Preparation method of rare-earth tantalate high-temperature ceramic

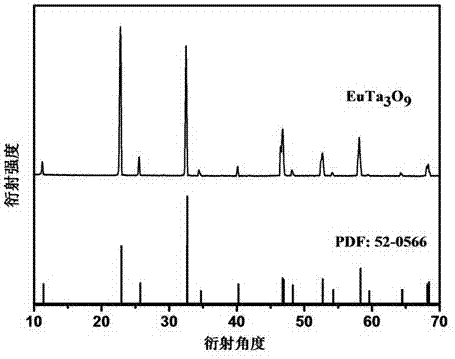

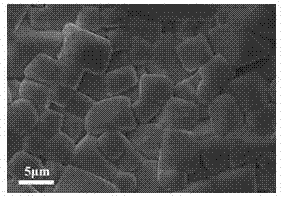

A technology of high-temperature ceramics and tantalate, applied in the field of high-temperature materials, can solve the problems of low density, complex process and many pores, and achieve the effects of high density, high process purity and high sintering activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of rare earth tantalate CeTa 3 o 9 The preparation method of high-temperature ceramics specifically comprises the following steps:

[0031] (1) Weigh 0.01 mol rare earth oxide Ce 2 o 3 Calcined at 600°C for 10h and cooled in the furnace, then added to concentrated nitric acid, and reacted in a water bath at 75°C to obtain Ce(NO 3 ) 3 , reacted until the granular Ce could not be observed by the naked eye 2 o 3 The existence of is the completion of the reaction;

[0032] (2) According to the molar ratio of rare earth elements to Ta in step (1) of 1:3, TaOCl 3 Add it to the reactant in step (1), mix and stir for half an hour, place it in an ultrasonic generator for ultrasonication, and at the same time add concentrated ammonia water drop by drop and vigorously stir it mechanically. Be 10, obtain colloidal solution;

[0033] (3) Filter the sol obtained in step (2), wash it three times with deionized water and wash it twice with alcohol, then keep it in an ov...

Embodiment 2

[0035] A rare earth tantalate NdTa 3 o 9 The preparation method of high-temperature ceramics specifically comprises the following steps:

[0036] (1) Weigh 0.01 mol rare earth oxide Nd 2 o 3 Calcined at 1000°C for 6 hours and cooled in the furnace, then added to concentrated nitric acid, and reacted in a water bath at 70°C to obtain Nd(NO 3 ) 3 , until the granular Nd cannot be observed by the naked eye 2 o 3 The existence of is the completion of the reaction;

[0037](2) According to the molar ratio of rare earth elements to Ta in step (1) of 1:3, TaOCl 3 Add to the reactant in step (1), mix and stir for half an hour, then place it in an ultrasonic generator for ultrasonication, and at the same time add concentrated ammonia water drop by drop and vigorously stir mechanically. The dropping speed of concentrated ammonia water is 1mL / min, and the pH value of the reaction system is controlled. Be 9, obtain colloidal solution;

[0038] (3) Filter the sol obtained in step ...

Embodiment 3

[0040] A rare earth tantalate SmTa 3 o 9 The preparation method of high-temperature ceramics specifically comprises the following steps:

[0041] (1) Weigh 0.01 mol rare earth oxide Sm 2 o 3 Calcined at 900°C for 7h and cooled in the furnace, then added to concentrated nitric acid, and reacted in a water bath at 80°C to obtain Sm(NO 3 ) 3 , until the granular Sm cannot be observed by the naked eye 2 o 3 The existence of is the completion of the reaction;

[0042] (2) According to the molar ratio of rare earth elements to Ta in step (1) of 1:3, TaOCl 3 Add to the reactants in step (1), mix and stir for half an hour, then place in an ultrasonic generator for ultrasonication, and at the same time add concentrated ammonia water drop by drop and vigorously stir mechanically, the dropping rate of concentrated ammonia water is 1.5mL / min, control the pH of the reaction system The value is 11, and a colloidal solution is obtained;

[0043] (3) Filter the sol obtained in step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com