 3 26.1wt%, Na 2 O is 9.2wt%, the rest is SiO 2 , CaO and other impurities; the fixed carbon content of the coal powder is 71.2wt%, the sulfur content is 0.5wt%; the calcium ferrite content in the additive is 95.2wt%.

[0032] 5.0% of the amount of slag is pre-loaded into the empty slag tank in the steelmaking area, and then the steelmaking slag is injected into the slag when the slag is d...

Embodiment 3

[0034] Use a mixer to mix high-speed iron red mud, coking dust, and calcium ferrite powder in proportion and mix evenly, then use a ball press to make a 10-30mm red mud agglomerate, and wait for the agglomerate to dry to a moisture content of ≤ 3% before use. The proportion of calcium ferrite powder is 9.5wt%, and the rest is high-iron red mud and coking dedusting ash. The molar ratio of fixed carbon content in coking dedusting ash to oxygen content of iron oxide in high-iron red mud is C / O=1.3. The chemical composition of high-iron red mud in this embodiment is mainly: Fe 2 o 3 52.4wt%, Al 2 o 3 17.9wt%, Na 2 O is 5.2wt%, the rest is SiO 2 , CaO and other impurities; the fixed carbon content of the coking dust removal ash is 82.2wt%, the sulfur content is 0.7wt%; the calcium ferrite content in the additive is 96.1wt%.

[0035] 4.0% of the amount of slag in the empty slag tank in the iron-making area is pre-filled with red mud lumps, and then the blast furnace slag is inj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com