Hydrophobicity-enhanced heat-vulcanized silicone rubber and preparation method thereof

A technology of thermal vulcanization and silicone rubber, applied in the field of hydrophobic enhanced thermal vulcanization silicone rubber and its preparation, to achieve the effects of improving electric charge, improving elastic modulus, and improving storage modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

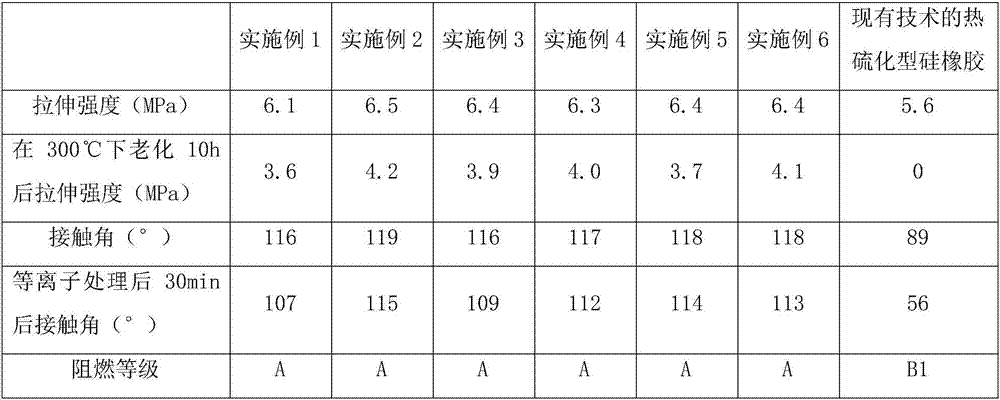

Examples

Embodiment 1

[0025] According to the material ratio of tetramethyldivinyldisiloxane and mixed solution and ethyl orthosilicate is 7.5g:10mL:10g, the volume ratio of adding tetramethyldivinyldisiloxane is 1:10: A mixed solution of 20% concentrated hydrochloric acid, deionized water and ethanol, mechanically stirred, quickly dropwise added tetraethyl orthosilicate, hydrolyzed and condensed, added toluene for extraction and layering, to obtain methyl vinyl silicone resin, according to the cross-linked polyethylene particles and The molar ratio of methyl vinyl silicone resin is 0.5:2. Dry the cross-linked polyethylene particles in vacuum at 80°C for 8 hours, add them to the methyl vinyl silicone resin, stir well, and then press and vulcanize at 180°C 15 minutes, and then a second heat treatment in vacuum at 80°C for 8 hours to obtain a methyl vinyl silicone resin cross-linked with polyethylene particles.

[0026] (2) Add nano-montmorillonite, amorphous alumina and titanium dioxide with a molar...

Embodiment 2

[0029] According to the material ratio of tetramethyldivinyldisiloxane to mixed solution and ethyl orthosilicate is 8g:10mL:15g, the volume ratio of adding tetramethyldivinyldisiloxane is 1:15:25 A mixed solution of concentrated hydrochloric acid, deionized water and ethanol, mechanically stirred, quickly dropwise added tetraethyl orthosilicate, hydrolyzed and condensed, added toluene for extraction and layering, to obtain methyl vinyl silicone resin, according to the cross-linked polyethylene particles and formaldehyde The molar ratio of the base vinyl silicone resin is 1:5, the cross-linked polyethylene particles are dried in vacuum at 80°C for 8 hours, added to the methyl vinyl silicone resin, stirred evenly, and molded and vulcanized at 180°C for 15 minutes , and then heat-treated twice in vacuum at 80°C for 8h to obtain a methyl vinyl silicone resin cross-linked with polyethylene particles.

[0030] (2) Add nano-montmorillonite, amorphous alumina and titanium dioxide with...

Embodiment 3

[0033]According to the material ratio of tetramethyldivinyldisiloxane and mixed solution and ethyl orthosilicate is 7.8g:10mL:12g, the volume ratio of adding tetramethyldivinyldisiloxane is 1:13: A mixed solution of 21 concentrated hydrochloric acid, deionized water and ethanol, mechanically stirred, quickly dropwise added tetraethyl orthosilicate, hydrolyzed and condensed, added toluene for extraction and layering, to obtain methyl vinyl silicone resin, according to the cross-linked polyethylene particles and The molar ratio of methyl vinyl silicone resin is 0.7:3. Dry the cross-linked polyethylene particles in vacuum at 80°C for 8 hours, add them to the methyl vinyl silicone resin, stir them evenly, and press and vulcanize at 180°C 15 minutes, and then a second heat treatment in vacuum at 80°C for 8 hours to obtain a methyl vinyl silicone resin cross-linked with polyethylene particles.

[0034] (2) Add nano-montmorillonite, amorphous alumina and titanium dioxide with a molar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com