Spinel/metal connector composite material for solid oxide fuel cell and preparation method thereof

A technology of solid oxides and metal connectors, applied in fuel cells, circuits, electrical components, etc., can solve the problems of cathode poisoning and high temperature oxidation resistance, insufficient and other problems, achieve good high temperature electrical conductivity and high temperature oxidation resistance, and inhibit growth , the effect of inhibiting internal diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

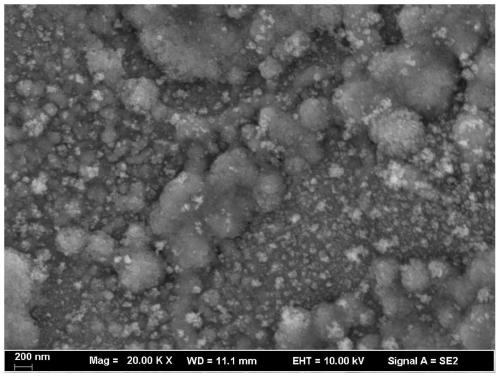

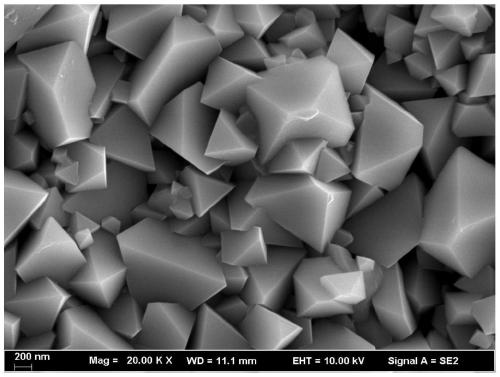

Image

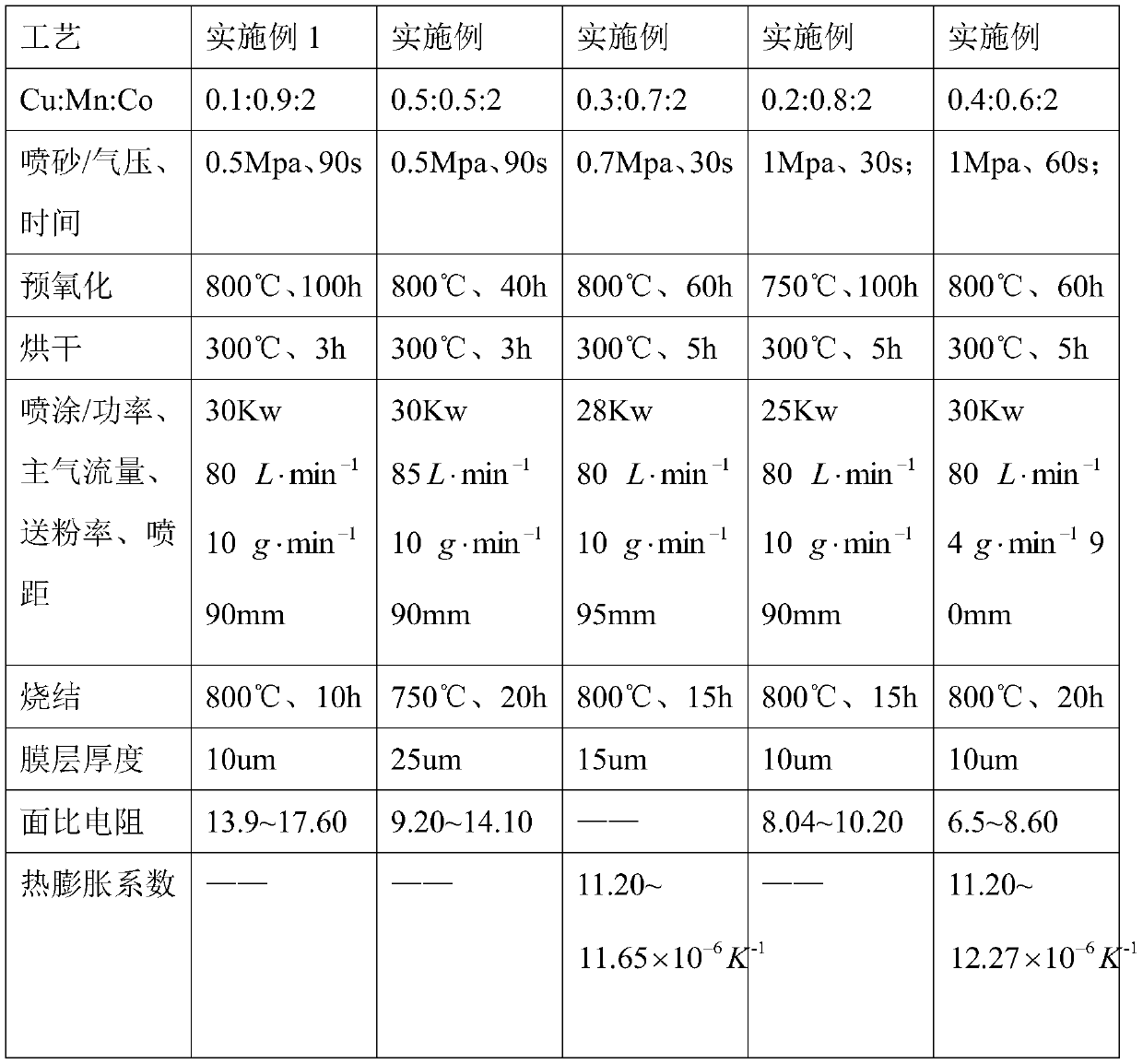

Examples

Embodiment 1

[0022] Preparation of Cu-Mn-Co spinel coating on the surface of solid oxide fuel cell metal connector by plasma spraying:

[0023] (1) Mix 100-mesh Cu powder, 100-mesh Mn powder and 100-mesh Co powder in a molar ratio of 0.1:0.9:2. The mixed powder was ball milled for 3 h using a planetary mill.

[0024] (2) Wire-cut the SUS304 stainless steel substrate, and perform sandblasting roughening on the surface. The sandblasting air pressure is 0.5Mpa, and the time is 90s;

[0025] (3) After surface roughening, put the sample into a box-type resistance furnace for pre-oxidation at 800°C for 100 hours;

[0026] (4) Before spraying, dry the mixed metal powder in an oven at 300°C for 3 hours. Plasma spraying parameters, spraying power 25Kw, main air flow 80L min -1 , powder feeding rate 4g·min -1 , Spray distance 90mm. Working parameters of the spray gun, the horizontal distance of the spray gun sweeping once is 400mm, the longitudinal movement distance of the spray gun is 1mm, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com